Is There a Cure for Corrosion Under Insulation?

Most facility managers, engineers, and maintenance and construction personnel now know that corrosion under insulation (CUI)

exists and, left to its own devices, can cause serious problems and even catastrophic consequences.

It is also widely known that the results of CUI are costly. How costly? That is harder to define. Most studies on the topic

involve all forms of corrosion and their associated costs without providing the individual cost of corrosion related to

insulation.

What is clear, however, is that the cost of corrosion in the United States continues to increase. A study completed in 2001

by a research team of corrosion specialists enlisted by Congress titled, “Corrosion Costs and Preventative Strategies in the

United States” reported the direct cost of corrosion to be $276 billion per year, with that number potentially doubling when

indirect costs are also considered. Compare this to the first study conducted in 1975, which established the benchmark cost

of corrosion at $70 billion. Factoring in inflation, this is actually an improvement if the data are compared to the gross

domestic product, with 3.2 percent for 2001 versus 4.2 percent for the 1975 study.

CUI is typically difficult to identify because it lies hidden under insulation material, often until it becomes a serious

problem. It is also expensive to inspect for or repair since that usually requires inspection by radiography, ultrasonic or

other forms of inspection but in most cases requires the removal of the insulation system. This is especially true if the

removal involves material with asbestos. A study done by ExxonMobile Chemical and presented to the European Federation of

Corrosion in September 2003 indicated that:

-

The highest incidence of leaks in the refining and chemical industries are due to CUI and not to process corrosion;

- Most piping leaks (81 percent) occur in diameters smaller than 4-inch nominal pipe size; and

- Between 40 and 60 percent of piping maintenance costs are related to CUI.

Finally, one of the largest chemical manufacturing companies in the world, E.I. DuPont de Numours and Company, estimates that

the direct cost of CUI repairs and replacements well exceeds $10 million per year, which does not include normal preventative

maintenance costs and indirect costs like loss of production and revenue. This is especially revealing since DuPont is known

internationally as a company with world-class facility engineering, maintenance and workplace safety.

Adding to this problem is the accepted belief that industrial facilities in the United States are aging, being operated and

maintained by fewer personnel, and funded by reduced budgets.

It can therefore safely be determined that CUI remains a large problem for industry, even if it is not clear exactly how big

the problem is today.

For CUI to form there must be two basic ingredients: moisture and warm temperatures. For iron products like carbon steel

piping and equipment, oxygen is also needed. To have chloride stress corrosion (SCC) of 300 series stainless steel, there

also must be the presence of chloride ions. Obviously, oxygen is fairly easy to find, but, maybe surprisingly, so are

chloride ions, which are available in a great number of places from seawater, drinking and process water, and chloride

chemical compounds to roadway de-icing salts. The presence of acids, acid gases, and bases like caustics and salts also can

create and accelerate corrosion.

Additional factors encourage CUI: the environment, insulation design and specifications, installation craftsmanship, and

maintenance. Let’s examine what can be done to reduce the risks.

The Environment

The Cause

Consider the environment as the food source for CUI. It is the first, the largest and the least controllable factor that can

contribute to CUI. However, it is important to remember and understand all the elements of an insulation system’s environment

that contribute to CUI.

Moisture, or water in all of its forms, is the first and most important corrosive element; without it, corrosion cannot occur

to any real degree. Because moisture can take many forms, it can find numerous ways to get under an insulation system.

Rainwater is the most obvious method, but there is also flooding of insulation systems in low-lying areas and water from

pressurized water wash down or local steam leaks. Water also can come from fire protection sprinkler systems, especially

“deluge” type systems that, when activated, spray water from every sprinkler head—literally deluging the area with a

water

spray as bad as or worse than any rainstorm.

The next source of moisture is water vapor penetrating and soaking down the insulation systems operating at or below ambient

temperatures. The final source is ice, normally cold service insulation systems operating below the freezing point. Although

insulated piping and equipment under a layer of ice do not corrode significantly since the temperature limits the available

heat and oxygen (two of the three necessary elements of corrosion), it provides a near ideal corrosion area where the ice is

continually freezing and thawing.

