Commercial Energy Code Update

The latest energy code cycle (IECC 2021/ASHRAE 90.1-2019) features changes that will lead to more efficient buildings, saving end users energy and money, but what do you need to know to meet code?

The International Energy Conservation Code (IECC) and the American Society of Heating and Air-Conditioning Engineers (ASHRAE), together with the American National Standards Institute (ANSI) and the Illuminating Engineering Society (IES), published an updated energy code cycle in January 2021: IECC 2021/ASHRAE 90.1-2019.

The new code cycle is the latest edition in a long series of updates spanning many years. In fact, the original ASHRAE standard was published in 1975. Since then, multiple editions have been adopted throughout the United States, with each cycle containing increasingly stringent requirements. Due to the complexity in each new code cycle, contractors often find themselves wondering, “what do I need to do to meet code?” While the answer to this question depends on a variety of factors, such as project location and budget, there are a few basic tips to help builders navigate the latest energy code cycle and get their projects up to code.

The Difference between ASHRAE and IECC

First, ASHRAE is a standard, not a code. IECC is the code that references the ASHRAE standard. Other differences include:

- ASHRAE and IECC have different 3-year cycles.

- IECC follows behind ASHRAE by 2 years. For example, IECC 2012 references ASHRAE 90.1-2010. IECC 2015 references ASHRAE 90.1-2013.

- IECC offers fewer choices than ASHRAE 90.1. For example, ASHRAE offers a semi-heated space option; IECC does not. This means that IECC is ultimately a more stringent code than the ASHRAE standard.

What Is in a Code

There are three major components of an energy code:

- Lighting,

- HVAC, and

- Envelope.

Additionally, there are many elements within the building envelope subject to energy code regulations, including:

- Opaque roof and wall assemblies,

- Windows,

- Skylights,

- Doors,

- Foundation, and

- Floor.

Changes You Should Know: IECC 2021/ASHRAE 90.1-2019

To make things easy, this section compares IECC 2021/ASHRAE 90.1-2019 to the most widely adopted code cycle, which is IECC 2015/ASHRAE 90.1-2013 (’15/’13). Though IECC 2015/ASHRAE 90.1-2013 is not the newest cycle prior to the ’21/’19 update, it is still the most widely adopted across the country. Thus, all comparisons will be made between ’21/’19 and ’15/’13.

One of the larger changes falls under the air barrier category. An air barrier is a material or system of materials designed to reduce uncontrolled air leakage and air infiltration through a building’s thermal envelope (see Image 1). The thermal envelope separates conditioned space and outdoor air. An air barrier can technically be composed of different types of material and/or coatings, such as polyolefin. An air barrier can be placed on the interior side, exterior side, somewhere within assemblies composing the envelope, or any combination thereof.

While air barriers were made mandatory in the IECC 2015/ASHRAE 90.1-2013 code cycle, never before were air barriers required to be verified. That has changed in the latest code cycle, which now requires the continuous air barrier to be verified by a code official, a registered design professional, or an approved agency in accordance with

the following:

- A review of the construction documents and other supporting data shall be conducted to assess compliance with the requirements in Section C402.5.1.

- Inspection of continuous air barrier components and assemblies shall be conducted during construction while the air barrier is still accessible for inspection and repair to verify compliance with the requirements of Sections C402.5.1.3 and C402.5.1.4.

- A final commissioning report shall be provided for inspections completed by the registered design professional or approved agency. The commissioning report shall be provided to the building owner.

Other notable changes from ASHRAE 90.1 2016, International Energy Conservation

Code (IECC) 2018, and the International Building Code (IBC) section 1402.2 include (see Figure 1):

- More stringent air sealing and blower door testing requirements.

- A reduced BTU table for semi-heated spaces. This means that the maximum allowable heat output per climate zone has been reduced, thus making the semi-heated compliance path more difficult to use.

- Mechanical systems updates, updated equipment efficiency requirements, and refinement of energy recovery ventilation requirements.

