Knauf EPDs

About Knauf Earthwool 1000° Pipe Insulation with ECOSE Technology—Energy Efficient and Environmentally Sound

Knauf products that offer an EPD:

- Earthwool® 1000° Pipe Insulation

- Atmosphere® Duct Wrap

- Earthwool® Insulation Board

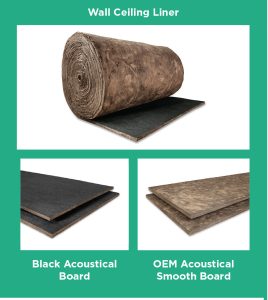

- Acoustical Smooth Board

- Atmosphere® Duct Liner

- Wall and Ceiling Liner M

- Black Acoustical Board

Visit www.knaufnorthamerica.com/en-us/sustainability

Knauf Earthwool® 1000° Pipe Insulation with ECOSE® is noted for its sustainability, thermal and performance properties, quality, and is the only formaldehyde-free fiber glass pipe insulation available in the market today. Earthwool® 1000° is a durable and resilient commercial and industrial fiberglass pipe insulation, designed to handle operating temperatures from 0°F to 1000°F, and is intended for use on piping and piping system components made from polymers (plastic), steel, copper, and stainless steel.

The main ingredients of Earthwool® 1000° Pipe Insulation with ECOSE® technology are recycled glass, sand, and bio-based, rapidly renewable ECOSE® binder. This composition delivers many benefits including energy savings, emissions reduction, resource use maximization, reduction in waste stream, and minimal waste generation due to longevity of service.

ECOSE® technology is our patented, bio-based binder. The unique binder holds our product together and gives the product its brown appearance. ECOSE® technology is a formaldehyde free-binder technology, based on rapidly renewable materials. It reduces embodied energy and delivers superior environmental sustainability.

The key recommended reasons to use Earthwool® 1000° Pipe Insulation with ECOSE® are energy savings, process control, condensation control, personnel protection, acoustical control, condensation control, and fire resistance/safety.

Ideal applications for the product, include:

Commercial

- Office

- Healthcare

- Education

- Institutional

- Public Safety

- Retail

- Sports & Entertainment

- Transportation Terminals

Industrial

- EV Battery Manufacturing

- Semiconductors/Microchip

- Automotive Components and Assembly

- Food and Beverage Production

- Power Generation

- Midstream and Upstream Oil and Gas

- Pulp & Paper

- Biofuels

- Chemical Processing

- Mining and Minerals

- Pharmaceuticals & Biotech

- Water/Wastewater Treatment

Earthwool® 1000° Pipe Insulation with ECOSE® is a highly versatile product that works well in a variety of piping systems, including:

Commercial Piping Systems & Equipment, HVAC and Plumbing

- Chilled Water Supply & Return

- Halocarbon Refrigerant Supply and Return

- Chilled Water Pumps and Vessels

- Heating Hot Water Supply & Return

- Steam Supply & Condensate Return

- Heating Hot Water, Steam, and Condensate Vessels

- Domestic Water, Hot and Cold

- Backflow Preventers

- Storm Water Drain Leaders

- Roof Drain Bodies

- Waste Water–Branch Drains, Main Stack

Industrial Piping Systems and Equipment, Building Services and Process Systems

- Product Conveyance Piping

- Compressed Air

- Drains

- Thermal Transfer Coils – Heating and Cooling

- Radiant Heaters

- Process Temperature Control – Heating or Cooling

- Steam Supply and Condensate Return

- Hot Water Supply and Return

- Hot Oil Loops

- Chilled Water – Supply and Return

- Refrigerants Supply and Return

Knauf uses Life Cycle Assessments (LCAs) to produce Environmental Product Declarations (EPDs) that detail the environmental impact — including CO2 emissions — of Earthwool® 1000° Pipe Insulation with ECOSE® from the cradle to the grave. For years, we have been measuring the embodied carbon of our products through the Life Cycle Assessment process and publishing results in Environmental Product Declarations.

For more information, visit https://www.knaufnorthamerica.com/en-us/products/pipe-insulation.