Operating temperature is the next most important element. Above 300 F, most moisture that finds its way into the insulation

system evaporates before it can get to the surface and start corrosion. Below 32 F, because of relatively low energy levels,

corrosion rates are dramatically reduced and the formation of ice limits the amount of oxygen available. However, between 32

F and 300 F is where CUI can happen for carbon steel, and between 140 F and 300 F for 300 series stainless steel. The

“optimum” temperature range for aggressive corrosion on both carbon steel and 300 series stainless steel seems to be between

200 F and 240 F. In this range, there is plenty of heat energy but not enough heat to efficienty evaporate moisture before it contacts the equipment surface.

Chemical exposure is the final major environmental element affecting CUI. Acids and acid gases like chlorine, hydrochloric or

sulfuric acid; strong bases like caustics; and salts are also aggressive corrosive agents and will both cause and accelerate

existing CUI.

The Cure

Since most elements in the environment that contribute to CUI are very difficult or impossible to control, the only hope of a

“cure” lies in properly dealing with the other factors contributing to CUI: design and specification, installation

craftsmanship and maintenance.

Design and Specification

The Cause

Often the original design of the equipment is the start of CUI problems. Piping or manway openings for equipment that are

sized too short to extend past the weather barrier of the insulation system provide an optimal leak area for water, corrosive

chemicals and contaminates to get into the insulation to start corrosion. Facility designs like pipe racks that do not leave

adequate room for insulation to be installed without interfering with the insulated pipe or equipment next to it also provide

a likely spot for future corrosion.

Failure to design and specify a protective coating requirement for carbon and 300 series stainless steel operating in the

temperature ranges likely to cause CUI is frequently a problem. Historically, carbon steel pipe and equipment that were going

to be insulated received no protective coating, in part because the insulation system was looked at as a kind of protective

coating and in part because they were going to operate above 200 F and it was thought that any water would just evaporate.

300 series steel was thought to be corrosion proof when it was first used widely in industry, and protective coatings were

considered unnecessary. Both ideas proved very wrong as illustrated by the following examples:

-

A chemical company in the Texas Gulf Coast area was forced to replace a stainless steel process column when SCC was

discovered during inspection. There was more than $3 million in replacement costs with more than $2 million in lost

revenue.

- An oil refinery in the Northeast was forced to replace an extensive section of uncoated brine feed lines leading to its

boiler feed water treatment plant when leaks revealed extensive CUI damage.

Equipment and piping design problems aside, often the problem lies with the design and specification of the insulation system

itself. In many cases, it is the result of one of the following:

- Using an existing specification without considering all the factors that will affect its performance; or

- Considering insulation material cost factors ahead of performance considerations, ignoring the effects on long-term and

overall cost.

A number of insulation manufactures are making a variety of insulation products and accessories. Among the best reasons for

such a variety is the fact that no single insulation material, shape, size, configuration, etc., will perform well in every

use. This large variety allows the knowledgeable specifier and end user to select the insulation system that will perform

well over a long time and be cost-efficient. However, when knowledgeable decisions about insulation systems are not made,

problems arise, including CUI. The following are examples of design and specification failures.

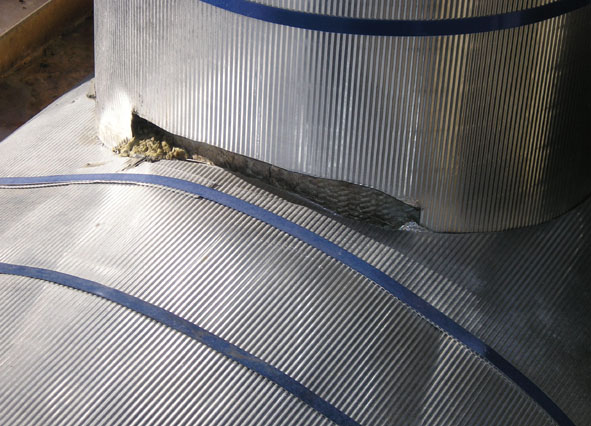

An oil refinery in the Northeast with a boiler feedwater treatment plant whose carbon steel filter vessels operate at

about

230 F had been insulated with a low-density insulation material and an aluminum jacket weather barrier. These filters

require some routine maintenance requiring personnel to access the top of the vessels and the piping and manway access

points. The result was sad but predictable. The aluminum jacketing was deformed and damaged by the repeated trampling and

other work access, allowing water to enter the insulation system every time it rained, soaking the insulation system and

providing a perfect opportunity for CUI (figures 1 and 2). Three of the filters already have been identified with significant

corrosion; two have been extensively rebuilt and one is being considered for replacement. All of this comes at a cost of

hundreds of thousands of dollars for repair.

