Mechanical Insulation Maintenance: A Proven Investment Opportunity Hidden in Plain Sight

Mechanical insulation in commercial buildings is often hidden behind walls, above ceilings, and in mechanical rooms where only a few have access. In manufacturing or industrial facilities, it is more often exposed to the view of all who venture by. Yet, it seems invisible when energy conservation initiatives are investigated, and it is seldom considered from a return on investment perspective. An investment opportunity that can provide over a 100 percent annual return, help reduce our dependency on foreign energy sources, improve our environment, and stimulate our economy by creating thousands of “shovel ready” jobs is hidden in plain sight.

Industry has been estimating for years that between 10 percent and 30 percent of all exposed mechanical insulation becomes damaged or missing within 1 to 3 years of installation. Over time, and depending on the operating environment and exposure to the elements, that percentage is likely higher. Those estimates have been confirmed by recent data in the industrial sector, and there is no reason to think the commercial sector fares better.

A modest increase in the use of energy-efficient mechanical insulation would allow the United States to quickly generate significant energy demand reductions in the industrial sector, create tens of thousands of green jobs, and help cut the nation’s greenhouse gas emissions.

Assessing the Potential

In 2009 the National Insulation Association (NIA) worked with Oak Ridge National Laboratory (ORNL) and the U.S. Department of Energy’s (DOE’s) Industrial Technologies Program (ITP) to assess possible gains in large and medium industrial facilities. NIA relied on data from DOE’s Save Energy Now program, which conducts energy audits of industrial facilities, to determine the energy and environmental benefits in large and medium plants from mechanical insulation and other initiatives. The assessments identified missing, damaged, or un-insulated areas—maintenance opportunities for mechanical insulation systems. Working again with the ITP, ORNL, and Project Performance Group (PPC), NIA examined a database that included an 83 percent increase in assessments through May 2010. The increased database added to the statistical significance of the data extrapolation and allowed analysis across multiple industry sectors. The 2010 study confirmed the energy and emission reduction, annual rate of return, and job creation opportunities that increased focus on and implementation of mechanical insulation maintenance would create.

NIA and its partners in this effort estimate that mechanical insulation could deliver annually $3.7 billion in energy savings and reduce 37.9 million metric tons of carbon emissions, with a return on investment in 11.3 months (106 percent annual return) from simple maintenance of mechanical insulation in industrial/manufacturing plants. NIA estimated this maintenance work would create more than 27,000 jobs per year for insulation contractors, of which 90 to 95 percent are small businesses, in all 50 states. Those 27,000 jobs support other industry channels with job opportunities of more than 13,000, bringing the total job creation opportunity to 40,000. NIA also noted that 95 percent of materials required for these opportunities are made in the United States, with most of the balance made in Canada.

The Save Energy Now assessments were primarily focused on process heating and steam systems and did not include potential efficiency gains achievable in small industrial plants, the power/utility sector, or the commercial sector (hospitals, schools, government buildings, etc.). Nor do the estimates consider energy efficiency improvements from increased use of mechanical insulation in new industrial or commercial facilities. Using the Save Energy Now assessment data, NIA estimated the maintenance potential in small industrial plants and the power/utility sector.

Said Jef Walker, Supervisor, Partnership Development and Deployment for ITP, “Many of the large and medium plant energy assessments sponsored by the U.S. Industrial Technologies Program have identified mechanical insulation improvements as an important savings opportunity. Improvements in mechanical insulation in large and medium U.S. industrial plants are often a cost-effective opportunity for reducing energy use and energy costs and should be seriously considered.”

These findings confirm once again that mechanical insulation is truly an overlooked and undervalued technology.

The Analysis Approach

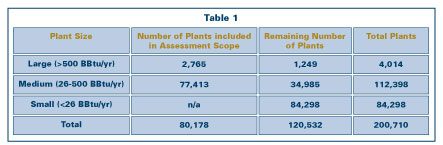

The plants were segregated into three size categories:

- Large Plants, using >500 BBtu/yr, in which the assessments were conducted by independent assessors approved within the SEN program. The Power/Utility industry segment was not included in the scope of the assessments.

- Medium Plants, using 26-500 BBtu/yr, in which the assessments were conducted by the ITP’s Industrial Assessment Centers.

- Small Plants, using <26 BBtu/yr, which were not included in the scope of the ITP assessments.

The numbers of plants within the size categories were determined from the 2002 Energy Information Administration Manufacturing Energy Consumption Survey (EIA-MECS). Those plants were then subdivided into two areas: the plant categories or type that were included in the scope of the ITP assessments and those that were not (Apparel, Leather and Allied Products, Printing, and Furniture). (See Figure 1.)

The assessment results were then extrapolated to the total number of plants in the large and medium size categories.

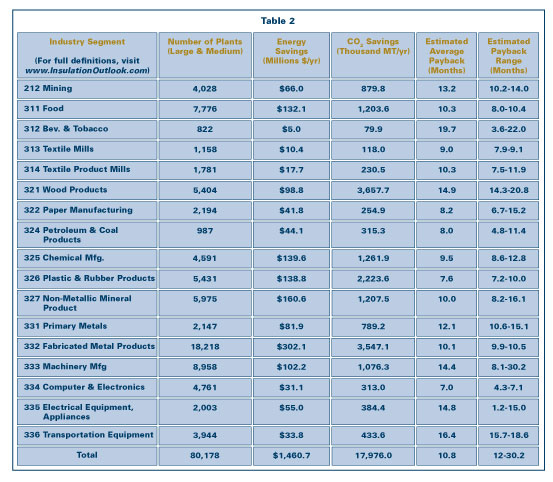

Figure 2 shows the number of large and medium plants by industry segment and their potential energy cost savings, CO2 reduction, and estimated payback for investing in mechanical insulation maintenance.

