A Different Perspective: What to Know About Ceramic Fiber

Ceramic fiber insulation has been around since the late 1950s and can be found in bulk, board, blocks, and blankets of all thicknesses and densities. It was originally made from white clay called Kaolin found in Georgia and the Carolinas. Believe it or not, ceramic fiber insulation got its roots from refractory.

Up to the 1980s, there were boiler manufacturing companies that owned their own refractory divisions to manufacture brick and refractory for their boilers. Early on, while making very dense refractory from the white clay, ceramic engineers discovered that when the clay was heated high enough, it became a liquid and sometimes formed long fibers and small beads called “shot.” The engineers found that by using these long fibers and shot, they could make a high-temperature insulating material for applications up to 3,000°F. These companies saw the need for high-temperature insulation for their boilers, as well as for the steel and foundry industry that manufactured, for example, pulverizer balls, steel casing plates, and drum plates.

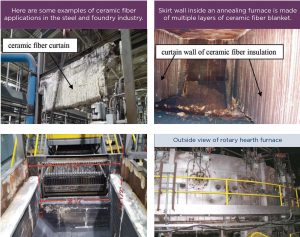

Understandably, high-temperature insulation has more applications in the steel and foundry industry than the power industry. A refractory contractor or distributor may sell as much as twenty times more ceramic fiber insulation materials to their steel and foundry customers as to their power industry customers in a year.

The furnaces and equipment that are lined or insulated with ceramic fiber in the steel and foundry industry have a different insulation requirement than the boilers and equipment in the power industry. It is all about temperature. A boiler burns fuel in order to make steam or heat by extracting or transferring the 2,000°F furnace heat to the tube wall surfaces. Foundries use their 2,000°F furnace heat as part of their manufacturing process to anneal, bake, or melt, depending on their product or products they sell.

Usage of ceramic fiber will depend on the industry using it. The next sections provide examples of how ceramic fiber is used in different industries.

Power Industry

The power industry uses boilers to make steam and heat for generating electricity and not for manufacturing any given product. The use of ceramic fiber is localized and found in different areas of a boiler such as:

- Insulating super heater tubes located inside a penthouse or enclosure that is operating above 850°F. The super heater tubes and headers must be insulated (usually 1” thick) to keep the temperature inside the penthouse below 850°F because the penthouse casing is carbon steel.

- Insulating electric turbines, which generate electricity. They have temperatures around 1,005°F and must be insulated to prevent heat loss.

- Open refractory seal boxes require ceramic fiber to help in the thermal expansion of the seal area. The temperature inside the seal box could reach 2,000°F.

Ceramic fiber insulation is used where refractory seals are impractical due to the thermal expansion of the tubes surrounding a seal area. In photos 1 and 2, ceramic modules were used around super heater loops penetrating boiler water wall tubes.

Ceramic fiber also can be used in lieu of other more conventional types of insulation, such as calcium silicate or mineral wool boards and blankets. Photos 3–6 show typical examples of ceramic fiber being used instead of more conventional types of insulation.

Solar Power Industry

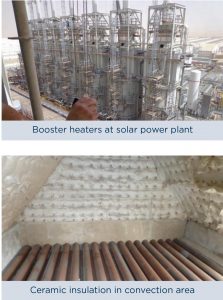

The solar power industry uses heaters as a backup system when there is no sun to generate electricity. The heaters have high operating temperatures of 2,000°F and have wide-spaced tube walls. The tube walls and other exposed areas use ceramic fiber materials to retain the heat.

Ceramic fiber insulation is used over the outside of the radiant walls surrounding the burner area of the booster heater. Booster heaters range in diameters of up to 20 feet or more and can be more than 200 feet high. Typically, these heaters have one large burner located at the bottom, with radiant tubes around and above the burner that creates steam to make electricity using an electric generator (just like a boiler). The amount of ceramic fiber insulation on one heater could surpass all the amounts normally found in a conventional steam-generating boiler.

Steel and Foundry Industry

Foundry furnaces are not lined with tube walls but with brick, refractory, and ceramic fiber products to retain the heat inside the furnace area. This makes foundry furnaces (and ovens) unique, different from steam and power boilers. The steel and foundry industries typically use most of the following in their manufacturing process:

- Coke ovens are used to make coke (pure carbon) as fuel for the furnace.

- Blast furnaces burn or smelt the coke, along with additives of iron ore and limestone, to make molten pig iron formed into large ingots.

- Melting furnaces such as electric arc, cupola, malleable, and open-hearth are used to make pure iron or steel from cold pig iron by extracting all impurities from the pig iron.

- Holding furnaces, such as electric arc or open-hearth, are used to keep the molten iron or steel from the furnaces listed above in a liquid state until it is ready to be formed into ingots or molds (e.g., truck wheels).

The above photos show the inside of a rotary hearth furnace. The charge or pieces to be heated enter at the charge door and are heated as the furnace floor rotates. As the floor rotates, the charge is heated at various heat zones and exits at the discharge door (not shown). The curtain wall is made of many layers of ceramic fiber blanket.

Additional Uses and Characteristics of Ceramic Fiber Products

There are many other uses for ceramic fiber, such as vacuum-formed or die-cut shapes, rope packing for doors, welding blankets, and ceramic rigidizers. Each of these specialty items is unique and can be used regardless of the industry. Ceramic fiber products have high tensile strength characteristics that can withstand physical abuse and vibrations and can be used for most applications up to 2,300°F, particularly useful for insulation material.

Whether in the steel, foundry, or power industries, ceramic fiber insulation is a viable option because:

- K-values are similar to conventional-type insulation;

- It is available in RCF, AES, and low BIO material options;

- Temperature limits of ceramic insulation far exceed normal operating temperatures;

- It can be formed into modules and removable blankets;

- It can be impaled on insulation pins; and

- It does not have binder burnout.

Conclusion

Ceramic fiber insulation has been around for almost 75 years and it is still a viable option for high-temperature applications. It comes in (or can be manufactured into) any shape or form as needed: bulk, strip, blanket, paper, and many others. Its roots are found in the base materials of refractory; and, thanks to some smart engineers, it has helped the power, steel, and foundry industries remain thermally efficient. The more you know about ceramic fiber, the more you become amazed at its versatility.