Commercial Building Code Compliance: A Look at the Evolution of Energy Codes and Commercial Building Envelopes

The International Energy Conservation Code (IECC) and ASHRAE 90.1 are internationally recognized codes and standards used in the United States for building energy efficiency. Much like a vocabulary drill, we often hear the terms IECC and ASHRAE 90.1 discussed at industry meetings and see them written throughout the literature, but what do these designations actually mean? Furthermore, what are the implications of the latest IECC and ASHRAE 90.1 code cycle for future commercial building projects? What do you really need to know to ensure a project meets the newest envelope code requirements in your region? Before delving into specific building envelope updates, it is important to review the basics.

Differences between ASHRAE and IECC

First, both ASHRAE 90.1 and IECC establish minimum requirements for energy efficiency of buildings. Note that ASHRAE 90.1 is a standard of energy efficiency, not a code agency. IECC is a model energy code that references the ASHRAE Standard 90.1. Both ASHRAE 90.1 and IECC follow 3-year cycles, with IECC cycling 2 years behind ASHRAE 90.1. For example, IECC 2018 references ASHRAE 90.1-2016. IECC adopts the latest ASHRAE standard, plus any addenda and new data. The IECC also increases efficiencies in certain areas, which means that in some cases, the IECC can be more stringent than the ASHRAE standard. Both include heating, ventilation, lighting, water systems, and the building envelope for residential and commercial buildings.

This article focuses on the commercial building envelope requirements in the IECC 2018 and ASHRAE 90.1-2016 code cycle. In terms of specific updates, lighting and mechanicals have many changes and mandatory provisions that can be found in the published versions of both IECC and ASHRAE 90.1. IECC references ASHRAE as an alternative path in section C401.2 (Application). This allows a designer to use the ASHRAE standard in its entirety for compliance. If the ASHRAE standard is used, all envelope, lighting, and mechanicals would follow the ASHRAE standard in full; and any requirements within IECC shall not be used. The opposite is true if a designer chooses IECC. Because of this, understanding the requirements of both the ASHRAE standard and the IECC is paramount.

Compliance

Once a compliance path is determined (i.e., selection of the IECC or the ASHRAE standard), the first choice a designer must make is the building envelope. Both paths have climate zone requirements specific to each zone. Construction types also have specific requirements. For roofs, the choices include the following: insulation entirely above deck, metal buildings, attic, or other.

Wall construction types include the following: mass, metal building, steel frames, wood framed, and other. Floors, fenestrations, and daylighting are also all parts of the envelope; and each has specific requirements.

In regard to the IECC 2018 code and ASHRAE Standard 90.1-2016, compliance is stringent; and both have in-place performance levels that have evolved over the 3-year cycles. IECC and ASHRAE both have 3 basic paths to compliance:

- Prescriptive method,

- Envelope trade-off, and

- Energy cost budget method.

The language is a bit different between the ASHRAE standard and the IECC, but the approach is similar.

Prescriptive method is just that; it entails meeting every U-value, R-value, and any other in-place performance requirements of any envelope assembly and component.

Envelope trade-off is typically demonstrated through COMcheck™, the U.S. Department of Energy’s (DOE’s) compliance software, which you can download for free at energycodes.gov). This option allows a designer to add performance in some areas that can serve as trade-offs for lesser performing areas. For example, you can add roof insulation to trade off wall insulation or door and window U-values. The roof is typically the largest area of a building, and quite economical to achieve performance requirements, thus making the envelope trade-off approach a desirable option for many builders. It is important to remember that IECC and ASHRAE have different trade-off methodologies.

The energy cost budget method is quite involved and can be demonstrated through OpenStudio®, DOE 2, Building Loads Analysis and System Thermodynamics (BLAST), and EnergyPlus™ software. This approach requires all inputs for lighting, mechanicals, envelope, and many other data points. The final result of the energy cost budget method is to demonstrate compliance through reduced energy overall.

Mandatory Provisions

Mandatory provisions also evolved in the IECC 2018/ASHRAE 90.1-2016 cycle, with daylighting and air barriers receiving notable mentions. Most designers have been surprised by the language and requirements surrounding daylighting. Regardless of the path choices noted above, mandatory requirements must be met.

Both ASHRAE and IECC have implemented daylighting requirements in their standards/codes as mandatory. The requirements range from advanced lighting controls, limited amounts of lighting density power consumption, and mandatory 3% skylight inclusion on roof surfaces.

Designers may utilize a range of options to satisfy the daylighting requirement. Generally, a mixture of skylights and/or vertical fenestration can be used. There are varying quantities, depending on the project’s climate zone. Another

factor that may impact the properties of the skylights and vertical fenestration is lighting controls. With the addition of lighting controls, increased solar heat gain coefficient (SHGC) and U-factors may be applied to the fenestration as a part

of the overall design.

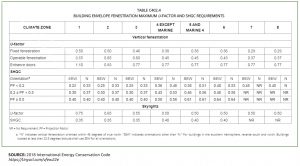

Table C402.4 (from the IECC) indicates the skylight requirements for SHGC, ranging from .35 in climate zone 1 to .40 in climate zone 6. If the area covered by skylights is also in a “daylight responsive lighting control zone” within the building, C402.4.3.1 allows for the skylights to be further reduced to an SHGC of .60. Section 5.5.4.3 and 5.5.4.4 of ASHRAE 2016 further details the SHGC design criteria for daylighting materials.

There are very limited exemptions from the daylighting requirements in either IECC 2018 or ASHRAE 90.1-2016. ASHRAE 90.1-2016 requires daylighting, at reduced value, for semi-heated structures, too.