- A more stringent requirement for lighting systems, such as increased lighting efficiency and decreased lighting power densities requirements.

A requirement that commercial buildings be electric vehicle (EV)-capable or have ready

charging stations.

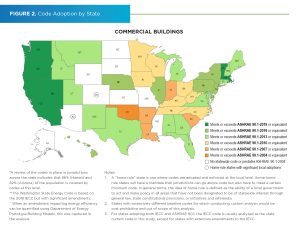

Code Adoption by State

The following states have adopted the newest energy code cycle, IECC 2021/ASHRAE 90.1-2019:

- Massachusetts

- Nevada*

- Oregon

- Vermont

- Washington

*Pursuant to NRS 701.220, the Nevada Governor’s Office of Energy is required to adopt the most recently published version of the IECC on a triennial basis. However, each state municipality has its own building department and may adopt a different code. Currently, the majority have adopted IECC 2018. Visit https://energy.nv.gov/Programs/Building_Energy_Codes/Local_Adoption_Status/ for Nevada’s local code adoption status. See Figure 2 for a summary of code adoption by state (for commercial buildings).

The Biggest Question to Answer in 2023: “What Do I Need to Meet Code?”

As we move toward greater complexity in each code cycle, this longstanding question will only become more common. As simple as the question sounds, it is very difficult to answer. In short, the compliance path I recommend most often is the prescriptive approach. Per the U.S. Department of Energy, the prescriptive approach includes “requirements that either must be met by every building design, or if the requirement is not met, a tradeoff can be made to make up for not meeting that requirement.” In other words, you must meet all U-values of the roof, walls, foundation, and fenestrations. If a tradeoff is indeed needed in the end, the quoted price has covered any changes.

Some other areas of the building envelope I have had to address come from the International Building Code (IBC)—specifically, the structural code. The important section to review is Section 1402.2: Weather Protection, which covers weather-resistive barriers in exterior walls. If the metal building wall panel supplier has not tested its panels per ASTM E331—which is the exemption for having to create a wall cavity designed with flashings and a means for draining water that enters the assembly—compliance can be very difficult.

In order to meet the stricter insulation requirements of the last few code cycles, double-layer systems have become the standard. The two most common include liner systems (sometimes abbreviated “Ls”) and long tab banded systems. Liner systems are typically proprietary and must meet ASHRAE’s requirements in order to be defined as a liner system (Ls). Long tab banded systems are usually non-proprietary and meet the specifications of a filled cavity (Fc) system.

Both systems provide high-R value insulation to help meet stringent energy codes. One key difference is that certain banded liner systems also qualify as OSHA-compliant fall protection systems, whereas most long tab banded systems typically do not offer fall protection. Both options fulfill the metal building insulation U-value code requirements, so the system selected boils down to budget and preference.

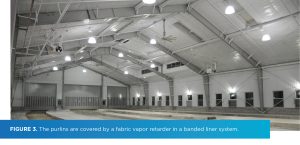

In a banded liner system, large panels of fabric or other vapor-retarder material is supported by banding and installed underneath the purlins. Multiple layers of unfaced and/or faced (air barrier) metal building insulation is installed on top of the supporting fabric and banding filling the cavity. The purlins are covered by the fabric vapor retarder in a banded liner system (see Figure 3).

A long tab banded system is a single- or multi-layer filled cavity system where the first layer is laminated metal building insulation installed parallel and between the purlin space. The long tab vapor retarder is joined or seamed on top of the purlins. A second layer of unfaced insulation may be placed on top of the first layer, perpendicular to the purlins. Banding on the bottom of the purlins provides support. In a long tab banded system, the purlins are left exposed (see Figure 4).

The Bottom Line

The code cycle changes that have either arrived or are coming soon to your state are, without a doubt, challenging to say the least. However, these newest code changes mean more efficient buildings and more innovative solutions that have greater potential to save end users money.