Supporting Cast

Insulation accessories may include fasteners, adhesives and sealers. These items play a leading role in the performance of an insulation system. These are the subjects that will be discussed in this article.

Mechanical Fasteners

Mechanical fasteners are used to secure insulation to pipe, equipment and ducts. They’re also used to secure the insulation finish on many insulation systems.

Pressure-sensitive polyester film tape is reinforced with continuous glass yarn filaments. This type of tape has been used successfully to secure insulation to pipe. It’s a cost effective method to secure pipe insulation at smaller diameters. Generally, foam, glass fiber and cellular glass insulation up to 12 inches outside diameter can be safely secured to a pipe with a spacing of approximately 9 inches on center. For larger diameters, metal strapping is recommended. Where higher density pipe insulation is installed, such as calcium silicate or perlite silicate, tape may be limited for use to 9 inches outside diameter maximum. Tape is dependent on proper adhesion. Therefore, it should be applied in dry conditions within a temperature range recommended by the tape manufacturer. The tape should be installed with a 50 percent overwrap. Masking tape isn’t recommended for any insulation applications.

There is some concern on outdoor facilities where insulation is secured to austenitic stainless steel pipe with tape. Where the system is operating above 140 degrees fahrenheit, the pipe may be subject to chloride stress corrosion cracking. Such failures have been documented where an insulator has wrapped tape directly to the pipe to prevent the insulation from rotating on the pipe. (The insulation should have been returned to the fabricator because of improper inside dimension.) The adhesive on the tape contained chlorides and, combined with moisture, caused CSCC to the pipe. For those who may be concerned about such an incident, there are reinforced tapes available with a low chloride adhesive.

Matching pressure-sensitive tapes are used to seal butt-joints on factory-applied all service jacketing (ASJ) and foil reinforced kraft (FRK) jacketing. The reinforced tapes work fine on piping but when applied to a flat surface, they tend to fish-mouth (lose adhesion at the edges). The tapes are supplied in rolls and the reinforcing in the tape has a memory. The tape wants to return to its original configuration. For flat surfaces, with a FRK duct insulation finish, it’s recommended that a 2-mil thick pressure-sensitive aluminum foil tape be used. The 4-inch wide tape is recommended, especially on ducts where the corners must be sealed.

Strapping

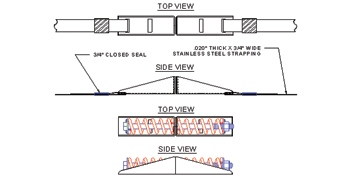

Strapping (banding) provides a positive means of securement on cylindrical pipe, vessels and tanks. Strapping is available in several materials, widths and thickness. The widths range from 3/8 inch to 1-1/4 inch and a thickness of 0.015 inch to 0.025 inch (with 1/2 inch and 3/4 inch being standard with 0.20 thickness).

Most specifications have specified the 1/2 inch wide bands for securing jacketing on insulated pipe and small vessels and equipment. The 1-1/4 inch wide strapping is reserved for the large insulated storage tanks. Galvanized steel strapping is available. This material is popular in European countries where pipe and equipment is jacketed with galvanized steel. It’s not recommended with aluminum jacketing since the zinc can react to the aluminum causing premature corrosion.

For all-around applications, stainless steel is the material of choice. Stainless is corrosive resistant to most environmental conditions and won’t stretch. Strapping stretch has been a particular problem where aluminum bands in the 3/4 inch width or less are applied on vessels and tanks.

Strapping should be applied instead of wire to support the insulation on vessel and equipment heads. This is especially true of bottom heads on vertical equipment. Wire will not handle the necessary load and the twisting of the wire at the outer support rod doesn’t provide a positive tie.

For industrial facilities where chlorides are present, monel strapping is available. It’s known that chloride compounds will attack stainless steel. Monel strapping was installed at several DuPont sites where chlorides were present. However, after several years it was apparent that the monel strapping couldn’t be justified. There was no indication that the existing stainless bands had a significant failure rate and the monel bands cost approximately four times the stainless bands.

Installing stainless strapping over aluminum jacketing shouldn’t be a problem for most installations where the environment is not corrosive. The strapping and jacket are dissimilar metals and corrosion is possible under special conditions.

We have experienced the corrosion of aluminum jacketing, as the sacrificial metal, under the stainless bands on sites close to coastal areas where salts mixed with rain carry inland during inclement weather. This is where acrylic coated aluminum or PVC jacketing is recommended. Although the acrylic coating on the aluminum is only 1 mil thick, it’s sufficient to prevent direct contact of the metals.