Air barriers are another major design consideration for code compliance. Though air barrier nomenclature has been included in the code literature as far back as IECC 2012 and ASHRAE 90.1-2010, much confusion surrounding air barrier requirements exists today. Section C402.5 (Air Leakage—Thermal Envelope) of IECC 2018 says it all: mandatory. In other words, air barriers are mandatory in the thermal envelope.

As insulation cavity thicknesses increase with code advancements, the location of the dew point is slowly migrating to within the cavity, instead of somewhere on the surface of the insulation facing, particularly for pre-engineered metal buildings. Air barriers greatly control the rate at which air and moisture migration occur though the insulation cavity.

Air barriers must be contained within the thermal envelope and can be installed on the interior, exterior surface, within the assembly, or any combination thereof. It is critical for air barriers to be continuous for all assemblies and across all joints in the assemblies.

An air barrier design can be based upon a material approach, such as the assemblies listed in section C402.5.1.2.1 of IECC 2018 or the assemblies referenced in ASHRAE 90.1-2016 5.4.3. ASHRAE 90.1-2016 does exempt semi-heated spaces in climate zones 0 through 6, and single wythe concrete masonry buildings in climate zone 2B, from the mandatory air barrier requirement. IECC 2018 has no such exemptions for air barriers, with the exception of low energy buildings outlined in C402.1.1.

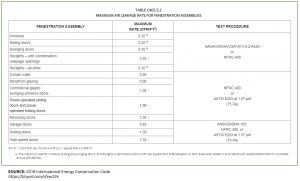

Air barriers also can be verified/certified by means of mechanical testing, such as a blower door test. This compliance option tests air leakage of the entire building as a whole. Typically, a blower door is mounted to the frame of a walk-through door and is used to pull the air out of the building to lower the air pressure indoors. Then, the higher air pressure from outside enters the building through all unsealed openings. The differential is used to calculate the air infiltration rate of the building.

A blower door test is not meant to exempt the design from any construction method. A key consideration of blower door testing includes the fact that, once selected, you cannot opt-out and elect to undergo materials and assembly testing later. If a building fails the blower door test, all repairs must be made until it passes.

IECC mandatory air barrier and thermal provisions also include the fenestration Table C402.5.2.

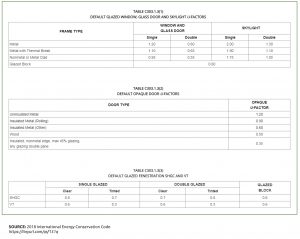

Combined with the fenestration U-factor/SHGC requirements in Table C402.4, achieving full compliance can be difficult if the products do not conform to the tables, as outlined in IECC section C303.1.3 (see below).

If using the prescriptive method or trade-off approach, and labeled fenestrations cannot be provided, the code requires the default values shown in Table C303.1.3(1). Used in the trade-off approach, these values are very difficult to pass the overall envelope. The prescriptive approach does not allow the default values, and therefore must be labeled per code section C303.1.3.

Energy Code Resources

The resources most commonly used for energy code updates include the DOE, the Building Codes

Assistance Project, and the International CodeCouncil (ICC). For the code reference guides,visit ashrae.org and iccsafe.org.

Final Thoughts

In looking ahead at future cycles, no major changes are expected in the actual thermal envelope for commercial buildings. The mandatory provisions are the future cycle and will require actual blower door testing for air tightness. There are exemptions, but they are very limited. The primary reason for these provisions is simple: energy savings. When a new building is constructed with the thermal envelope requirements, it is not actually efficient if the building leaks air and there is no natural light to offset energy consumption with lighting and mechanicals.

Other options have been receiving attention lately that go beyond the codes outlined here, such as stretch codes and envelope commissioning. Stretch codes are current in some states, and each town, city, or jurisdiction would typically require and enforce compliance over the actual state code. These codes are generally written about 10% more energy efficient than the state code. Future stretch code increases are projected to be around 20% to 40%. Envelope commissioning options have several protocols and certification requirements during construction and through the completed design process. Once achieved, these buildings are certified to operate at a fixed cost on energy savings. The final goal is Net Zero for all buildings. Currently, residential and commercial buildings account for 40% of energy use in the United States (source: ase.org). Based on the overall state adoption of the new codes, the projected energy and carbon emissions savings are extensive, and carry the potential for a major impact on the future U.S. building landscape.

In summary, commercial energy codes have evolved quite a bit from their initial adoption years ago, and the landscape has become increasinglycomplex. The most recent code cycles carry more stringent building envelope performance requirements, which, ultimately, propel new innovationsand lead to more energy-efficient buildings.

Copyright statement

This article was published in the January 2020 issue of Insulation Outlook magazine. Copyright © 2020 National Insulation Association. All rights reserved. The contents of this website and Insulation Outlook magazine may not be reproduced in any means, in whole or in part, without the prior written permission of the publisher and NIA. Any unauthorized duplication is strictly prohibited and would violate NIA’s copyright and may violate other copyright agreements that NIA has with authors and partners. Contact publisher@insulation.org to reprint or reproduce this content.

Disclaimer: Unless specifically noted at the beginning of the article, the content, calculations, and opinions expressed by the author(s) of any article in Insulation Outlook are those of the author(s) and do not necessarily reflect the views of NIA. The appearance of an article, advertisement, and/or product or service information in Insulation Outlook does not constitute an endorsement of such products or services by NIA. Every effort will be made to avoid the use or mention of specific product brand names in featured magazine articles.