Exploring Insulation Materials: Granular Insulations

Calcium Silicate

Calcium Silicate thermal

insulation is defined by ASTM as insulation composed principally of hydrous

calcium silicate, and which usually contains reinforcing fibers.

Calcium Silicate Block

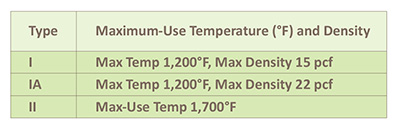

and Pipe Insulation are covered in ASTM C533. The standard contains three

types, classified primarily by maximum-use temperature and density.

The standard limits

the operating temperature between 80° and 1,700°F.

Calcium Silicate

Insulation Products

Calcium Silicate pipe

insulation is supplied as hollow cylinder shapes, split in half lengthwise, or

as curved segments. Pipe insulation sections typically are supplied in lengths

of 36″ and are available in sizes to fit most standard pipe sizes. Available

thicknesses range from 1″ to 3″ (in one layer). Thicker insulation is supplied

as nested sections.

Calcium Silicate

block insulation is supplied as flat sections in lengths of 36″; widths of 6″,

12″, and 18″; and thickness from 1″ to 4″. Grooved block is available for

fitting block to large-diameter curved surfaces.

Special shapes, such

as valve or fitting insulation, can be fabricated from standard sections.

Calcium Silicate is

normally finished with a metal or fabric jacket for appearance and weather

protection.

The specified

maximum thermal conductivity for Type I is 0.41 Btu-in/(h?ft²?°F) at a mean

temperature of 100°F. The specified maximum thermal conductivity for Types IA

and Type II is 0.50 Btu-in/(h?ft²?°F) at a mean temperature of 100°F.

The standard also

contains requirements for flexural (bending) strength, compressive strength,

linear shrinkage, surface-burning characteristics, and maximum moisture content

as shipped.

Typical applications

include piping and equipment operating at temperatures above 250°F, tanks,

vessels, heat exchangers, steam piping, valve and fitting insulation,

boilers, vents, and exhaust ducts.