Plastic materials such as polypropylene strapping was introduced but had discouraging results on large diameter and hot operating systems. A field test was performed with these straps on a 12-inch insulated steam line with aluminum jacketing. After being exposed to the four seasons of weather and operation of the steam system, the strapping appeared to have relaxed. Plastic strapping may be applied on indoor piping and operating systems at moderate temperatures below 200 degrees F (93 celsius).

Expansion Springs

Expansion springs are used with strapping to provide free movement of insulation jacketing on hot vessels and tanks. Springs may also be applied with strapping on cold tanks where the contraction is a consideration. Expansion springs may also be required on large insulated hot piping. The spring assembly is constructed of stainless steel. The spring size and strength depends on the application.

Vessels less than 10 feet in diameter would normally be finished with smooth, rolled jacketing. This would place the strapping at 10 inches on center and at the circumferential overlap. The springs are available in lengths of 2 and 4 inches. There are single and double spring assemblies. The 2-inch spring assembly should only be considered for large pipe and heat exchangers. Each spring must not be overextended. It’s recommended that a 4-inch spring assembly be initially stretched 1/2 inch. This leaves only 2 inches of stretching to the safe limit. For cold operating tanks, the spring should be stretched to allow the spring to remain in tension when the tank is not operating and at ambient temperature. The "delta T" on cold systems is usually very small compared to hot systems. However, the use of springs should be evaluated.

A general guide is to install a 4-inch spring for every 25 lineal feet of strapping. For a hot insulated tank 10 feet in diameter, each strap requires two 4-inch expansion springs, equally spaced according to the 25 lineal feet rule. A tank 10 feet in diameter, including insulation, constructed of carbon steel and operating 800 degrees F above ambient, will expand approximately 2 inches.

- change of length = ntl/100

- n = coefficient of expansion for 100 degrees F.

- t = change in temperature (delta T)

- l = length in linear feet

- .00065 coefficient of expansion for 100 degrees F.

- 870 – 70 = 800 degrees F delta T

- circumference of the tank and insulation = 31.4 feet

- .00065 x 800 x 31.4 /100 = .163 feet or approximately 2 inches.

Although a single 4-inch spring will expand 2 inches safely, it’s recommended to use two springs equally spaced. Strapping doesn’t always adjust to the expansion, which can prevent one spring from making the complete adjustment on a large diameter tank. The expansion should be distributed with multiple springs spaced equally.

Expansion springs aren’t the same from all manufacturers. Check their literature for maximum allowed extension and loading. Where corrugated sheeting is applied on larger vessels and tanks, the spacing may be 18 inches on center. This application places a greater support load on each spring and strap and therefore, larger banding and stronger springs are required. One available spring assembly is capable of loads of 300 pounds per inch and is designed for use with 1-1/4 inch wide bands.

It’s true that corrugated jacketing has flexibility when the tank expands, but this shouldn’t be a reason to eliminate springs. The amount of expansion and contraction must be calculated to determine the correct number of springs and type.

Screws

Screws have become a popular method of securement. This is the result of incorporating metal jacketing over insulation. The typical screw for the insulation industry is type 410 stainless steel slotted 1/2 inch hex. washer head-shouldered, type AB, ANSI self-drilling, self-tapping in size number 8 by 1/2 inch standard. These screws are available with neoprene washers, which should be considered for outdoor applications.

Screws should be considered where strapping isn’t expedient. For example, screws are commonly used to secure metal gore systems on insulated ells. For good reason, strapping has replaced screws to secure metal jacketing over pipe insulation. The use of light gage aluminum, which is typically used over pipe and small equipment, doesn’t provide much metal for the screw threads to bite. The screws strip the metal and aren’t secured. On any given facility, it’s not unusual to find a third of the screws stripped.

Another concern with the application of screws on metal insulation jacketing is penetrating a vapor retarder finish under the jacket on cold operating systems. Many insulation systems may require both strapping and screws. For example, on large vessels and tanks, strapping is the primary support to the corrugated sheeting. Screws are installed along the vertical overlapping seam of the jacket for additional support. The length of the screw shouldn’t exceed the depth of the corrugation to prevent penetrating the vapor retarder. The depth of the corrugation should be 1/2 inch or greater when applying a 3/8-inch long screw to the crown of the sheeting. This problem can’t be mentioned too many times.

