Mechanical Insulation Simple Calculators: A Guide to the Estimate Time to Freezing for Water in an Insulated Pipe

As a part of

efforts by the Department of Energy’s Advanced Manufacturing Office to improve

the energy efficiency of the U.S. industrial and commercial sectors, the

National Insulation Association (NIA), in conjunction with its Alliance

partners, worked to design, implement, and execute the Mechanical Insulation

Education & Awareness Campaign (MIC).

As we have discussed in

previous articles in this series, the MIC is a program to increase awareness of

the energy efficiency, emission reduction, economic stimulus potential, and

other benefits of thermal insulation for mechanical systems. An integral component

of the MIC was the development of a series of “Simple Calculators.” The

calculators, listed at below, provide users with instantaneous information on a

variety of insulation applications in the industrial/ manufacturing and

commercial markets.

- Condensation Control—Horizontal Piping

- Energy Loss, Emission Reduction, Surface

Temperature, and Annual Return - Financial Returns

- Estimate Time to Freezing for

Water in an Insulated Pipe - Personnel Protection for Horizontal Piping

- Temperature Drop for Air in an Insulated Duct or Fluid in an

Insulated Pipe

The calculators are available

online as part of the National Institute of Building Sciences’ Mechanical

Insulation Design Guide (MIDG), www.wbdg.org/midg

.You can also access

them through a link on NIA’s website: www.insulation.org. The calculators are fast, free, and

functional tools that make it easy to discover energy savings, financial

returns, and other information for the design of mechanical insulation systems

for above-or below-ambient applications.

This article will provide an

overview and guide to use the Estimate Time to Freezing for Water in an

Insulated Pipe Calculator.

Estimate Time to Freezing for Water in an

Insulated Pipe Calculator

This calculator estimates the time it takes for a

long, fluid-filled pipe (no flow) to reach freezing temperature.

It is important to recognize

that insulation retards heat flow; it does not stop it completely. If the

surrounding air temperature remains low enough for an extended period,

insulation cannot prevent freezing of still water or of water flowing at a rate

insufficient for the available heat content to offset heat loss. Well-insulated

pipes, however, may greatly extend the time to freezing. Clean water in pipes

usually supercools several degrees below freezing before any ice is formed.

After freezing begins, the latent heat of fusion must be removed. Note that the

calculator estimates the time to reach the freezing temperature of water (32°F)

and does not address the supercooling or latent heat of water. The calculator

also ignores the thermal resistance and capacitance of the pipe wall. This

calculator is based on the approach published in the 2009 ASHRAE Handbook of

Fundamentals (Chapter 23, Equation 1). For further information on this topic

and the calculator, please refer to the MIDG, Design

Objectives—Freeze Protection web page.

Calculator Inputs

The calculator requires Input Information for 6

input variables. Results are updated as each input variable is entered.

Following are the instructions and additional information for each input

variable.

- Line 1. Initial Temperature of Water in Pipe, °F 42

The default value

is 42°F; however, you should enter the actual initial temperature for the water

in the pipe. - Line 2. Ambient Temperature, °F -18

The default value

is -18°F; however, you should enter the expected ambient temperature in

Fahrenheit. It is suggested you use a realistic worst-case scenario. - Line 3. Select Pipe Sizes or Tubing Sizes, Pipe Sizes, NPS

The default

selection is Pipe Sizes, NPS; however, you should use the drop-down box to

select either Pipe or Tubing applications. - Line 4. Select Nominal Pipe or Tubing Size, 6

The default value

is a nominal pipe size of 6″; however, by using the drop-down box you can

select a pipe or tubing size from ½” to 24″. - Line 5. Select Insulation Thickness, 2

The default

thickness is 2″; however, you should use the drop-down box to select the

desired thickness. It offers a range from .5 to 4 inches. - Line 6. Select Insulation Material, Polyisocyanurate (-297°F

to 300°F)The default

material is Polyisocyanurate; however, you may use the drop-down box to select

1 of 8 insulation materials: Calcium Silicate, Cellular Glass, Elastomeric,

Fiberglass, Mineral Wool, Polyethylene, Polyisocyanurate, or Polystyrene. You

will note each of the material options contains a general operating temperature

range. The Simple Calculators do not have the capability of utilizing

user-supplied thermal curves. Thermal conductivity values for the listed

materials are based on ASTM material specification values.

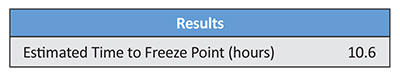

Based

upon the information variables provided, the Results section displays the

estimated time to freeze point in hours; in this example the result was 10.6

hours.

In

summary, the Simple Calculators are intended to provide the user with online,

easily accessible, snapshot information on some the most frequently asked about

benefits and design considerations of mechanical insulation systems. They do

not address every insulation material or application condition, but they do

provide guidance in a number of applications that are useful for the testing

and evaluation of insulation projects and materials.

Whether you need basic insulation information or are

designing a complex insulation system, the MIDG, found online at

www.wbdg.org,

is an excellent resource for the novice or the experienced user. The MIDG

is continually updated and always has the most current and complete

information, including the convenient Simple Calculators, which were designed

to make common mechanical insulation calculations easy for users of all levels.

These tools can be very helpful in designing a mechanical insulation system and

allow the user to easily determine the many benefits and value of thermal

insulation for mechanical systems.