World’s Largest Penguin Playground Opens at Detroit Zoo with Help of Insulation

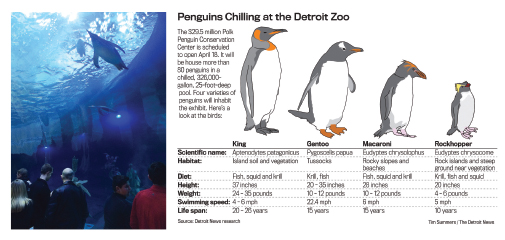

The world’s largest penguin playground opened recently at the Detroit Zoo. More than 80 penguins of 4 varieties—King, Gentoo, Macaroni, and Rockhopper—are housed there and will stay comfortably cold year round thanks to local Michigan insulation companies and the use of fiber glass, elastomeric, and spray foam insulation.

The zoo’s new 33,000 square foot, $30 million Polk Penguin Conservation Center opened April 18, 2016, with a blue carpet walk by the feathered stars of the show as they made their way from the old Penguinerium to their new home. The aquatic birds, who can can spend 80% of their lives in the water, are in for a treat as the new facility includes a tank that holds 326,000 gallons of water (10 times more than their old home) and allows for deep diving up to 25 feet.

The Detroit Zoo web page describes the exhibit as “inspired by Sir Ernest Shackleton’s legendary Antarctic expedition and epic crossing of the Drake Passage. The penguin center evokes the harsh and visceral ice world of the southern continent, recreated in a 360-degree 4-D entry experience that includes blasts of polar air and sea mist. A video and sound feature called projection mapping depicts a phenomenon known as iceberg calving—one of nature’s most dramatic spectacles where icebergs split and send massive cascades of ice crashing into the sea.” Visitors can also make their way through 2 transparent tunnels that run through the water environs, enabling an up-close look at the penguins.

While temps may hover around 70 degrees for visitors winding their way through the 4-dimensional simulation of Shackleton’s ill-fated expedition in Antarctica’s iceberg littered waters, the penguins on the other side of the glass wall must stay a near-freezing 37 degrees at all times.

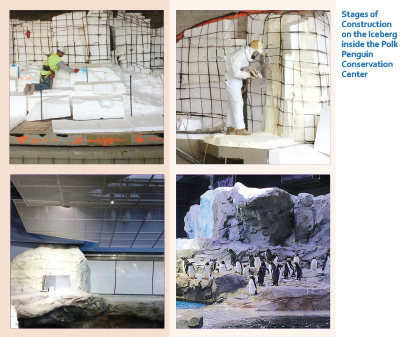

“Everything, including the constant climate, mimics a large tabular iceberg,” says Anton Cornellier, President of Stony Creek Services, Westland, Michigan–based insulation applicators. “The architect, Albert Kahn Associates, designed an amazing iceberg-like exterior, and Seattle-based designers from Jones & Jones Architects made sure the interior seascape had all the proper features like ice and rocks that we can only really see now that it’s complete. It was our job to make sure the insulation worked so the birds stay cold and healthy.”

Cornellier said the architectural firm chose a versatile, spray-in-place, high-performance insulation for the building because “Spray polyurethane foam (SPF) insulation is originally a liquid, so it can be applied to almost any shape. . . it’s a liquid when applied, so it fills every crack and penetration in the substrate, then expands and cures in place to create a monolithic envelope. In this case, they were concerned about consistency of temperature and condensation. [The insulation] has amazing R-value, is a water and air barrier, helps with soundproofing, and will last the life of the building.”

Cornellier said his company spray-applied 2 inches of spray foam to the exterior masonry cavity walls of the building and to the display frames in the habitat before adding a carved concrete stone façade mimicking the rocky terrain of coastal Antarctica. “Our part of the job took about a month and was done in phases. To see the entire exhibit open and working is just breathtaking. It’s definitely the way zoo animal habitats should be built and work. That we worked on the largest facility in the world is a real honor for Stony Creek. That it is so beautiful and the penguins have such a well-designed real-world habitat is something I’ll always feel good about. I’m sure my family and I will visit the birds quite often.”

In regard to the mechanical systems, Rival Insulation, LLC, a local Michigan full-service insulation contractor, was responsible for insulating all plumbing, piping, ductwork, and HVAC to ensure the appropriate temperature for the penguins as well as the zoo’s visitors. The project included the insulation of approximately 4,000 lineal feet of piping and more than 10,000 square feet of ductwork. Fiber glass was used on plumbing, piping, and interior ductwork; flexible elastomeric was used on refrigerant piping; and aluminum jacketing was used on exterior ductwork and piping. Christopher Tremberth, Co-founder and CEO of Rival Insulation, LLC, said in regard to the installation, “It was great to work on such a landmark project. While mechanical insulation’s green benefits such as energy conservation are well known, I’m glad we were able to work on a project that directly helps wildlife.”

The Polk Penguin Conservation Center took 4 years to plan and build. The designers and zoo staff went to great lengths—and distances as the team visited penguins in their natural environment in Antarctica—to create the most advanced aquatic bird habitat in the world for the Detroit penguins, and the people who visit them.

Copyright Statement

This article was published in the July 2016 issue of Insulation Outlook magazine. Copyright © 2016 National Insulation Association. All rights reserved. The contents of this website and Insulation Outlook magazine may not be reproduced in any means, in whole or in part, without the prior written permission of the publisher and NIA. Any unauthorized duplication is strictly prohibited and would violate NIA’s copyright and may violate other copyright agreements that NIA has with authors and partners. Contact publisher@insulation.org to reprint or reproduce this content.