NIA Contractor Members Discuss System Design: JT THORPE (Formerly Thermal Solutions, Inc.)

(Editor’s Note: At the time of the project and publication, this company was Thermal Solutions, Inc., but has since become JT THORPE. The personnel, positions, and project reflect Thermal Solutions, Inc. at that time, however, this article’s title and text have been updated to reflect the company’s current name. Images are from the original publication and therefore show the original name.)

NIA is proud of the professionalism, creativity, and artistry of our Contractor members. To celebrate the craftsmanship of NIA mechanical and industrial insulation contractors, in 2023 we unveiled the first-ever NIA Insulation Project Art Gallery Showcase and Competition. We invited all NIA insulation contractors to submit photographs and a brief description of projects representing their most creative and artistic efforts. At Fall Summit, we posted all the submissions anonymously, and attendees voted for the top three projects in terms of number of parts insulated, aesthetics, difficulty of installation, and well-installed application. As a new regular column, we will profile the projects submitted, focusing this month on the 2nd place winner, JT THORPE (Formerly Thermal Solutions, Inc.). We encourage NIA Contractor members to participate in the 2024 Insulation Project Art Gallery Showcase and Competition, and possibly be featured in future articles.

PROJECT SNAPSHOT

Insulation Contractor:

JT THORPE (Formerly Thermal Solutions, Inc.)

Industry Segment: Food Processing

Type of Plant/Facility: Distillery

Temperature Range: Above-Ambient System

Region: Southeast

System Designed/Application Type: Cellular Glass Covered with Stainless Steel Metal Jacketing (see Table 1 through Table 4 for all product types used).

Project Description and Goals

A large distillery in the Southeast had a new construction/expansion project that involved insulating new mash cookers, stills, and vessels. Goals for the project included achieving energy savings; personnel protection; and process, condensation, and corrosion control.

Challenges

This was a highly complex project that presented challenges on multiple levels: size, scope, complexity, and scheduling, as well as the complications presented by the onset of the Covid-19 pandemic.

The new construction/expansion effectively doubled the size and production capability of the distillery, but the facility continued operation uninterrupted during it. It was a project of massive scale involving all of the trades working together. JT THORPE (Formerly Thermal Solutions, Inc.) Project Foreman Dan Lowry complimented the project managers and the General Contractor, calling them “stellar,” saying he was impressed at how well they handled the safety and scheduling of everyone. Lowry explained the insulation contractors and tradesmen had to keep out of the way of facility staff but also take all the necessary steps to ensure the distillery stayed within code for food production—for example, diligently establishing and maintaining barriers to keep insulation and other construction materials from possible contact with the processes in production.

The project also presented physical challenges that made JT THORPE’s corporate focus on safety paramount to successful completion. Lowry described vessels “6 feet in diameter and 50 feet tall,” adding that because grading on the site did not allow for the use of lifts, “the first hurdle was to get to the job.” Given the height and size of the vessels, “everything had to be done off very large ladders, using beam straps, retractable lanyards, and harnesses tied off above 4 feet.”

Mother Nature kicked in to make things interesting, too. In a project that Lowry estimated was overall 60% outside and 40% inside, weather conditions can be critical. For example, while new construction was underway, a cold snap moved in that threatened

existing outdoor process elements. JT THORPE’s team insulated more than 3,000 feet of piping in the course of 5 days, working in below-zero temperatures to keep production rolling.

And, of course, Covid-19 hit just as the project was slated to begin, which delayed full startup almost a year. Lowry gave General Contractor ABEL Construction Company, Inc. high marks for their coordination of schedule, safety, and workflow involving multiple trades—all impacted by shortages of labor, supply chain issues, and the need to accommodate new, pandemic-related requirements—so that despite starting a year late, the overall construction finished on time. For its part, Lowry credited JT THORPE for being as prepared as possible and having a solid strategy to keep to its schedule. On the production side, John Stevens’ and Managers Jude Malone’s and Tony Kirk’s proactive approach to project management meant that when other companies were scrambling to get materials, JT THORPE’s team already had what they needed to get to work. Lowry noted materials were back-ordered 3 to 6 months, and “you could not buy duct wrap,” but JT THORPE had everything in stock. When Covid restricted the number of people allowed on site, they sent in a limited team to get measurements so they could prefabricate some of the equipment, and they established smaller teams of work crew units to limit possible exposure to the virus.

JT THORPE’s Approach

The expansion project was completed in phases, with the mash cookers built first. Once they were completed, the facility was actually erected around them.

Mash Cookers

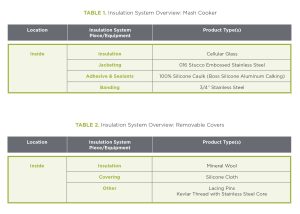

The application includes a high-heat cooker that requires a quick cool-down. JT THORPE utilized a cellular glass application with stainless-steel jacketing. Cellular glass was chosen because of its heat retention, rigidity, self-supporting nature, and the environmental conditions of the facility. In addition to meeting the customer’s goals regarding energy savings, process control, personnel protection, and condensation and corrosion control, the design provides for system longevity, which reduces long-term maintenance costs for the customer. Table 1 offers an overview of the mash cooker

insulation solution.

With a distillery, because even slight fluctuations in temperature can affect viscosity and other factors that make the difference between a smooth bourbon, for example, and a ruined batch that possibly also causes damage to expensive process equipment, mechanical insulation is mission critical. At the same time, the production processes involve equipment that needs to be maintained. Recognizing that removing insulation to give workers access for preventive maintenance often results in damage to the insulation (or worse—insulation destroyed and not replaced), JT THORPE’s proposed covering elements such as flanges and valves with removable insulated blankets to allow easy access and insulation replacement once maintenance was finished. Table 2 lists elements of the removable cover solution.

