Exploring Insulation Materials

Cellular Glass

Cellular glass insulation is a rigid, inorganic,

non-combustible, impermeable, chemically resistant form of glass. It is

available faced or un-faced (jacketed or un-jacketed). Cellular glass is

defined by ASTM as insulation composed of glass processed to form a rigid foam

having a predominantly closed-cell structure. Cellular glass is covered by ASTM

C552, “Standard Specification for Cellular Glass Thermal Insulation,” and is

intended for use on surfaces operating at temperatures between -450 and 800°F.

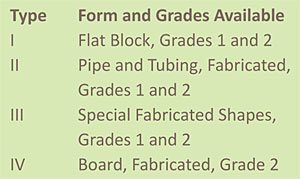

The Standard defines two grades and four types, as follows:

Cellular glass is produced in block form (Type I).

Blocks of Type I product are typically shipped to fabricators who produce

fabricated shapes (Types II, III, and IV) that are supplied to distributors

and/or insulation contractors.

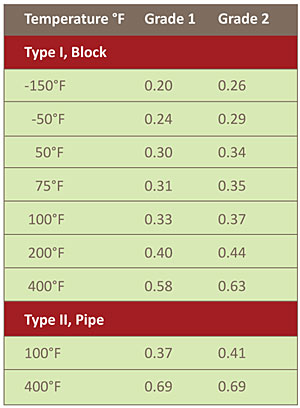

The maximum thermal conductivity is specified, by

grade, as follows (for selected temperatures).

The standard also contains

requirements for density, compressive strength, flexural strength, water

absorption, water-vapor permeability, combustibility, and surface burning

characteristics.

Because of the wide temperature range, different

fabrication techniques are sometimes used at various operating temperature

ranges. Typically, fabrication of cellular glass insulation involves gluing

multiple blocks together to form a “billet,” which is then used to produce pipe

insulation or special shapes. The glue or adhesives used vary with the intended

end use and design operating temperatures. For below-ambient applications, hot

melt adhesives such as ASTM D312 Type III asphalt are usually used. On above-ambient

systems, or where organic adhesives could pose a problem (i.e., LOX service),

an inorganic product such as gypsum cement is often used as fabricating

adhesive. Other adhesives may be recommended for specific applications. When

specifying cellular glass insulation, include system operating conditions to

ensure proper fabrication.