Energy Appraisals: Invest in Efficiency

In this tough economy, who doesn’t want to reduce their energy bill,

especially if the payback period is short and the return on investment large? Across the country, nearly 800 Certified Insulation Energy Appraisers are surveying facilities and calculating how much energy and greenhouse gas emissions customers could save by repairing, replacing, or upgrading their mechanical insulation. Following are two examples of how the Insulation Energy Appraisal Program (IEAP) benefits everyone involved.

Appraisal Adds to Paper Mill’s Bottom Line

by Mark Reed

A paper mill in Central Maine was looking for ways to stay competitive in this tough economy by maintaining the same production while reducing energy costs. A mill-wide energy survey had recently identified the steam system as a source of energy-saving opportunities.

While visiting the mill, Zampell’s team noticed bare steam and condensate piping going to unit heaters and realized that adding mechanical insulation to the piping could achieve significant energy savings. The team discussed their ideas with the mill’s energy manager, and he agreed to look at the survey results. He indicated that if the return on investment (ROI) fell within 1-2 years, he would be able to go ahead with the insulation project. As a Certified Insulation Energy Appraiser with Zampell Companies, I met with the mill’s energy manager to determine the appraisal’s scope: steam and condensate piping to the plant’s unit heaters.

After gathering the needed process and cost data and measuring the piping, I used the 3E Plus® software to quantify potential improvements in energy savings, greenhouse gas emissions, and overall cost savings. The 3E Plus program is designed to calculate the thermal performance of both insulated and uninsulated piping, ducts, and equipment; translate Btu losses into actual dollars; and calculate greenhouse gas emissions and reductions. All appraisers receive training in the use of 3E Plus as part of the National Insulation Association’s (NIA’s) Insulation Energy Appraisal Program (IEAP) certification process.

My appraisal report documented:

- Energy costs and Btu losses with existing steam and condensate system insulation

- Potential fuel cost savings and Btu savings with an insulation upgrade

- Potential environmental impact of reduced greenhouse gas emissions from the increased energy savings and reduced fuel consumption.

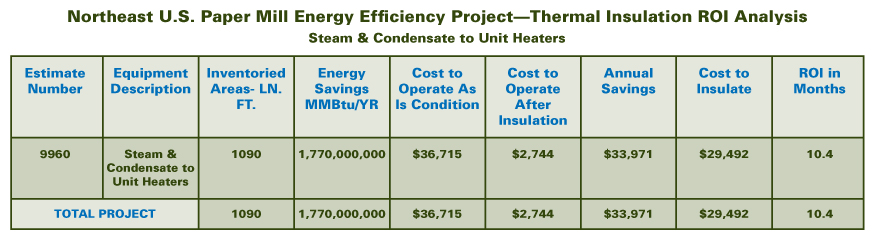

I then met with the mill’s energy manager to review the insulation option and payback scenarios. The survey demonstrated significant savings, as highlighted in the simple ROI summary in Figure 1.

The IEAP survey quantified the energy and cost savings, as well as presenting a payback scenario that exceeded the energy manager’s criteria. He was surprised that the savings were so significant, since the unit heaters only run for 7 months of the year. He said that while he knew insulation was important, it was always hard to put a cost on it. He added that being able to quantify the savings so they can be understood by the operators as well as the accountant is a big help in this economy.

What started as a routine visit to a client and noticing some bare steam piping ended with the Zampell team using the tools and training from NIA’s IEAP to create a win/win scenario for their customer: reduced steam load and significant cost savings.

Appraisal Shows Hospital that Insulation Pays Off

By Peter Gauchel

L&C Insulation, Inc., embarked on a project with Gundersen Lutheran Hospital to save energy in September 2010. The hospital’s energy engineer, Corey Zarecki, was in charge of energy savings throughout the hospital campus and had implemented projects such as installing new steam traps throughout the hospital and building an electric generating plant fueled by gas discharge from the local brewery.

L&C Insulation proposed an energy appraisal throughout the Gundersen Lutheran campus addressing all uninsulated systems with operating temperatures above 140°F, including steam, steam condensate, and heating hot water systems. The steam items included uninsulated traps, strainers, unions, valves, piping, and the steam boiler bodies. Pipe sizes ranged from 4 in. to ½ in., with the majority in the 1 in. to ¾ in. range. The heating hot water items included uninsulated valves, unions, strainers, and pump bodies, with the pipe sizes for these items ranging from 6 in. to ¾ in.

The survey of the uninsulated items covered approximately 30 mechanical rooms of various sizes in five buildings and took several weeks to accomplish. Once the survey was complete, the data was put into the 3E Plus® software, which produced some remarkable savings.

Each building surveyed had an individual appraisal on the items for that building. All appraisals were then compiled, resulting in $48,727 in savings per year.

L&C Insulation then created a proposal to insulate all the identified items with fiberglass pipe insulation for the piping and custom-made removable reusable insulation blankets for all the valves, traps, unions, strainers, pump bodies, and bodies of the boilers. This project was estimated to have a 3.25 year payback.

This payback was acceptable to the hospital but was longer than many other paybacks for insulation projects due to the large number of small traps, unions, and strainers being addressed. Insulating small items is usually not as cost efficient as insulating larger items—e.g., 4 in. and larger valves, strainers, etc.—due to the labor required.

Once all the steam items were analyzed, the small steam items (2 in. and smaller) resulted in a payback of approximately 4.68 years, while the larger steam items (3 in. and larger) resulted in a payback of 11 months. Insulating preinsulated side walls on the steam boilers, which had a surface temperature of 150°F, was also considered and resulted in an average payback of 3.3 years. (The boiler manufacturer explained that insulating the boiler ends would risk warping the boiler doors, so that was not considered.) The heating hot water boilers had a surface temperature of 130°F, and insulating over the factory-insulated boiler sidewalls resulted in a 6.7-year payback.

Insulating all the boilers combined resulted in a 4.77-year payback. When these numbers were put into the Mechanical Insulation Design Guide Financial Calculator, they resulted in a 23.4 percent rate of return over a 20-year period.

With these results, funding was secured and the projects were completed in a 3-month period through the winter. By investing in this project, the hospital will realize a 33.7 percent return on their original investment over a 20-year period. Zarecki said that a 33.7 percent return on investment was something they could not produce anywhere else in the facility.

How You Can Benefit Too

If you’re looking to reduce your energy bill, find a Certified Insulation Energy Appraiser near you at www.insulation.org/training/ieap/appraisers.cfm. If you’re an insulation contractor who wants to expand the services you offer your customers, find out how to become certified at www.insulation.org/training/ieap. In addition to attending an NIA-sponsored course, companies can sponsor IEAP training courses in-house. Contact Julie Cupp at jcupp@insulation.org or 703-464-6422, ext. 114, for more information.