Thumper

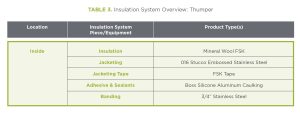

Table 3 lists elements and products used for the thumper.

Additional Tanks and Vessels

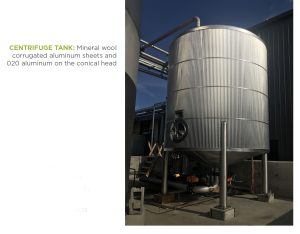

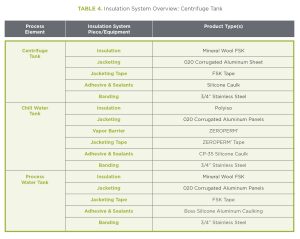

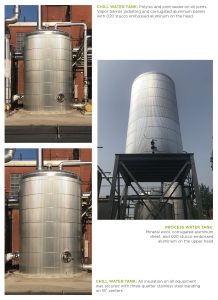

JT THORPE was also responsible for insulating a centrifuge tank, chill water tank, and process water tank. Table 4 details the insulation system components and products used for each.

Project Takeaways

Key takeaways from this project reinforce themes mechanical insulation contractors stress are important with every job.

The Value of Coordination on Design to Meet Customer Objectives

From using ceramic spray on piping to provide thermal control for process performance and facility personnel safety in areas where space was confined to covering equipment such as flanges and valves with removable blankets to facilitate access for preventative maintenance, to changing the original spec from smooth stainless steel to a thicker gauge of embossed metal for improved durability (and appearance, as smooth stainless steel would show scratches that would inevitably result from mechanical and human abuse over time), JT THORPE was able to work with the Project Engineer and customer to identify materials and applications that would best meet project objectives.

Safety

JT THORPE’s corporate culture of safety made a huge difference on this project. For example, in addition to the site challenges, and the added concerns of protecting everyone from a dangerous, pandemic virus, working with stainless steel can be extremely dangerous. The team spent thousands of manhours crafting and installing the stainless steel elements without a single injury. Calling up the image of how easy it is to get a serious cut from just the lid of can of tuna, Lowry said the company’s impressive performance statistic resulted from their commitment to safety. “Every piece of stainless steel had a safety edge. [We made sure there would] never be a sharp edge on any of the stainless steel jacket we installed.” All personnel wore necessary protective equipment without fail, including Kevlar gloves and arm guards.

Precision Installation

The project benefited from having a team with outstanding experience, skills, and training, including a supervisor with more than 19 years of experience and a talented and committed 19-year-old apprentice. As just one example of the complexity of the installation, Lowry explained how “the ceramic coating used starts out very thick—almost like drywall mud—and has to be mixed to a specific consistency.” A large, industrial paint sprayer was used for application, with different tips and nozzle sizes as appropriate. Anything within 8 feet had to be completely covered to protect it against overspray. Two layers were required to ensure thermal retention, for both process efficiency and personnel protection, and each layer needs to be of a precise thickness. Additionally, each layer needed to dry before application of another layer or equipment use.

Due to the number of protrusions, this complex required precise design and application. In every aspect of installation, the project illustrated the exemplary craftsmanship of JT THORPE’s team of insulators.

Customer Focused on Quality, Willing to Invest

Lowry noted, simply properly insulating steam lines pays for itself in a year or less. When you run through all the ways using the appropriate materials and installing them properly saves energy and money—including the human and financial costs of not providing adequate personnel protection, and the cost of process inefficiency or downtime—the benefits are obvious. Still, some projects seek to cut corners, which makes projects with customers who recognize the value and budget the up-front cost for short- and long-term gain so satisfying. This customer was focused on the quality of the project and saw the benefit of insulation. They were very interested in having a system that would last for decades.

A Truly Rewarding Project

Lowry called this project “one of those jobs that’s just perfect for a good mechanical insulator” because it called for a full range of capabilities and experience. “From fabrication to the materials used—polyiso, ceramic, material wool, you name it—we took measurements and cut our own. We got to run the entire gamut of skills.” JT THORPE submitted this project to NIA’s competition because it illustrated the exemplary craftsmanship of the company’s insulators. Lowry said the project’s success truly depended on the outstanding performance of a core team that included Vincent Benningfield, Rodney Dreher, Gary Hahn, Jason Hillerich, and Tyler Langley. Lowry summarized, “It was just a fantastic project. The materials were correct, the installation was solid… things just flowed very well.” The competition was created after this project was concluded. Lowry emphasized that the insulators were not thinking about winning a prize; this was just a normal project for them. When thinking back, he said what really stands out to him was how the entire team worked well together during a difficult time, from the Lead Project Engineer to the General Contractor to all the other trades. Lowry is extremely proud of the work his team accomplished. “We have a core group that are animals when it comes to teamwork… All the guys knew it, too. This was one of those jobs where the project manager more than one time thanked me. Everybody respects what you’re doing for them.”

In the end, that makes this a truly rewarding project for everyone.

NIA congratulates 2023 competition winners:

First Place: Elite Insulation, Inc.

Second Place: JT THORPE/Thermal Solutions, Inc.

Third Place: Argus Contracting, LLC

We thank all the entrants who helped highlight the diversity and creativity of the mechanical insulation industry:

-

DKB, Inc.

-

Gribbins Insulation Company

-

Hudak’s Insulation Inc.

-

I&I

-

Kerco, Inc.

-

Luse Thermal Technologies

-

Performance Contracting, Inc.

-

Taurus Insulation, LLC

-

Texoma Industrial Insulation, Inc.

Watch for future articles with details on other projects submitted.