Improvements in Water Vapor Retarder Jacketing for Use Over Mechanical Insulation

In the last decade, there have been several

developments in water vapor retarder jacketing designed for use over insulated

pipes, ducts, and equipment. In most cases, these developments have improved

jacketing by providing lower permeance to water vapor, tighter sealing of

joints, greater strength, and improved appearance. While there have been some

improvements on new types of indoor-only jacketing, there is also a whole new

category of jacketing designed for outdoor use.

Terminology

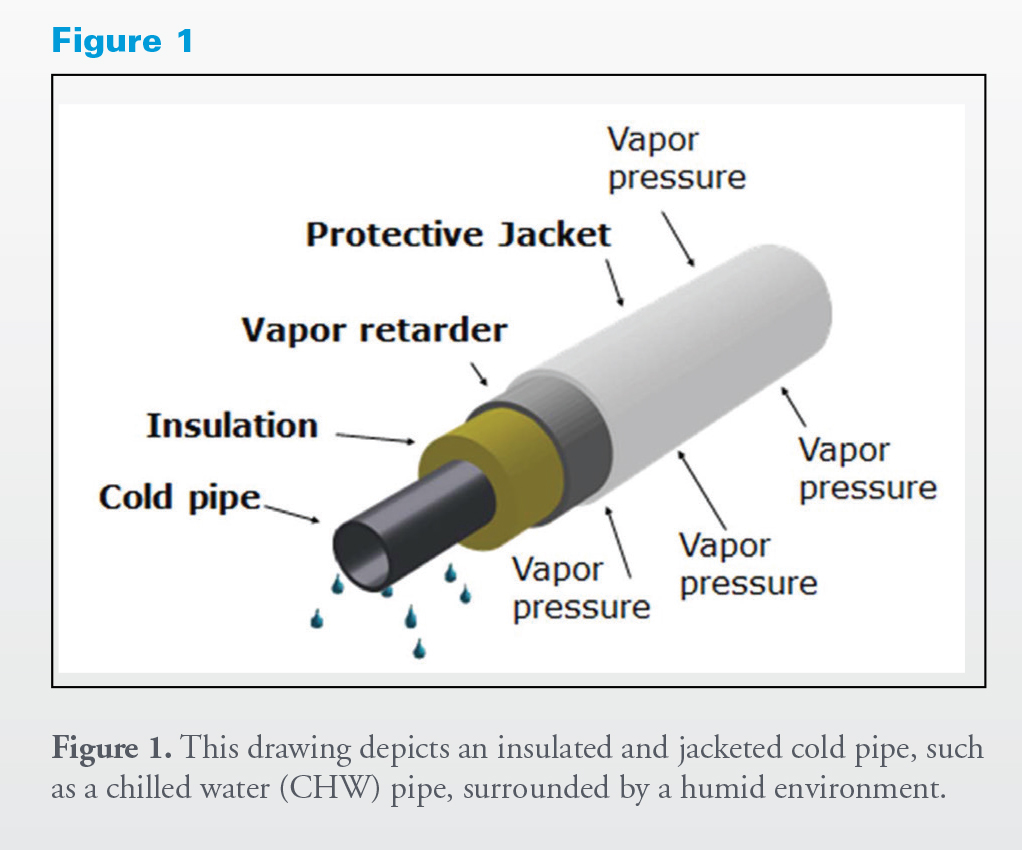

To start, we need to define “water vapor retarder”

and “jacketing.” ASTM C168 gives this definition for the former:

Water vapor retarder

(barrier), n—a material or system that significantly impedes the

transmission of water vapor under specified conditions.

Water vapor retarders are used

to limit the rate of water vapor migration from the ambient to a below ambient

surface. This is depicted in Figure 1.

A water vapor retarder may or

not include a separate protective jacket. However, for insulation materials

with high vapor permeability, there must be a continuous, tightly sealed vapor

retarder surrounding the insulation. As long as the pipe remains cold and the

environment is warm and humid, a vapor pressure difference will exist between

the environment and the pipe surface.

