Aeroflex USA- Corrosion Under Insulation (CUI)

Aeroflex USA

www.aeroflexusa.com

Contact:

technicalsupport@aeroflexusa.com

One of the most common and costly threats to industrial piping systems is a phenomenon known as CUI. Corrosion is essentially the deterioration of metals (e.g., cast-iron pipe) due to a reaction with their environment. According to the Association for Materials Protection and Performance (AMPP), corrosion is one of the costliest issues to the global construction economy.

Corrosion under pipe insulation occurs when water vapor (moisture) penetrates the insulation system and makes its way to the metallic pipe surface. If the pipe has not been properly cleaned to remove corrosion accelerators such as dust, dirt, grease, or oil, these substances can accelerate the corrosion process on the pipe surface when they encounter moisture. Once moisture is present beneath pipe insulation, it effectively gets trapped and is a constant source of deterioration.

Although corrosion is a natural process, it can be controlled. Untreated steel pipes for below-ambient operating temperatures, such as refrigeration and chilled water, are often treated with a rust inhibitor or primer. Prior to the application of mechanical insulation, the pipe surface should be cleaned to remove any existing debris. Depending on the substance, common cleaning agents include water and denatured alcohol for oily residues.

A fundamental factor to understand is that water vapor in the environment is naturally attracted to colder surfaces (pipes). This is known as vapor drive. The keys to protecting an insulated pipe are to (1) choose the correct insulation thickness, and (2) completely seal the pipe insulation system to prevent water vapor from penetrating through gaps or openings such as longitudinal seams, butt joints, and termination points.

Accurate pipe insulation thicknesses by project can be determined with industry calculators, such as 3E Plus® (www.3eplus.org) and the Mechanical Insulation Design Guide (www.insulation.org/ design guide), which factor in insulation type, pipe type, pipe size, operating temperature, average ambient temperature, average relative humidity, jacket type, and wind speed.

It is important to note that national energy codes, such as ASHRAE 90.1 and the International Energy Conservation Code® (IECC), specify minimum insulation thicknesses. Demanding operating environments typically require thicker insulation. Under-insulated pipes are unable to control condensation and vapor drive, leading to CUI and eventual failure.

The other critical component to controlling CUI is the proper installation of the pipe insulation system. Vapor stops should be installed a minimum of every 18 linear feet; and all longitudinal seams, butt joints, and termination points must be glued with the insulation manufacturer’s recommended adhesive both for adhesion and to create a vapor seal.

Pipe bends, intersections, and fittings—such as valves, flanges, couplings, and pipe hangers—also must be insulated and vapor sealed. Applying tape alone over unglued seams, or using zip ties, is never recommended. These approaches are common causes of failure.

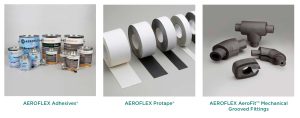

Aeroflex USA’s AEROFLEX® brand of EPDM closed-cell, flexible elastomeric foam pipe insulation is nonpolar (repels moisture at the molecular level) and offers a low thermal conductivity, a closed-cell structure, and built-in vapor retarder that efficiently controls condensation and vapor drive for most applications. In severe operating environments, a supplemental vapor retarder (jacket or coating) may be necessary.

In addition to AEROFLEX EPDM™ insulation tubes (standard and self-seal), sheets, rolls, and AeroFit™ fitting covers, turn-key system accessories include Aerofix® zero-perm insulated pipe supports, Aeroflex adhesives (standard and low-VOC formulas), Protape® zero-perm EPDM tape, and Aerocoat™ (premium and low-VOC formulas) UV protective coatings, all of which offer single-source responsibility.