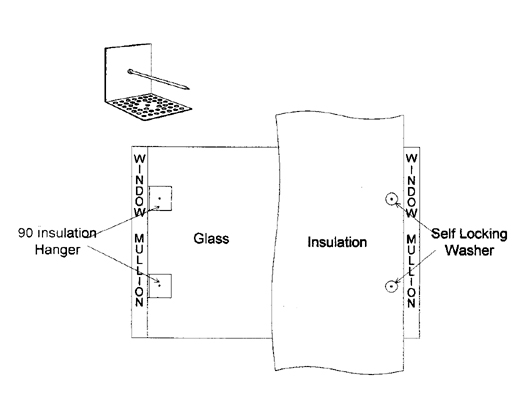

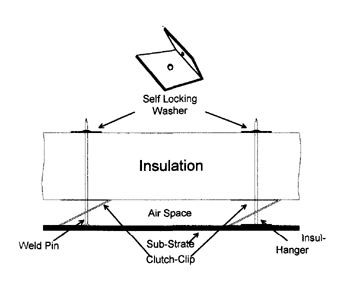

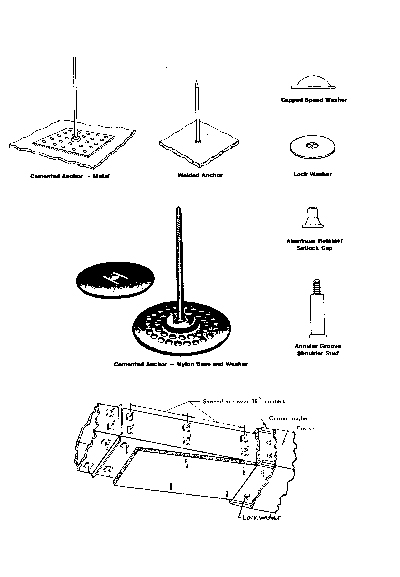

Pins

Pins are used to secure insulation to a metal surface. The surface is usually flat, such as might be found on ducts or breechings. Strapping can’t apply suitable pressure in the center area of a flat surface. The insulation is impaled on the pins and secured to the pin with large compression washers. The pins are located at a maximum spacing of 18 inches on center and no further than 2 inches from any corner. The pins may be secured to the surface with adhesive or welding.

Pins attached by adhesives are spindle anchors. They are available with a metal or nylon plate. A typical spindle anchor with an adhesive base of 2-inch square base plate can safely handle a load of 2 pounds. The spacing of the pins will be dependent on the weight of the insulation. The application of these spindle anchors is limited by temperature. With new adhesives it is possible to install these on equipment operating between minus 40 degrees to 300 degrees F (minus 40 to 149 celsius).

For HVAC ducts or similar equipment operating below ambient temperature, the exposed pin through the vapor retarder must be sealed with the proper vapor retarder mastic or tape.

For applications on equipment operating above 300 degrees F (149 degrees C), weld insulation pins are required. The weld pins are usually specified to the same material as the substrate. Therefore, if the duct is stainless steel then the pin should be stainless. The weld pins are available as a plain 12 or 10 gauge diameter pin or as a cupped-head pin. In the use of the weld pin, or weld nail, many users prefer their weld nails of 1/2 inch longer than material for ease of location and washer installation. The cupped-head pin may be preferred in certain applications because it eliminates the need to install a compression washer, and there’s no excess pin length requiring cutting or bending down. However, you must install the cupped-head pins with the insulation in place and the pin must be the correct length. Manufacturers generally recommend cupped head pins be 1/8 inch longer than the insulating material being installed for proper burn off of the pin and fit of the installed material. Also, when foil faced material is installed using cupped head pins, the underside of the washer must be insulated with a paper liner available pre-installed by most manufacturers. Mineral fiber and glass fiber insulation is normally installed by this method since this material can easily be impaled by the pin and will not create a safety hazard from the welding process.

The standard welding procedure for both type pins is with a capacitor discharge-type stud welding equipment. The immediate area of the weld must be clean (white metal).

Shoulder Studs

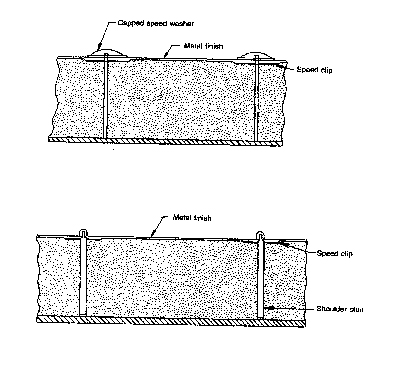

Shoulder studs are installed by welding, similar to the weld pins. They’re available in stainless steel and carbon steel and in various diameters and lengths. The standard size is 5/16 inch diameter with a 0.187 inch diameter by 0.375 inch long annular grooved stem. The spacing is determined by the configuration of the surface more so than the load. These are ideal for application on conical vessel bottoms or oven panels where the metal jacket and the insulation shouldn’t be compressed.

The shoulder studs are welded in place and the insulation is impaled over the studs. The insulation can be temporally secured with speed clips. Place the metal finish over the insulation. Tap the metal over the studs with a rubber mallet to expose the threaded end of the stud. Secure the jacket with setback caps.