ASTM C168 defines a jacket as

follows:

jacket, n—a covering

installed over insulation.

Traditional Indoor Jacketing and Vapor Retarders

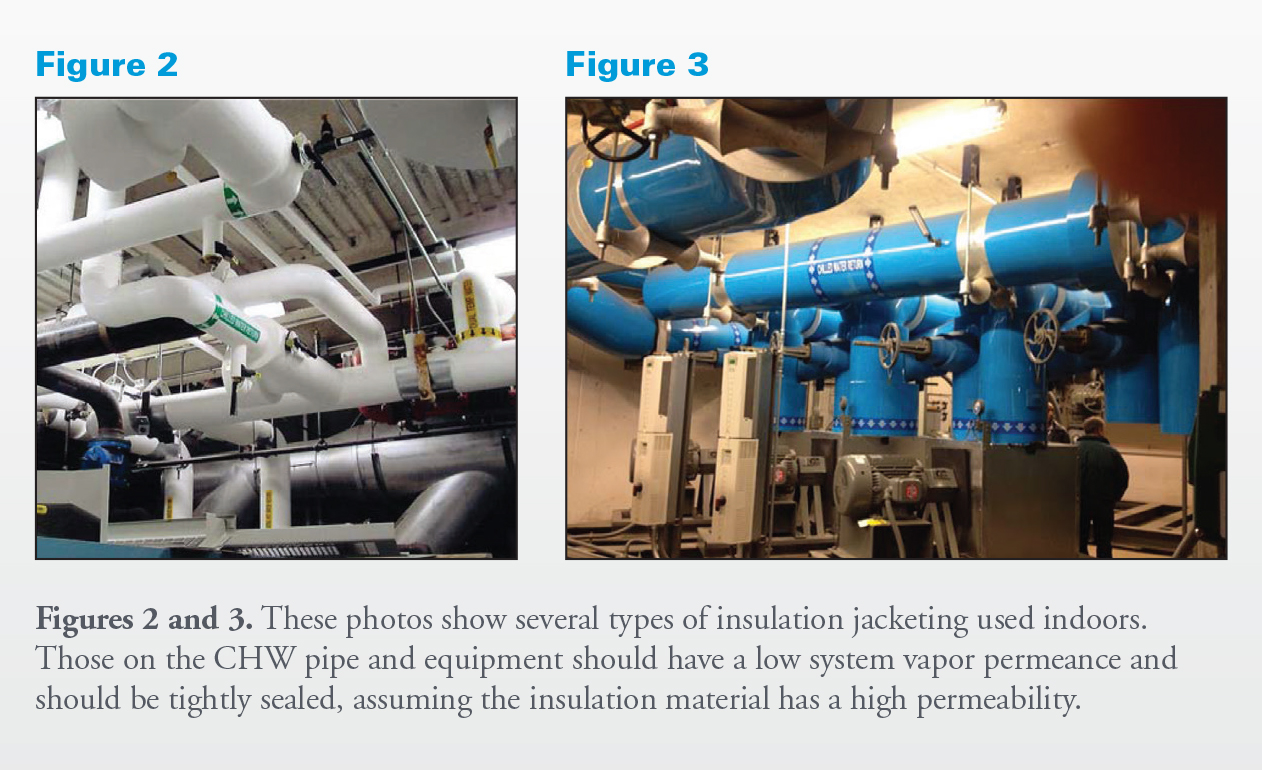

Jacket, or jacketing, exists in

different forms, as shown in the photos in Figures 2 and 3.

Failure Mechanisms of Vapor Retarder Systems

One reason for the development of new water vapor

retarders is the incidence of insulation systems failing on below ambient pipe

equipment in unconditioned buildings. This is a particular problem in locations

where the climate tends to be hot and humid. When a failure occurs on a below

ambient system with a sheet type of vapor retarder, it is likely due to at

least one of the following failure mechanisms:

- Water vapor

migration though holes in the aluminum foil in the vapor retarder (pin holes or

larger) - Water vapor

migration through joints in the vapor retarder (closures) - Condensed water

on the surface soaking into exposed paper on the all-service jacketing (ASJ)

when traditional ASJ is used (e.g., a Kraft paper—glass fiber scrim—0.00033

inch thick aluminum foil laminate) and not covered. This condensation may lead

to deterioration of the ASJ. - Mold growth,

which also may pose perceived or actual health and safety problems (the

specifics of which are beyond the scope of this article)

Figures 4 through 7 show

photographs of some of these problems.

