Exploring Insulation Materials

Fibrous Insulations

Fibrous insulations are

composed of small-diameter fibers that finely divide the air space. The fibers

may be organic or inorganic and they are normally (but not always) held

together by a binder. Typical inorganic fibers include glass, rock wool, slag

wool, and alumina silica.

Mineral Fiber (Fiberglass

and Mineral Wool)

Mineral fiber insulations

are defined by ASTM as insulations composed principally of fibers manufactured

from rock, slag, or glass, with or without binders.

Fiberglass and

mineral wool products fall in this category. There is some confusion concerning

the nomenclature used for these materials. Fiberglass products (sometimes

called “fibrous glass” or “glass wool”) and mineral wool products (sometimes

called “rock wool” or “slag wool”) are covered by the same ASTM “mineral fiber”

specifications, and sometimes by the same type and grade. Specifiers are

cautioned to call out both the specific material and the ASTM type and grade

when specifying these products. For example “Fiberglass pipe insulation meeting

the requirements of ASTM C547 Type I, Grade A” or “Mineral Wool pipe insulation

meeting the requirements of ASTM C547 Type II, Grade A.” A number of ASTM

material standards cover mineral fiber products.

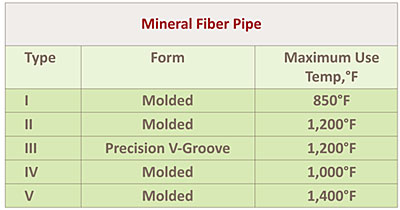

Mineral Fiber Pipe

Mineral fiber pipe

insulation is covered in ASTM C547. The standard contains five types classified

primarily by maximum use temperature.

The standard further

classifies products by grade. Grade A products may be “slapped on” at the

maximum use temperature indicated, while Grade B products are designed to be

used with a heat-up schedule.

The specified

maximum thermal conductivity for all types is 0.25 Btu

in/(hr ft² °F) at a mean temperature of 100°F.

The standard also

contains requirements for sag resistance, linear shrinkage, water-vapor

sorption, surface-burning characteristics, hot surface performance, and

non-fibrous (shot) content. Further, there is an optional requirement in ASTM

C547 for stress corrosion performance if the product is to be used in contact

with austenitic stainless steel piping.

Fiberglass pipe

insulation products will generally fall into either Type I or Type IV. Mineral

wool products will

comply with the higher temperature requirements for Types II, III, and V.

These pipe

insulation products may be specified with various factory-applied facings, or

they may be jacketed in the field. Mineral fiber pipe insulations systems are

also available with self-drying wicking material that wraps continuously around

pipes, valves, and fittings. These products are intended to keep the insulation

material dry for chilled water piping in high-humidity locations. Mineral fiber

pipe insulation sections are typically supplied in lengths of 36 inches, and

are available for most standard pipe and tubing sizes. Available thicknesses

range from ½” to 6″.

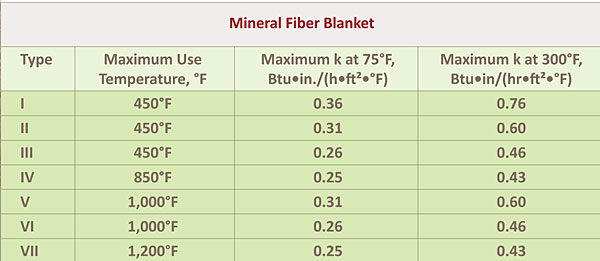

Mineral Fiber Blanket

Mineral fiber blanket

insulation for commercial and industrial applications is covered in ASTM C553.

The standard contains seven types classified by maximum use temperature and thermal

conductivity.

The standard also

contains requirements for flexibility, water-vapor sorption, odor emission, surface-burning

characteristics, corrosiveness, and shot content.

These insulations

are flexible and are normally supplied as batts or rolled blankets. Dimensions

vary, but thicknesses from 1″ to 6″ are typically available. The products may

be specified with various factory-applied facings, or may be ordered unfaced.

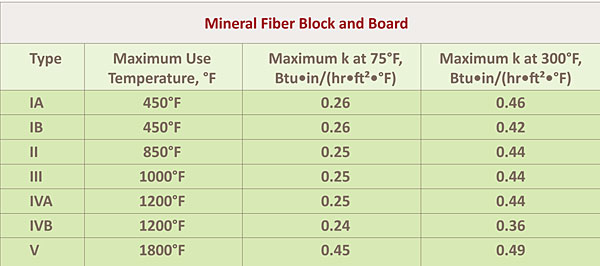

Mineral Fiber Block and

Board

Mineral fiber block and

board insulation is covered in ASTM C612. This standard contains five types classified

by maximum use temperature and thermal conductivity.

Each of these types

is further classified by compressive resistance. Category 1 materials have no requirement

for compressive resistance, while Category 2 materials require a minimum

compressive resistance value. Density is not a performance measure and has been

removed as a requirement in ASTM C612.

The standard also

contains requirements for linear shrinkage, water-vapor sorption,

surface-burning characteristics, odor emission, corrosiveness to steel,

rigidity, and shot (non-fibrous) content. Further, there is an optional

requirement in ASTM C612 for stress corrosion performance if the product is to

be used in contact with austenitic stainless steel. Fibrous glass boards will

generally meet Types I, II, or III. Mineral wool products will generally comply

with the higher temperature requirements for Types IVA, IVB.

These

products are supplied in rigid and semi-rigid board form. Dimensions will vary,

but typical available thicknesses range from 1″ to 4″. The products may be

specified with various factory-applied facings, or may be ordered unfaced.