Aspen Aerogels

Aspen Aerogels

www.aerogel.com

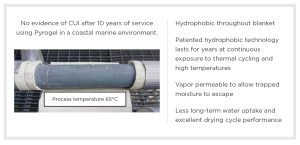

Pyrogel® and Cryogel® flexible blanket insulation solutions have transformed the way refining, petrochemical, and liquefied natural gas (LNG) facilities think about insulation. These insulation solutions deliver exceptional thermal performance to both optimize process yields and protect critical process assets. The patented hydrophobic design drastically minimizes water uptake to maximize defense against the costly and damaging effects of corrosion under insulation (CUI).

Water is the enemy of industrial insulation. Unfortunately, rainfall, humidity, and exposure to ocean air are unavoidable for most refining, petrochemical, and LNG facilities. The risk of CUI increases with the amount of time an asset is in contact with moisture. By keeping assets drier longer, Pyrogel and Cryogel insulation reduce exposure to the harmful effects of CUI. Rather than sit above an asset, Pyrogel and Cryogel insulation conform to surfaces to ensure close contact with the asset they cover. This significantly reduces the space for water retention between the insulation and the asset itself.

Aspen Aerogels® distributes high-performance aerogels evenly throughout Pyrogel and Cryogel flexible insulation blankets. This patented design creates a uniquely hydrophobic composite to repel water and maximize protection against CUI.

Exceptional thermal performance of Pyrogel and Cryogel allows for a significant reduction in the material thickness of insulation required. The thinner profile results in less surface area exposed to the elements, further reducing the risk of moisture affecting the underlying surface.

Eliminating moisture against metal is the first line of defense in any CUI protection strategy. Corrosion inhibitors can be a useful backup. Pyrogel and Cryogel insulation blankets are infused with corrosion inhibitors to buffer any water entering the system to a pH > 7 to further protect against damaging CUI.

During maintenance and turnaround events, tool strikes and footfalls can damage thermal insulation and the protective weather jacketing that is the first line of defense against bulk water ingress. This can result in trapped water and damaging CUI. Pyrogel and Cryogel insulation is durable enough to withstand this common abuse and protect critical processes and assets.

Weather-Insensitive Installation. Pyrogel and Cryogel insulation help support a fast return to service. Projects have a lower risk of delay when teams can continue installation work in wet conditions. Facilities have even restarted operations before the outer jacketing was installed.

Passive Fire Protection. Pyrogel XTF insulation provides an exceptional combination of thermal performance, defense against CUI, and passive fire protection. Corrosion under fireproofing (CUF) often occurs between the assets and fireproofing coatings or cementitious materials. Coatings are not used with the Pyrogel XTF insulation, avoiding a potential avenue for damaging CUF.

Pyrogel and Cryogel flexible blanket insulation provide an excellent solution to both optimize process yields and maintain asset integrity. Facilities no longer have to choose between protection and performance.