Thank you to the 7 companies who participated during out 2024 Fall Summit Project Showcase! The goal of this showcase was to highlight the creativity, artistry, and craftsmanship of contractor projects representing mechanical and industrial insulation systems.

Winners

1st Place Winner

Insul-Tech, Inc.

Mission Critical Data Center

This project was part of “Data Center Alley” and was a large project with unique challenges. The first phase of this project included more than 3,000 feet of very large 36” pipe and 6,500 feet of 24” pipe, and it needed to be complete within 12 months of contract award. Finalizing the insulation specifications with engineers became imperative, as well as identifying and minimizing insulation material lead times as best we could. Due to the large diameter of the pipes, and the quantity of insulation materials needed, we worked with the manufacturer to fabricate and deliver pipe covering for that size. For all fittings, 90s and 45s, and flange and valve covers, we fabricated those in-house for the entire project. Our relationships within NIA and this industry proved to be invaluable assets to make and move these sizes and quantity of material quickly. With help from our suppliers, we were able to complete our portion of the project on schedule.

- Industry Segment: Commercial

- Type of Plant/Facility: Commercial Buidling

- Temperature Range: Below-Ambient System

- Region: Northeast

- Goals for the Project: New Construction

2nd Place Winners

Fit Tight Covers

Renewable Natural Gas Facility at a Landfill

This project was completed at a renewable natural gas landfill site, a growing sector in sustainable energy. The owner/operator, who also served as the construction manager, selected removable insulation covers for all flanges, valves, and equipment to address concerns about startup costs and maintenance efficiency. These custom-designed covers facilitated easier removal, repair, and replacement of insulation during the critical startup phase when bolts on piping items required retorquing and systems were being adjusted to optimize performance. Even the adsorber vessels and loop piping were insulated with these removable covers, providing an additional layer of protection. This strategic choice helped prevent potential damage and reduced repair needs during the routine replacement of the media contained within the vessels, ultimately contributing to the overall durability and efficiency of the site’s operations.

- Industry Segment: Industrial

- Type of Plant/Facility: Renewable Natural Gas at a Landfill

- Temperature Range: High- Temperature System

- Region: Midwest

- Goals for the Project: New Construction, Energy Savings, Process Control, and Personnel Protection

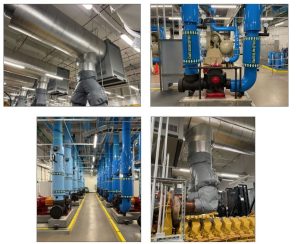

Performance Contracting, Inc.

Data Center

This project involves the renovation of an existing data center in Birmingham, Alabama, focusing on upgrading the cooling and emergency power systems. The upgrades include the replacement of 8 chillers, 8 cooling towers, 24 pumps, 10 emergency generators, and several computer room air conditioning (CRAC) units. These enhancements aim to improve the efficiency and reliability of the data center’s infrastructure, ensuring optimal performance and minimizing downtime. The project also includes the implementation of advanced monitoring and control systems to provide real-time data on the performance of the new equipment. This comprehensive upgrade will not only enhance the data center’s operational capabilities but also contribute to energy savings and reduced environmental impact.

- Industry Segment: Commercial

- Type of Plant/Facility: Data Center

- Temperature Range: Below-Ambient System

- Region: Southeast

- Goals for the Project: Energy Savings, Process Control, Condensation Control, and Personnel Protection

Participants

L.C. Insulations, Inc.

Medical Facility Testing Lab

Medical facility testing lab requiring the insulation of several mechanical systems to support the facility’s mission. These systems include steam, steam condensate, chilled water, glycol, hot water, humidification systems, sterilization systems, HVAC duct systems, and various domestic water and drainage systems.

- Industry Segment: Commerical

- Type of Plant/Facility: Medical Facility

- Temperate Range: Below-Ambient System, Above Ambient System, and High-Temperature System

- Region: Northeast

- Goals for the Project: New Construction, Energy Savings, Emission Reductions, Process Control, Condensation Control, and Personnel Protection

Gribbins Insulations & Scaffolding

Aluminum Manufacturing Facility

This industrial project took place at an aluminum manufacturing facility in the Midwest and focused on insulating a mass flow decoater system. The decoating process uses advanced technology to remove coatings from scrap aluminum and cans, enabling the recovery of clean, high-quality aluminum. The system efficiently eliminates contaminants such as paint, lacquer, and plastic coatings, ensuring the recycled aluminum is of superior quality and ready for various industrial applications. Our insulation work enhances the system’s performance by optimizing energy efficiency and maintaining safe operating temperatures, contributing to a more sustainable recycling process.

- Industry Segment: Industrial

- Type of Plant/Facility: Aluminum Manufacturing

- Temperature Range: High-Temperature System

- Region: Midwest

- Goals for the Project: New Construction, Energy Savings, Process Control, and Personnel Protection

Luse Thermal Technologies, Inc.

Pharmaceutical Manufacturing

The project required insulation for chilled water and steam systems to support the pharmaceutical facility's mission. These systems ensure efficient temperature control, energy conservation, and operational safety. The team worked in collaboration to meet the stringent requirements of the pharmaceutical environment, adhering to the Engineer's specifications, cleanroom protocols, and industry standards. This insulation work plays a vital role in maintaining optimal environmental conditions for pharmaceutical production, ensuring smooth facility operation and regulatory compliance.

- Industry Segment: Food Processing

- Type of Plant/Facility: Pharmaceutical Manufacturing

- Temperature Range: Process Chilled Water, Steam, and Poly-Iso

- Region: Midwest

- Goals for the Project: Process Control

International Asbestos Removal, Inc.

Commercial Office Building Mechanical Room

Insulated the diesel exhaust and muffler for the emergency backup generator.

- Industry Segment: Commercial

- Type of Plant/Facility: Commercial Office Building

- Temperature Range: High-Temperature System

- Region: Midwest

- Goals for the Project: New Construction, Energy Savings, Process Control, and Personnel Protection