The same boiler feedwater plant mentioned above had several removable insulation covers installed on many of the feedwater

valves in the unit to help prevent freezing of the water in the lines during the cold winters of the Northeast.

Unfortunately, those removable covers installed on valves oriented horizontally accumulated rainwater inside the covers next

to the carbon steel valve surfaces, especially the flanges. Again, with the operating temperature around 230 F, these valves

ultimately suffered serious CUI problems and had to be replaced. A specification requiring a simple drain hole fabricated

into the removable cover on the bottom side, plus requiring the removable insulation cover to be made a bit longer so it

would overlap the existing permanent insulation system on each side of the valve flanges more completely, would have solved

the problem without the extensive cost and downtime of replacing all those valves.

A water treatment plant along the coast in southern California specified and installed an all service jacketing (ASJ)

on

their insulation system for their low-pressure steam and hot water piping systems. The problem with this specification was

the fact that all of these piping systems were installed in several exposed-top “tunnels” throughout the facility, exposing

the ASJ to sun, rain and wind. Not surprisingly, this resulted in the jacketing quickly deteriorating, soaking the insulation

material and corroding the carbon steel piping (figure 3). Several thousand feet of pipe ultimately had to be

replaced.

The Cure

First, understand the environment the insulation system will perform in. Next, understand the purpose for insulation: energy

conservation, freeze protection, personnel protection, condensation control, etc. Finally, design and specify an insulation

system customized to those unique circumstances to give it the greatest chance of success. As part of a successful design and

specification, be sure to consider the need for and proper type of protective coating for the piping or equipment.

Installation Craftsmanship of Jacketing/Weather Barriers

The Cause

Installation craftsmanship can have a great effect on an insulation system’s performance and life. Little else can undo good

insulation design and specification as much as improper or poor quality installation.

Although a poorly installed insulation system almost always compromises an insulation system’s useful life, performance or

both, it is a critical problem with those insulation systems that operate in the temperature ranges where CUI is a potential

problem (from 32 F to 300 F), cycle in temperatures, or may be shut down for periods of time. A poorly installed insulation

system ultimately lets moisture or corrosive chemicals into the insulation and often to the insulated surface, allowing the

start of CUI. Let’s look at some examples.

Caulking and sealants are the final barrier to moisture intrusion and may be installed improperly in a number of ways. They

may not be installed at all (figure 4) or may be installed incorrectly, either by missing sections or by wiping or smoothing

the sealant bead once it has been installed. Smoothing the sealant is often done to provide a more attractive finished

appearance but results in removing about 80 percent of the sealant material, reducing the life of the sealant and increasing

the chance of a leak.

Jacket materials installed without proper “fit and finish” (figure 5) provide easy water access. Gaps between jacket

components larger than 1/8-inch cannot be successfully sealed with caulking and sealants. Stresses and natural movement

between these parts will cause the sealants to fail prematurely, letting moisture and contaminates into the insulation.

Jacketing or weather barriers can also be installed improperly by not providing a proper rainshed. On vertical sections, this

happens when lower sections of the jacketing material are installed over the top of the upper sections (figure 6). On

horizontal sections, it happens when the lap section is installed close to the top or bottom of piping rather than to the

sides (figure 7). It can also happen when a section of jacketing is wrapped around the insulation such that the upper section

of the jacket horizontal lap is overlapped by the lower section. All of these installation errors allow water into an

insulation system.

Insulation terminations or end caps are other places where jacketing can be installed improperly with dangerous CUI

possibilities. End caps can be and sometimes are omitted entirely, with obvious CUI risks. However, subtler problems can

cause almost as much trouble. End caps installed on vertical lines improperly sealed or without attention to rainshed (figure

8) are almost as bad as having no end cap at all.

Problems with vapor retarders also can encourage moisture contamination of cold service insulation systems. Applied

“mastic”-style vapor retarders installed with inadequate thickness or excessive pinholes allow water vapor to penetrate into

the insulation system almost immediately after it is started up and cooled down to operating temperature. Failure to use a

reinforcing fabric within the applied vapor retarders will allow normal stresses during operation to prematurely crack the

vapor retarder and allow water vapor in. Finally, even the best applied or membrane style vapor retarders immediately can be

ruined when jacketing material is installed using screws as attachments instead of bands. Each screw obviously punctures the

vapor retarder, creating dozens of places for water vapor to leak into the insulation system.