While ASJ can be a good vapor

retarder, it is important that it be used in building spaces that are

conditioned and maintain low absolute humidity levels. Photos 4 through 7,

showing failed CHW insulation systems, were all taken in spaces that were

unconditioned most or all of the time. ASJ usually covers fiberglass or

phenolic foam pipe insulation, all of which have sufficiently high vapor

permeability values that they require a separate, continuous, tightly sealed

vapor retarder for successful performance.

Failures commonly encountered usually involve either unprotected,

traditional ASJ, or ASJ covered with unsealed polyvinyl chloride (PVC) in

unconditioned spaces in buildings located in hot and humid climates. There is

evidence that continuously sealed PVC jacket (either with solvent or PSA tape)

can significantly improve the vapor performance of ASJ in such applications.

Sealed PVC, installed over traditional ASJ, provides 3 major advantages over

exposed traditional ASJ: (1) lower system permeance, (2) water resistance, and

(3) physical protection. However, when the PVC is not continuously sealed in

these applications, that PVC jacketed system, on top of traditional ASJ, also

frequently fails in unconditioned spaces such as mechanical rooms and central

CHW plants.

Furthermore, in mechanical

rooms of buildings, traditional ASJ is frequently exposed to physical abuse,

including dripping or spraying water, which further shortens its life. It is likely

that exposed, traditional ASJ will not last long in a mechanical room

environment due to expected physical exposure. In any unconditioned space,

traditional ASJ does not perform well unless covered with a continuously sealed

PVC jacket. The results of research currently being conducted at Oklahoma State

University for ASHRAE Technical Committee 1.8 as Research Project RP-1646

should soon provide data to clarify some of these performance issues.

