Perspectives on Water Vapor Permeance of Mechanical Insulation Systems

Insulation

material comparison often involves contrasting the physical properties of the

materials as represented on the products’ data sheets. Going through this exercise,

it is important to be sure that the physical properties being compared are

tested to the same test method and procedure, and the values are expressed in

the same units. If not, one is comparing apples to oranges, resulting in an

inaccurate analysis of materials. It also is essential to understand the effect

that the physical property will have on the insulation performance in relation

to the units of measure.

A good example of the importance of understanding physical

property terms is in defining a material’s ability to resist penetration of

moisture from the air. Water vapor permeability and permeance are both measures

of a material’s ability to resist penetration of moisture from the air. The

terms are defined in ASTM Standard C168 ? 10, “Standard Terminology Relating to

Thermal Insulation” as follows:

Water

vapor permeability – the

time rate of water vapor transmission through unit area of flat material of

unit thickness induced by unit vapor pressure difference between two specific

surfaces, under specified temperature and humidity conditions.

Water

vapor permeance – the

time rate of water vapor transmission through unit area of flat material or construction

induced by unit vapor pressure difference between two specific surfaces, under

specified temperature and humidity conditions.

Permeability is measured in units of perms-inch and is used

to compare materials that are typically used in a variety of thicknesses (¼” or

greater). Permeance is measured in units of perms and is used to describe

thinner materials (e.g., jacketing products) that are used in the field in the

exact thickness at which the material is tested.

A similar relationship exists between the terms used to

define thermal conductivity: k-factor and R-value. The unit to describe k-factor

is defined at a standard thickness of per 1″. This allows an end user to

compare materials on an equal basis, regardless of thickness. In contrast,

R-value is a measure of the material in the thickness it is used in the field,

and varies depending on the referenced thickness. In regards to units used to

measure moisture penetration resistance, permeability is similar to the

k-factor, and permeance is similar to the R-value. A material with a

permeability listed as 1.0 perm-inch would have a permeance of 1.33 at ¾”

thickness (1.0/.75 = 1.33). For moisture penetration resistance values, the

smaller the number, the better the value.

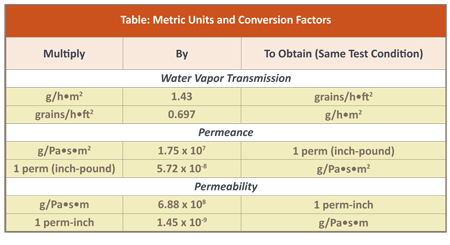

Derived moisture penetration resistance results can be

converted from one term to the other using appropriate conversion factors

(referenced in the table on page 29).

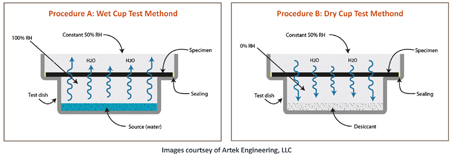

A common test method to measure this property is ASTM E96,

“Standard Test Methods for Water Vapor Transmission of Materials.” Two test

procedures (see images above) are called out in the Standard: wet cup

(Procedure A) and dry cup (Procedure B). Both procedures start by conditioning,

measuring thickness, and weighing the sample. For the wet cup method, the

sample is placed over a pan with water in it and the edges sealed. For the dry

cup method, the sample is placed over a pan with a desiccant in it and the

edges sealed. The pans are then placed in an environmental chamber at a

specified temperature and humidity, and weighed daily, until the weight gain or

loss reaches equilibrium (shown in the chart on page 29). At this time, the

permeability or permeance of the material can be established. For some

insulation or jacketing materials, the procedure used can make a slight

difference in the stated value. Hence, to be sure one is comparing apples to

apples, one should use values obtained from the same procedure (which should be

stated on the product’s technical data sheet).

It also is important to understand the

significance of both the physical property itself and the value stated. One of

the key determining factors to consider when evaluating the significance of a

test value is the precision of the test. A result that goes beyond what the

test can accurately measure does not provide added value. Also, the definition

of what constitutes a good value, “low perm” in this case, often changes over

time. Further, within the permeability or permeance value, one should consider

the value of the entire system?specifically, how much weight should be placed

on the permeability of the material itself versus the permeability of the seams.

For example, aluminum jacketing has a very low permeance, but if the seams are

not properly sealed, the system loses much of its integrity so that no matter

how good the jacketing is, the overall insulation system may not perform as

expected. In most cases, slight differences in permeability would require many

years to make a difference in the performance of the system, even if the

percentage change may seem large. Other factors probably would play a much

greater role, such as damage to the jacket or insulation.

Another key point to understand is what

effect the property will have on the performance of the insulation.

Permeability is primarily an issue with insulation on low-temperature lines

where humidity is high over long periods of time. On systems that do not have

these conditions, permeability will not be a key consideration. The lower the

line temperature and the higher the humidity, the greater the importance will

be. Hence, in Florida and the Gulf States, it can be a key factor. Over time,

with highly permeable materials, air with moisture will come in contact with

the cold pipe and form condensation between the pipe and the insulation. The

moisture creates wet insulation, which increases the chances for pipe

corrosion, mold growth, and degradation of the insulation’s thermal

conductivity, resulting in insulation and system failure. This situation is

severe and would warrant removal of the insulation. However, this is a long,

slow process taking years to develop. In contrast, if there is evidence of

moisture between the insulation and the pipe in a short period of time, the

cause is almost always an open seam or termination point where moisture-laden

air can travel unabated to the cold pipe and form condensation.

In summary, there are typically several ways to describe a

material’s performance, including its ability to resist penetration of moisture

from the air. When comparing products or determining if a material meets a

specification requirement, one must pay careful attention to the units and identified

test method. There are many reasons why it is important to understand the

physical property terms used to describe or compare materials and to be sure

one is comparing like terms expressed in the same units. Further, it is vital

to understand the effect that a particular property has on the performance of

the insulation system.