The final installation craftsmanship issue that can lead to CUI is storage of insulation materials. Insulation materials

should always be protected from rain and weather. Insulation materials stored on the ground without any water-resistant

covering simply means the insulation gets installed wet right from the beginning.

The Cure

The clear cure remains:

- Install insulation systems according to specifications;

- Install insulation systems using personnel sufficiently trained to install them correctly; and

- Follow up to ensure the job has been properly done, correcting any problems immediately so CUI problems cannot

start.

Maintenance

The Cause

Finally, if design/specification and install craftsmanship issues do not create CUI problems, maintenance problems can.

Insulation maintenance is sometimes a case of too little, too late. Sealant problems (figure 9) or small holes in the weather

barrier (figure 10) do not get noticed until the insulation has been wet often enough or long enough to cause extensive CUI

problems and possible equipment failure. Sections of insulation removed for normal operations and maintenance do not get

replaced until whole sections of the insulation systems have been soaked or contaminated with corrosive chemicals.

Sometimes it is a case of not looking for the signs early enough or recognizing what the early signs of CUI look like.

The boiler feedwater plant, mentioned earlier in this article, with the extensive damage to its filters did not notice that

the insulation jacketing on top of the filters was extensively damaged, causing corrosion on the side walls of the vessel. As

a result, after the first two filters were stripped and repaired, the insulation systems immediately started to be wet down

again, since the source of the water had not been identified and repaired. It was only discovered after the third filter was

found to be corroded and someone finally inspected the tops of the filters. All the new insulation had to be stripped again

and reinsulated.

A chemical plant in the upper Midwest used 300 series stainless steel piping and equipment in its manufacturing process. It

was insulated to ensure that the chemicals within the line remained liquid (and for process control). During a plant-wide

insulation assessment, someone noticed extensive insulation system damage. The inspector asked the plant engineer if he had

experienced any SCC problems and he had not. This answer mystified the inspector until additional follow-up questions were

answered. It was learned that the plant engineer knew they had plenty of SCC on their stainless equipment, but they had not

had any “problems” because they had not had any equipment failures from the corrosion yet.

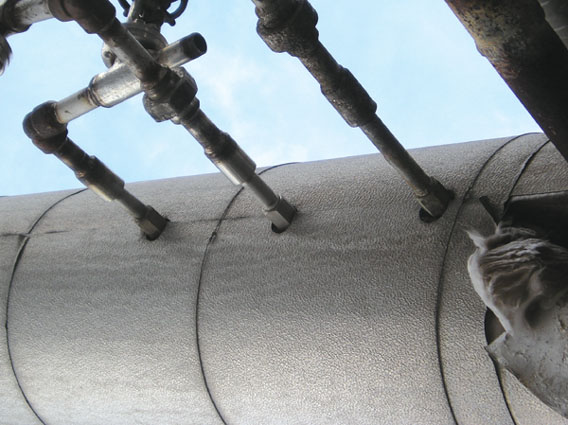

Somewhat curiously, there is a maintenance function that often encourages large contamination and wetting of insulation

systems. The curious part is that it is often caused by personnel and procedures specifically designed to ensure that a plant

site does not suffer from corrosion-related equipment failure. What is the mysterious source? It is cutting sections out of

insulation systems for the purpose of performing equipment integrity inspections and then failing to reseal them either by

patching the insulation or properly installing inspection ports (figure 11).

The Cure

Proper insulation maintenance is a case of “catch it early, fix it early.” Periodically inspect insulation systems to help

identify early failure signs, especially CUI problems. Some staining on jacketing can suggest moisture under the jacket, and

figure 12 shows how some jacket perforations are suggestive of corrosion from the inside of the jacket. Both are telltale

signs that CUI might be happening under the insulation system.

Once problems with insulation systems are identified, they should be repaired as quickly as possible to prevent further

contamination and corrosion, including the resealing of inspection ports.

Summary

We have seen how CUI can be a huge, difficult-to-detect problem that costs millions of dollars. We have also highlighted how

everything from design through maintenance can contribute to CUI. Finally, we discussed how it can be easily prevented

by:

- Accounting for insulation systems during design;

- Designing insulation systems specifically for the environment they will work in;

- Installing the insulation system correctly so it does the job intended, for a long time, with minimal maintenance;

- Learning to recognize the early signs of CUI and insulation maintenance needs; and

- Performing insulation maintenance promptly so that CUI can not get a foothold in a facility.