A Different Perspective: Double Layer vs. Single Layer on Boiler Walls

Boiler insulation practices have moved from a single layer to a dual layer of the same total thickness in recent years. However, this dual layer trend has a downside: higher installation costs and the potential for inexperienced contractors or self installers to cut corners when installing insulation. It’s time to return to using single layer insulation on power boilers and employing professional insulation contractors.

The construction of new steam-generating boilers has been slowed in part by today’s economic environment and regulatory uncertainty. Although not tracked by the National Energy Technology Laboratory (NETL), rising construction costs—now over $1 billion for a moderately sized new plant—can play a significant role in delaying the start of a new project.

The central building block of any new fossil fuel–fired plant is the boiler island. Every possible means should be explored to lower the construction cost. One particular means to reduce the cost of the construction is improving the insulation on steam-generating boilers.

Many in the power industry believe that a smarter and more economical insulation design on steam-generating boiler walls should be explored, especially when considering the rising cost and reduced availability of qualified field labor. One specific way to reduce costs is to use or to specify a single layer of insulation.

Today, the power industry accepts the assertion that a double layer application in lieu of one single layer of insulation on membrane boiler walls creates a better insulation system.

That, however, is not always the case. Single-layer application on membrane boiler walls was a common practice within the power industry for many years. In fact, almost every boiler built between 1968 and the middle 1980s in the United States, regardless of the manufacturer, specified single-layer application for their boiler wall insulation unless the thickness required by operating and surface temperatures was greater than 4 inches (assuming a mineral wool board type insulation). Double layer application during that time was typically specified only when it was a special requirement by the end user or the insulation material was not available in a single layer by the insulation manufacturers.

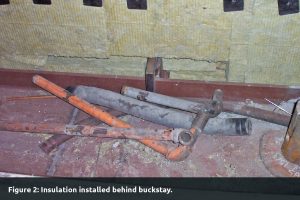

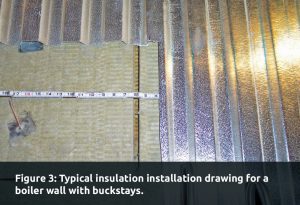

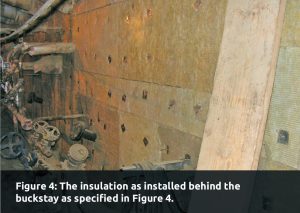

In designing a boiler, the Original Equipment Manufacturer (OEM) must establish the cold-surface temperature, or acceptable heat loss, on the boiler walls. This temperature typically ranges from 120°F to 140°F, although many accept 130°F as an industry standard today. Next, the heat loss on the boiler walls at that temperature and the boiler casing temperature (based on the size of the boiler and superheater surface required to meet a desired steam outlet and exit gas temperature) is used to calculate the thickness of a given insulating material. Then the distance between the boiler water wall tubes and the buckstays (integral structural support of the boiler) is set to accommodate the insulation thickness.

The boiler warranty is often tied to how close the OEM meets the specified cold surface temperature, steam outlet temperature, and gas outlet temperature. Therefore, the insulation specifications selected by the OEM and the proper installation procedures are very important in determining the final boiler performance. That is why every aspect of the insulation selection (such as material and installation cost, K-value at mean temperature, shrinkage, and material thickness availability, etc.) must be closely analyzed.

All boiler manufacturers specify and document the insulation thickness and material requirements on their steam-generating boilers. Each has developed company standards for the type of insulation and the acceptable application procedures for installing the insulation. These standards and application procedures are provided with each boiler they sell whether the insulation was in their scope of supply or not. This is still true today.

The decision to use a single or double layer of insulation during construction of the boiler is not tied to the boiler performance warranty. In fact, for a given surface temperature and boiler wall temperature, the boiler performance is not affected by the number of insulation layers installed on the boiler walls as long as the total thickness was the same. In other words, it doesn’t matter if a single or double layer of insulation is specified—the total thickness is what governs insulation performance. The decision to specify single layer over double layer is strictly an economic decision made by the OEM.

