Data Mining—A Great Tool to Identify Key Safety Focus Areas

It is widely accepted that the most effective way to identify opportunities to reduce employee exposure to safety risks is by performing proactive risk assessments and other audit and assessment activities. It is always better to identify, reduce, and eliminate risks and hazards before an injury occurs. Having said that, we should not discard what has happened in the past. Often, a review of historical injury and incident data reveals trends that will continue to impact the safety of our workers if sustainable controls are not implemented. Known as “data mining,” this approach is used by many experienced safety professionals to identify key safety focus areas.

An important step for the analysis of injury/incident data is determining what inputs should be captured. These can vary greatly, depending on the work performed and the types of risks present in the workplace. At Johns Manville, the incident management database used to capture this data may seem a bit overwhelming for a new safety professional because many inputs are required to be entered. However, this multitude of input data allows for injury/incident trends to be analyzed in countless ways.

Examples of Data and Trend Analyses

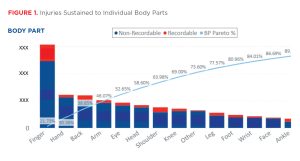

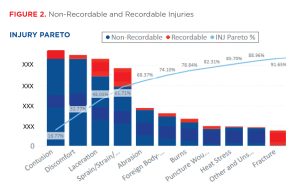

The following figures provide examples of data trend analyses and the conclusions that were drawn from them.

Figure 1 shows that in this organization, the fingers and hands were the most frequent body parts injured. This data led the organization to create a special emphasis program aimed at reducing the number of hand and finger injuries. (The total number of injuries has been removed for confidentiality reasons).

Figure 2 shows a multitude of different injury types. At first sight, it is possible to conclude that no clear pattern stands out. However, a closer look shows that two of the top four injury types are directly related to ergonomic stressors (discomfort and sprain/strain). As a result, the organization moved to perform more ergonomic risk assessments to identify ergonomic improvement opportunities. (Again, the total number of injuries has been removed for confidentiality reasons).

Data analysis also showed that newer employees (less than 1 year of tenure) suffered injuries at a far higher rate than injuries that occurred in the total workforce. This disproportionality led the organization to improve and standardize the employee onboarding process. The data also helped guide how the organization selects trainers from within the tenured group to provide on-the-job training to the newer employees.

Conclusion

Because risk assessments, hazard analyses, and other hazard identification tools are proactive and are performed before an injury or incident occurs, they are the preferred methodology for injury prevention. However, data mining (the review of historical injury and incident data) may reveal injury trends that can also help us to identify key safety focus areas.