Using the Medium Plant category findings, NIA estimated the Small Plant category to resemble the Medium Plant findings but limited the savings to 50 percent of Medium Plant totals. Some may believe that is conservative, given that the number of small plants is 75 percent of the Medium Plant total and in many cases small plants pay less attention to energy efficiency than larger facilities do. Others may have a different opinion of that estimate.

Consistent with the 2009 report, NIA estimated there were 6,483 utility plants not included in the scope of the Save Energy Now assessments. The number of Public Utility/Power plants was determined by examination and extrapolation of data from the Energy Information Administration’s 2000 Existing Capacity at the U.S. Electric Utilities & 2007 Energy Capacity by Existing Source. (Hydroelectric and wind units were not included.) NIA then estimated the opportunity for those plants to be of similar magnitude to the opportunities identified in the Large Plant assessments.

The Bottom Line: Mechanical Insulation Maintenance is a Proven Investment Opportunity Hidden in Plain Sight

By extrapolating from the results of more than 1,100 assessments and insulation recommendations from the Save Energy Now independent assessments of Large and Medium size plants, it is estimated that mechanical insulation could:

- Deliver annually $3.7 billion in energy savings

- Reduce 37.9 million metric tons of carbon emissions

- Provide a return on investment in 11.3 months (106 percent annual return)

- Create more than 27,000 jobs per year for insulation contractors, of which 90 to 95 percent are small businesses, in all 50 states.

Those 27,000 jobs support other industry channels with job opportunities, bringing the total job creation opportunity to 40,000. Of materials required for these opportunities, 95 percent are made in the United States, with most of the balance made in Canada.

Even more impressive, these estimates are based primarily on the results of assessments on process heating and steam systems. They do not include manufacturing processes or other opportunities in the industrial or manufacturing sector or any opportunities in the commercial sector. Just how big is the total opportunity: $5, $7, or $10 billion? The answer is not known, but it is large, with a phenomenal return.

Barriers to Implementing an Aggressive and Continuous Mechanical Insulation Maintenance Process

Insulation can reduce energy consumption and greenhouse gas emissions, increase available carbon credits, be an important part of sustainable design initiatives, be part of a safety program, increase manufacturing productivity, eliminate or reduce corrosion under insulation, control condensation and mold growth, and provide an unrivaled return on investment. So why is it a “forgotten technology”? Following are some common reasons.

- Many decision makers lack detailed knowledge about mechanical insulation systems, their benefits, and the risk of not maintaining them in an effective and timely manner.

- Every plant, facility, or company needs a mechanical insulation “champion.”

- Good or best practices in one unit/plant need to be widely diffused within and between organizations.

- Decision makers need motivation to allocate attention and resources. Financial modeling should be considered as part of the decision process.

- Timely and effective insulation maintenance is an investment, not an expense. The damage or cost caused by reduced focus on mechanical insulation is often not identified in technical and/or financial terms until it may be too late.

- There is usually pressure from competing and often more “glamorous” initiatives. Mechanical insulation is not “sexy” to many. But, a 100 percent annual return is sexy in any language.

This 2010 updated study confirms that the cost of a good insulation system can be easily calculated. The cost of an underperforming insulation system is an investment opportunity that should not be overlooked.

To take full advantage of this forgotten technology, it is essential to begin thinking differently about mechanical insulation. While mechanical insulation maintenance is neither sexy nor an exciting topic of discussion, it is an opportunity hidden in plain sight. When all the benefits are considered, the decision should be easy.

Acknowledgements and Information about the Mechanical Insulation Education and Awareness Campaign

The information in this article is a direct result of the DOE-ITP’s Mechanical Insulation Education and Awareness Campaign (MIC). Appreciation is extended to all who have worked and continue to work to develop this type of information and provide education about all aspects of mechanical insulation in all industry segments.

The MIC is a program to increase awareness of the energy efficiency, emission reduction, economic stimulus, and other benefits of mechanical insulation in the industrial and commercial markets. Mechanical insulation’s potential to play a significant role as a tool to reduce energy intensity is immense. However, the lack of sufficient data to support its energy efficiency potential, combined with a deficient understanding of what mechanical insulation is and how it could be used, impedes policy makers and actors in industrial and commercial sectors in making a supportable case for increased use and maintenance of mechanical insulation. While current uncertainties hinder mechanical insulation from playing a larger role in energy efficiency decisions, the Mechanical Insulation Education and Awareness Campaign was created to meet two key initiatives:

- Educate industry on and promote the benefits of mechanical insulation by providing practical data and case studies outlining potential energy savings provided by mechanical insulation installation;

- Launch an aggressive public education and awareness campaign on the heels of President Obama’s call to combat climate change and improve energy efficiency.

As part of efforts by the DOE-ITP to improve energy efficiency of the U.S. industrial and commercial sectors, Project Performance Corporation and NIA, in conjunction with its alliance with the International Association of Heat and Frost Insulators and Allied Workers, are working together to design, implement, and execute the MIC. Save Energy Now is a national initiative of the ITP to drive a 25 percent reduction in industrial energy intensity in 10 years. For more information, visit www1.eere.energy.gov/industry/. To learn more about NIA, visit www.insulation.org. To learn more about the International, visit www.insulators.org.