Single-thickness insulation has a long and successful history in the power generation industry. During the period from 1964 (starting with the membrane tube wall construction) to 1990, one particular boiler manufacturer built and sold over 250 radiant power boilers, 150 universal pressure boilers, 200 industrial boilers, and 100 process/Kraft recovery boilers. All of these boilers were designed and constructed with a single layer of mineral wool board on the boiler walls and a cold surface temperature of 130°F. Significantly, neither the OEM nor the power plants have reported any problems meeting boiler performance caused when using only a single layer of insulation on all of these units.

Costly Changes

In the mid-1990s, several OEMs and purchasers changed their insulation standard to require a double layer of insulation—with the same overall thickness—on their boiler walls. The reasons behind this specification change remains murky to many of those who work within the industry designing and specifying insulation systems.

If this change was made as an energy-saving decision, then 1 layer will perform as well as 2 layers at the same overall thickness, assuming the insulation is installed correctly by a professional insulation contractor.

Some argue that a double-layer application is better than single layer because it eliminates gaps between the individual insulation pieces and reduces the chances for hot spots on the outer lagging or casing surface. This is a labor supervision issue and not a design specification issue. Every OEM installation standard clearly states that gaps 1/16” or greater between boards or blankets are not acceptable regardless of how many layers of insulation are being installed. These standards require that all insulation be tightly butted against each other and any gaps between insulation must be filled with appropriate insulating cement before the outer lagging or casing is installed. These standards are independent of whether the insulation is applied in a single or double layer.

Using a double layer of insulation has several drawbacks. First, the cost to use double layer versus single layer insulation on boiler walls increases the cost of material for additional fasteners and labor. For example, a boiler with 100,000 square feet of water wall surface covered with a 4-inch-thick double layer mineral wool board meeting ASTM C-612 type IVB—in lieu of a single board of the same thickness—raises the cost to build that boiler by approximately $200,000 (this will vary depending on region and labor market). For the 22 new coal-fired units built in the last 10 years, this could amount to over 4 million dollars in increased construction cost.

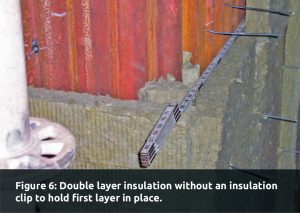

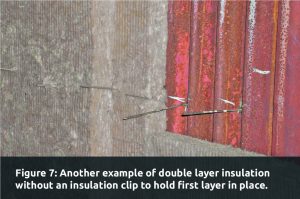

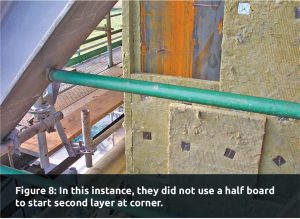

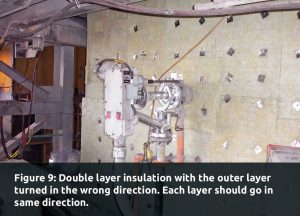

Also, going to a double layer often increases the number of gaps and can increase the incidence of improper insulation applications. This situation takes place when the first layer of insulation is installed in an improper manner followed by the second layer that forever hides the poor craftsmanship—this is part of why hiring an experienced, qualified, and knowledgable contractor (such as one of the National Insulation Association’s members) is so important. Unfortunately, with self-installers this occurs all too frequently and only good contractors and supervisors will prevent this situation from becoming an epidemic on a job site. Figures 5–12 illustrate how the improper installation of a double layer of insulation occurred during construction of a power station. Each of these photos violates the OEM installation specification.

Final Thoughts

There is a time and a place to use double layers of insulation. For example, double layers are appropriate when burying external stiffeners and channels, or where the hot face temperature requires more than 4 inches of insulation to maintain a given cold face temperature. These situations are atypical and can easily be handled in the field as exceptions.

The increased cost of applying 2 layers of insulation plus the increased instances of poor insulation performance caused by poor field supervision and inexperienced installation labor does not support the current industry trend toward double layers of insulation.

Copyright Statement

This article was published in the June 2017 issue of Insulation Outlook magazine. Copyright © 2017 National Insulation Association. All rights reserved. The contents of this website and Insulation Outlook magazine may not be reproduced in any means, in whole or in part, without the prior written permission of the publisher and NIA. Any unauthorized duplication is strictly prohibited and would violate NIA’s copyright and may violate other copyright agreements that NIA has with authors and partners. Contact publisher@insulation.org to reprint or reproduce this content.