Exploring Insulation Materials

Polyimide

Polyimide

(PI) insulation is defined by ASTM as lightweight, flexible, open-cell foam for

use as thermal and sound-absorbing insulation in commercial and industrial

environments. PI is manufactured as large rectangular buns, typically 4 ft wide

x 8 ft long x 5-30 inches tall, in a range of densities. Prior to actual

installation, buns are fabricated into various shapes, including flat sheets

and preformed pipe half-shells designed to fit over NPS pipe and tubing.

Complex shapes also can be fabricated to fit tightly around fittings, elbows,

and other equipment. ASTM material specification C 1482 covers PI insulation at

service temperatures from -328°F to +572°F.

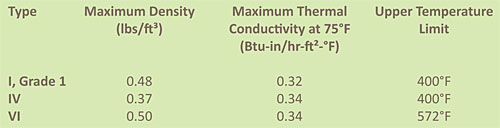

ASTM

C1482 defines the requirements for density, thermal conductivity, acoustic

absorption, thermal stability, flammability, smoke density, smoke toxicity,

chemical resistance, corrosiveness, and mechanical properties. This ASTM spec

lists two grades and four types of PI foam, but the following three types are

most commonly used for commercial and industrial applications.

Key

applications for PI foam include thermal and acoustic insulation for HVAC and

industrial equipment, acoustic duct liner, high temperature pipe insulation,

and expansion joints for cryogenic facilities.

The

use of an appropriate vapor retarder is required in all applications where

condensation could occur. There are a wide variety of vapor retarders, both

films and coatings, that can be specified.