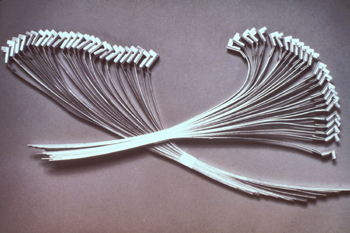

Wire

Soft annealed stainless steel wire is generally available in 18 gauge (0.047 inch diameter) and 16 gauge (0.063 inch diameter). Wire is available in other gauges as well. Galvanized steel wiring is seldom specified in industry today since stainless has maintained a competitive price. Again, galvanized material poses a threat to hot operating stainless equipment and pipe. The zinc can leach from the galvanizing in the presence of moisture onto the stainless and cause corrosion.

Wire is used extensively to support 2-piece rigid pipe insulation such as calcium silicate and perlite silicate. Although, the stainless wire is less costly than the stainless bands, there’s a limit to its strength and therefore shouldn’t be used to support insulation on large piping.

Caution should be exercised in using wire to support glass fiber and mineral wool insulation. When the wire is tightened, it can cut into the insulation. This is also true of foam insulations such as phenolic and polyisocyanurate (PIR).

Adhesives

Adhesives provide support and securement, and are used extensively to secure insulation to itself, to a substrate or perhaps to an outside finish. In all cases the adhesive must be compatible to both surfaces if they are different. Adhesives are also limited by the application and operating temperature exposure.

Some adhesives commonly used in the insulation industry are:

- Fibrous adhesives: These are used to bond thermal insulation to itself or to substrates in high-temperature service, 50 to 800 degrees F (10 to 426 degrees C). It’s sodium silicate based and is non-flammable in wet and dry state. Fibrous adhesives are commonly used on calcium silicate and perlite silicate insulation.

- Water-resistant adhesives: These are used to bond fibrous insulation to metal in cold and warm temperature service of minus 20 to plus 200 degrees F (minus 28 to plus 93 degrees C). It’s a fast-setting rubber based adhesive with low flammability in dry state.

- Anchor adhesives: These are used to bond metal or nylon spindle anchors to metal ducts, masonry walls, concrete or metal ceilings with a service temperature range of minus 40 to plus 300 degrees F (minus 40 degrees to plus 149 degrees C).

- Fire Resistive Adhesives: These are used to bond phenolic, urethane, PIR and other organic based insulation to itself or to metal substrates with a service temperature range of minus 50 to plus 300 degrees F (minus 46 degrees F to plus 149 C). It is available in solvent and water based which may determine low-flammability or non-flammability in a wet or dry state.

- Contact Adhesives (Cements): Contact adhesives provide a high initial bonding strength on contact when applied to both surfaces. This adhesive is used for adhering many types of insulations, vapor retarder finishes and their laps. The solvent based contact adhesive has a service temperature range of minus 30 to plus 275 F (minus 34 to plus 135 C). The water based contact adhesive has a lower service temperature limit. The water based product is recommended for polystyrene foams and certain plastic films.

Water based adhesives have become available for almost all insulation applications in trowel, brush and spray grades. This type adhesive should be considered for use where there may be an open flame, in occupied areas, for food storage facilities where odor could be a concern and finally in jurisdictions with VOC (volatile organic content) regulations.

Insulation Joint Sealants

Joint sealants are used to seal insulation joints on cold operating systems. This application is only suitable with rigid and flexible closed cell insulation, since the purpose of sealing the joints is to prevent moisture vapor migration to the substrate.

A non-setting (non-hardening) sealant is required on rigid closed cell insulation joints to provide continuous sealing when the insulation contracts from temperature changes. The sealant must maintain resilience, will not shrink or crack during thermal cycling. Flexible vapor retarder, solvent free joint sealant is suitable for use with polystyrene and other insulations. This sealant has a service temperature range of minus 20 to plus 300 degrees F (minus 28 to plus 149 C). Non-hardening, solvent-based butyl sealant remains soft and flexible. The service temperature range is minus 100 to plus 300 degrees F (minus 73 to to plus 149 C).

There are two methods of sealing insulation joints. The insulation joints may be sealed at the outside edge. It’s believed that the insulation joints can be butted tighter, with no gaps in the insulation. The second method is to completely coat the butt of the insulation with the sealant and bring the butts tightly together. If the sealant is applied properly, the joint shouldn’t be any more than 1/16 inch apart.

Tests have indicated that the small gap in the insulation will not create a thermal path and the additional non-setting sealant will maintain a sealed joint when movement of the insulation takes place.

A non-setting sealant is not required on flexible closed cell insulation joints. Compressing the insulation at the joints during installation and its flexibility will compensate for any movement. However, the butt joint surfaces must be completely sealed with a contact adhesive. The adhesive is usually supplied by the insulation manufacturer.

What is proposed in this article is only a guide. If the information above conflicts with the manufacturer’s recommendation, follow that of the manufacturer.