A Further Understanding of Boiler MACT for Area and Major Sources

This article is a follow-up to the piece that appeared in the

November issue of Insulation Outlook.

The U.S. national elections appeared to have the

expected, definitive effect on the high-profile Industrial Boiler Maximum

Achievable Control Technology (MACT) regulation. As discussed in November’s

article, the regulation’s two subparts have undergone many changes and much

scrutiny over the past few years. Such controversy delayed the passing of a

definitive standard and placed many industrial, commercial, and institutional

facilities in a considerable amount of confusion. This article will clearly

outline the changes, updates, and final adjustments to the Major and Area

Source Boiler MACT standards.

On December 20, 2012, the U.S.

Environmental Protection Agency (EPA) confirmed the particulars for the Clean

Air Act Boiler MACT standards originally published in March 2011. Throughout

2011 and 2012, the EPA released extensive revisions to the specific National

Emission Standards for Hazardous Air Pollutants (NESHAPs). The standards are

divided between 40 CFR Part 63 Subpart JJJJJJ for affected area sources (sources

emitting fewer than 10 and/or 25 tons per year [tpy] of single HAPs and/or

total HAPS, respectively) and 40 CFR Part 63 Subpart DDDDD for major sources

(sources emitting greater than 10 and/or 25 tpy of single HAPs and/or total

HAPS, respectively), as defined by the respective air permits of the facilities.

All of the final adjustments consider facility concerns and employ new

information. Both subparts still work toward preserving public health by

mitigating toxic air pollution while achieving more flexibility for facilities.

The current Boiler MACT standards

divide facilities’ boilers into subcategories defined by boiler type, capacity,

and fuel type. Based on this information, a source must meet emission limits,

work practice standards (including tune-ups and energy assessments), and

operating limits; and/or demonstrate initial/regular compliance. The facility’s

designation as new or existing also will determine if it is subject to the

varying work practice standards and requirements. Below are some critical facts

regarding the final adjustments to the Boiler MACT standards published on

December 20, 2012, including how they may apply, and what impact they could

have, for your facility.

Area Source Requirements

40 CFR Part 63 Subpart JJJJJJ affects facilities

with the potential to emit fewer than 10 tpy of any single HAP and/or fewer

than 25 tpy of combined HAPs affecting sources with boilers defined as

existing, new, or reconstructed. A majority of the boilers affected by this

standard are in the commercial and institutional sectors. It is anticipated that

the final adjustments to the standard will provide relief to some of the

facilities fearful of meeting regulatory requirements and deadlines.

The health benefits have been

researched and examined methodically by the EPA. Approximate

standard-associated reduced exposure to fine particles has a health benefit

value of $210 million to $520 million by the year 2015. The EPA estimates that

the cost for the final standard, incorporating the cost expected to be incurred

by industry, will be roughly $490 million per year. The final modifications

will not raise the standards’ costs but are intended to ultimately decrease the

burden on smaller facilities with boilers.

Only a small fraction of the

boilers currently operating will be affected by the final adjustments made by

this subpart. Based on the final adjustments, 1.3 million of the 1.5 million

boilers at area sources will not be subject because they run on natural gas. Of

the remaining 183,000 boilers, 182,400 require only regular tune-ups and

possibly a one-time energy assessment. The remaining 1 percent of boilers at

area sources will be obliged to meet the more rigorous emissions limits. These

boilers are chiefly coal burning. Due to how little these sources emit, the EPA

is continuing to require work practice/management practice standards, which

include tune-ups for more than 99 percent of area source boilers covered by the

final standards. Less than 1 percent of area source boilers will need to meet

numerical emission limits.

Some of the changes from the

March 2011 regulation that have been made to the final standards will please

both the agencies and the affected sources. A point-by-point list of the

critical changes to the standards as supplied by the EPA in its Technical Fact

Sheet is available at www.epa.gov/airquality/combustion/docs/20121221_boilers_area_recon_fs.pdf,

summarized below.

Extending by 2 years the initial compliance date for existing area

source boilers subject to the tune-up requirement. Now, existing area source

boilers will have until March 21, 2014 to comply with these standards. If

necessary, they may request an additional year. This provides facilities with

2 additional years to meet the requirements.

Revising the deadline for initial notification for existing area source

boilers to no later than January 20, 2014.

Revising provisions for existing dual-fuel fired units that fuel switch

from gas to coal, biomass, or oil, such that they still would be considered

existing sources.

Providing subcategories for seasonally operated boilers and limited-use

boilers.

Requiring tune-ups every 5 years, instead of every 2 years, for certain

area source boilers: seasonally operated units, limited-use units, small

oil-fired units, and units with oxygen trim systems.

Clarifying that temporary boilers and residential boilers are not part

of the source categories being regulated.

Revising particulate matter (PM) emission limit requirements such that

combustion of oil meeting certain sulfur content requirements by new oil-fired

boilers is considered an alternative method of meeting the PM emission

standard, and such units are not required to meet the PM emission limit.

Reducing the fuel sampling and performance testing requirements such

that after demonstration of initial compliance, under certain circumstances,

further fuel sampling for boilers subject to a mercury emission limit, and

further PM performance testing for boilers subject to a PM emission limit, are

not required.

Providing the option of continuous emissions monitoring to demonstrate

continuous compliance with the carbon monoxide (CO) emission limit.