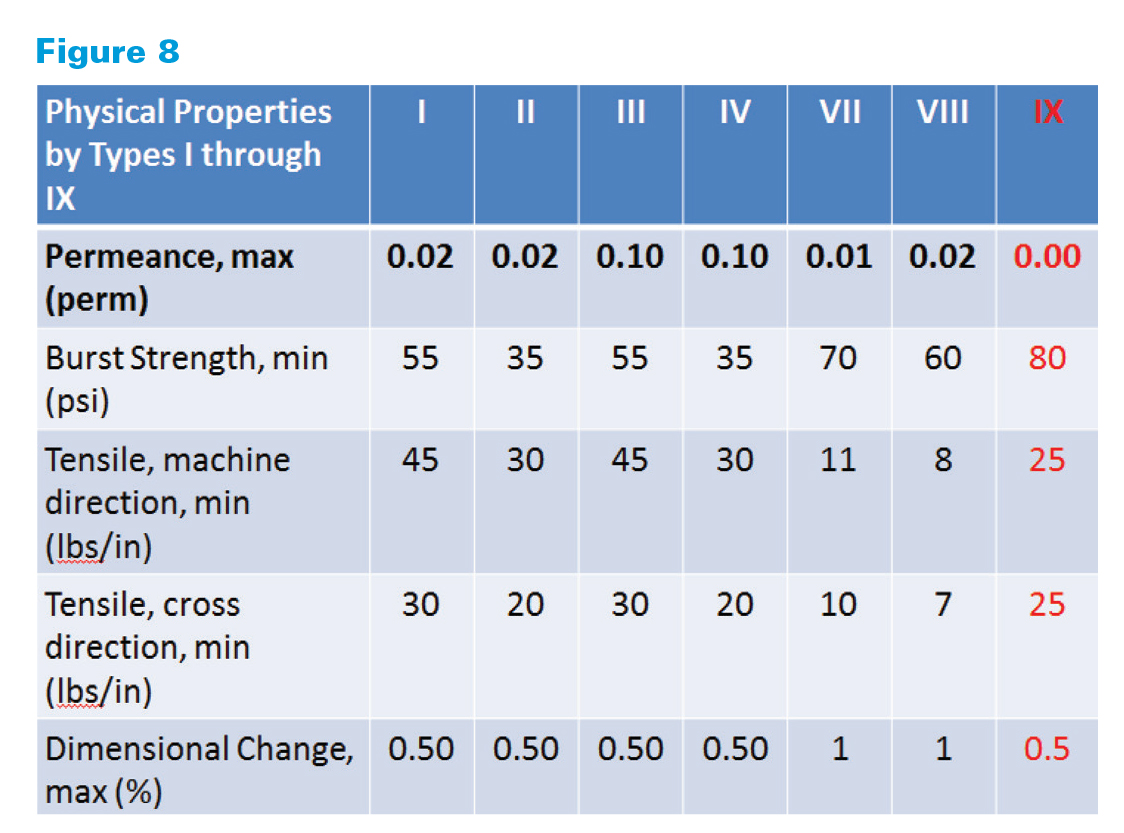

ASTM C1136 Vapor Retarders

Traditional indoor vapor retarders have been

addressed by ASTM specification C1136. These include ASJ, foil-scrim-kraft

(FSK), metalized polyethylene teraphthalate (MPET), and polyvinylidene chloride

(PVdC) materials. PVC jacket is not covered by C1136. Last year, ASTM added a

new Type IX material that is rated as having a water vapor permeance of 0.00

perm (meaning test results by ASTM E96 yield a permeance < 0.005 perm).

Figure 8 shows performance values of the recently updated C1136-12, with the

new Type IX shown in red in the last column.

Examining these values, it is apparent that this new ASTM C1136 Type IX

vapor retarder also has greater burst strength than the other vapor retarders,

and it has an average tensile strength. This material has a permeance of 0.00

perm because its composition includes aluminum foil with a thickness of at

least 0.001 inch (1 mil), which is at least 3 times thicker than the foil used

in traditional ASJ. An additional feature is that its composition includes no

exposed paper.