Defining more clearly the scope of the energy assessment and allowing

for more streamlined assessments, including allowing sources already operating

under certain energy management programs to satisfy the assessment requirement.

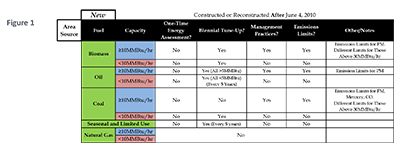

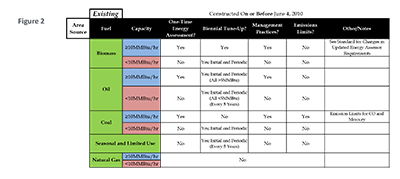

Final adjustments to the rule

have taken many factors into consideration, including concerns raised by the

sources. These rules have made the breakdown of subjectivity more complex than

in the March 2011 standard. To best understand what work practice standards

your facility is subject to, review figures 1 and 2, which provide a basic

overview of what needs to be completed to meet the area source standard for

boilers under the final adjustments. Please note several changes from the

tables published previously.

The final rule for area source

boilers is available on the EPA website.

Major Source Requirements

40 CFR Part 63 Subpart DDDDD affects facilities

with the potential to emit greater than or equal to 10 tpy of any single HAP,

and/or greater than or equal to 25 tpy of combined HAPs. This rule includes

boilers and process heaters burning natural gas, fuel oil, coal, biomass (e.g.,

wood), refinery gas, or other gas to produce steam. Unlike Subpart JJJJJJ,

Subpart DDDDD also includes natural gas/propane/clean fuel boilers. These

requirements contain subcategories with very specific requirements.

Similar to the March 2011 rule, of the roughly 14,000 major source

boilers and process heaters in the United States, 88 percent are required to

conduct annual or biennial tune-ups, and 12 percent are required to meet

emission standards if those standards are not already met. The final adjusted

standards will be considered effective upon their publication in the Federal

Register. As with the area source requirements, existing sources will have 3

years from the publication date to comply with the revised standards. If

needed, an additional year can be requested.

For the major source standard, the annual cost, including industry

costs, to implement the standards is estimated to be between $1.4 and $1.6

billion. Overall, though, the costs to comply per boiler are anticipated to

drop from those associated with the March 2011 standards. This is due to

alterations made to emission limits based on research, which include less

strict obligations for the control of particle pollution on biomass units.

Figure 1 from the EPA standard provides extensive summary costs and benefits

associated with the Major Source Boiler MACT reconsideration for 2015.

Here is a point-by-point list

of the critical changes to the initial March 2011 standards as supplied by the

EPA in its Technical Fact Sheet:

- Adding new subcategories for light and heavy industrial liquids to

reflect design differences in the boilers that burn these fuels. - Adding new emission limits for PM that are different for each biomass

fuel subcategory, to better reflect emissions during real-world operating

conditions. - Adding new emission limits for CO based on newly submitted data that

shows CO emissions from boilers vary greatly. The EPA is setting new limits to

more adequately capture that variability. - Allowing alternative total selective metals emission limits to regulate

metallic air toxins instead of using a PM as a surrogate, thus allowing more

flexibility and decreasing compliance costs for units that emit low levels of

HAP metals. - Replacing numeric dioxin emission limits with work practice standards to

reflect a more robust analysis that shows dioxin emissions are below levels

that can be accurately measured. - Increasing flexibility in compliance monitoring by adding alternative

monitoring approaches for demonstrating continuous compliance with the PM

limit. - Adjusting PM and CO emission limits for units located outside the

Continental United States, to reflect new data and better reflect the unique

operating conditions associated with operating these units. - Continuing to allow units burning clean gases to qualify for work

practice standards instead of numeric emission limits. The EPA is removing the

hydrogen sulfide (H2S) fuel specification from the rule because it

does not provide a direct indication of potential HAP from combustion of

gaseous fuel. Instead, mercury content alone is used to determine clean gas.

To best understand what

standards your major source facility may be subject to, review the major source

standard for boilers under the final adjustments. Again, please note several

changes from the tables published previously. There also are many nuanced

variations based on fuel type and limit specifics that are not included on the

table. The one major change to this subpart is that new boilers are no longer

subject to a one-time energy assessment. All existing boilers and process

heaters at a major source facility, however, still must conduct a one-time

energy assessment for compliance. Please review the actual regulation for

specifics (see www.epa.gov/airquality/combustion/docs/20121221_boilers_major.pdf).

There are many intricacies to

these regulations, and the final adjustments-particularly for the major source

standard-are far too detailed to examine here. Further reading is recommended.

Sources

for Further Reading:

- National Emission Standards for

Hazardous Air Pollutants for Major Sources: Industrial, Commercial, and

Institutional Boilers and Process Heaters (www.epa.gov/airquality/combustion/docs/20121221_boilers_major.pdf) - National Emission Standards for

Hazardous Air Pollutants for Area Sources: Industrial, Commercial, and

Institutional Boilers (www.epa.gov/airquality/combustion/docs/20121221_neshap_ici_boilers_fin.pdf) - EPA’s Air Toxics Standards Major and

Area Source Boilers and Certain Incinerators Technical Overview: Adjustments

from March 2011 Final Standards (www.epa.gov/airquality/combustion/docs/20121221_tech_overview_boiler_ciswi_fs.pdf)