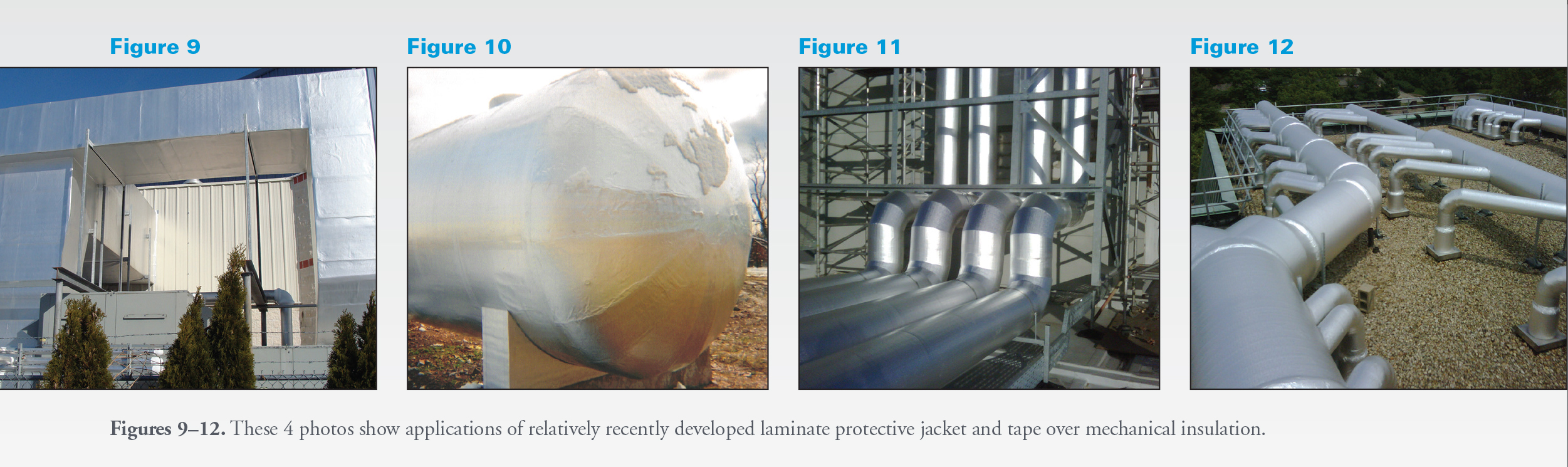

There is also a category of new

vapor retarders for use outdoors. Two specifications are under development at

ASTM Committee C16: one for a new product called “laminate protective jacket

and tape,” and another for a product called “modified asphalt jacket.” While

these are not always used as vapor retarders, like the ones covered by ASTM

C1136, all are rated as having a permeance of 0.00 perms. In addition, they are

much stronger than the Type IX vapor retarders, having burst strengths up to

400 pounds per square inch (psi) (compared to 70 psi for the C1136 materials)

and tensile strengths up to 150 psi (compared to 45 psi for the C1136

materials). While all are available with an aluminum finish, either smooth or

embossed, some are also available in different colors such as white, black, and

gray. Figures 9 through 12 show photos of these type materials in various

applications.

Joints

Achieving a

successful performance from a vapor retarder systems made with these or other

materials requires the following:

- Good design,

including vapor dams - Consistent,

high-quality materials - Proper

installation, with attention to providing continuous sealing, especially at

closures - Effective

operations and maintenance by facility owner - Recognition

that all systems have a limited life (not likely more than 30 years and

probably less for systems in high-humidity conditions)

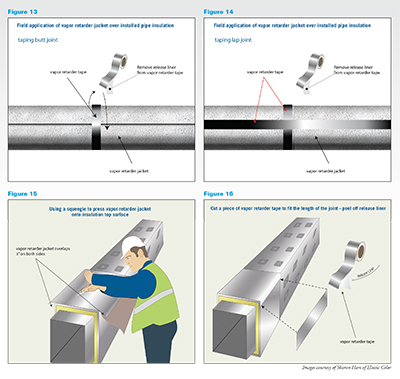

Figures 13 and 14 show some of

the steps for sealing pipe or cylindrical duct insulation jacketing using

compatible tape with a pressure sensitive adhesive (PSA).

On insulated ducts, laminate

protective jacket and tape can be used to weatherize the insulation system and,

in the process, provide a vapor tight seal. Figures 15 and 16 show installation

details.

Removable and Reusable Insulation for Components

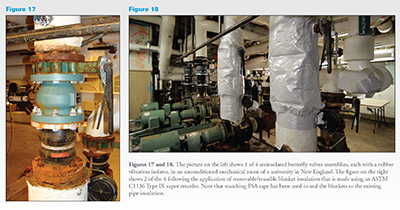

With the availability of the ASTM C1136 Type IX

vapor retarder and tape, both of which

include a PSA, it is now possible to make and apply a removable/reusable

insulation system on pipe system components in mechanical rooms. Sometimes

these components (butterfly valves, flange pairs, vibration

isolators, etc.) were insulated during construction, but when one of the

fittings leaks, mechanical maintenance personnel might cut off the insulation

and discard it to replace the leaking gasket or vibration isolator. The

individual replacing the parts may not reinsulate the components. In other

cases, these components were never insulated in the first place. Regardless,

the penalty for having no insulation on these components is energy waste and,

at least during much of the year, excessive condensation and subsequent

corrosion of the metal surfaces.

Using a special insulation kit

made with a continuous vapor retarder on both sides of a flexible blanket, and

with matching PSA and vapor retarder tape, custom shapes can be made by the insulation

craft laborers in the field and then installed on previously bare components.

When future removal is required for mechanical maintenance, some of the tape

can be removed, the insulation removed, the maintenance performed, and the

insulation then reinstalled (preferably by skilled insulation craft laborers)

using fresh tape. This saves time and money and reduces damage to the

insulation system. Figures 17 and 18 show before and after photos using this

type of kit made using an ASTM C1136 Type IX vapor retarder.

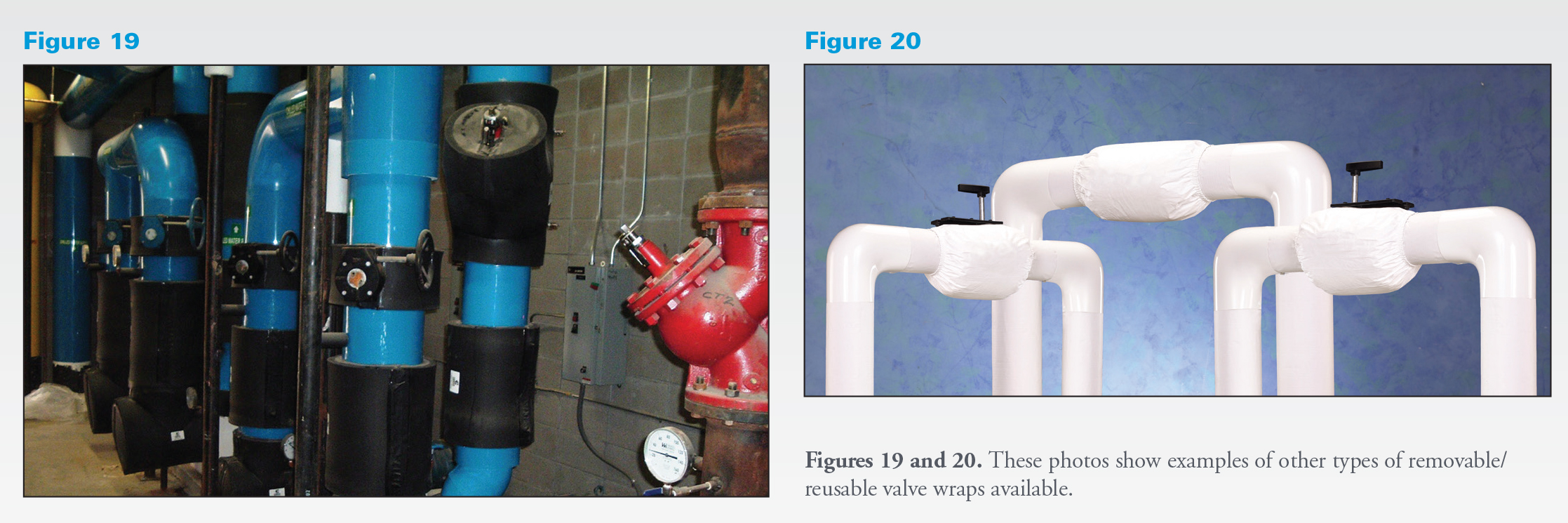

Some in the insulation industry

have objected to the less trim and consistent appearance of removable/reusable

kit insulation after installation. In its defense, the traditional appearance

is sacrificed to achieve removability and reusability, features that allow for

mechanical maintenance without damage to the system, reuse of the mechanical

insulation materials each time they are removed, and an insulation system that

can be tightly sealed against water vapor intrusion. However, there are other

product options available for components, including valves. The most important

thing is to insulate the whole system. Figures 19 and 20 show some of these

possibilities.

Summary

With the recent development of very low permeance

vapor retarders, new options have emerged for jacketing insulation systems.

These new materials have been designed for both indoor and outdoor use. All

have a permeance of 0.00 perm, and most are stronger—some much stronger—than

traditional vapor retarders. Many are available with pressure-sensitive

adhesives, and all have compatible tape with a PSA. It is now common to see

outdoor, insulated ducts with these new vapor retarders, and sometimes outdoor

insulated pipe and equipment. The use of the new ASTM C1136 Type IX vapor retarders,

with PSA tape, allows for tightly sealing the vapor retarder systems. This

material has also allowed for the development of a kit for making

removable/reusable insulation blankets for use on CHW mechanical room

components.