Life Cycle Assessment—an Insulation Products Perspective

“Science is 1 percent

inspiration and 99 percent perspiration.”

Despite the fact that the

above quote was recorded by Albert Einstein prior to the conception of the idea

of Life Cycle Assessment (LCA), it provides a perfect lead-in to this article.

The evolution of a social media-driven society has expanded a

demand for the “dumb it down” approach to explaining everything. For product

manufacturers, this is especially evident in the overabundance of

single-attribute certification programs and rating systems criteria popping up,

as well as recent attention given to the alarmist hazard-based approach. Each

of these is meant to serve the purpose of providing a convenient, yet narrowly-focused

definition of “green.” Environmental science, though, involves comprehensive

consideration of complex interactions of physical, chemical, and biological

processes. As a result, rendering judgments based on limited perspective (such

as a specific quality and/or life cycle stage of a product), opens the door to

increasing probability of unintended consequences from the broader viewpoint of

sustainability.

LCA is a technique developed for the purpose of understanding

and addressing the environmental impacts of products, processes, or services.

It involves quantifying and interpreting the energy and material resource

inputs, along with the environmental consequences of outputs, throughout a

product’s life cycle from raw material extraction to end of life

(cradle-to-grave). LCA is a science-based and holistic analytical method that

includes the

compilation of the consumption of energy and raw materials, as well as the

releases to air, water, and land.

As a result of recognition of its rigor and thoroughness,

along with the development of international standards that have improved its

utility, LCA has emerged as an essential tool in the evaluation of environmental

impacts associated with products. This recognition is particularly evident in

the building and industrial construction community where designers are

increasingly interested in the life cycle profile of the products and

assemblies that are being incorporated in specifications. As a result, it is

critical that the manufacturer, specifier, and user of insulation products grow

familiar with the LCA concept.

The purpose of this discussion is to provide overview

information regarding the key aspects of the LCA concept. The basic framework

for conducting an LCA study and a description of the established mechanisms for

effectively delivering the results, both internally and externally, are

included. The reader will find that the focus of much of the information is

building envelope thermal insulation, where substantial efforts have been

devoted in recent years to the credible representation of sustainability

through the LCA tool. It can be noted that a close connection can be

established between these efforts and initiatives to define the life cycle

profile of mechanical insulation products.

Development of the LCA Technique

Most are surprised that

the LCA concept has been discussed and applied for several decades. It has been

widely accepted for many years to provide a holistic perspective of

environmental impacts and, therefore, facilitate product development and

innovation, as well as comparisons of product systems that fulfill the same

function. However, with its foundation on detail and completeness come

challenges in its application. These include data collection consistency,

assumption development, and data availability limitations to all stages of the

life cycle by the LCA practitioner, just to name a few.

Technical committees of the International Organization for

Standardization (ISO) have prepared and updated documents for membership

approval for the purpose of standardizing aspects of the LCA technique. These

aspects include everything from establishing principles to delivering results

in a reliable and comparable fashion. This evolving and continuous maintenance

process is intended to address the challenges discussed above and establish

requirements that achieve global alignment with the application of the

technique while providing flexibility to focus on critical regional and product

system-related environmental impact issues.

Conducting an LCA Study

The

ISO standards internationally recognized for the purpose of conducting an LCA

are ISO 14040 1 and ISO 140442. The former establishes

the principles and framework of the LCA study, while the latter establishes its

requirements and guidelines. These standards state that “LCA addresses the

environmental aspects and potential environmental impacts?” and that an LCA

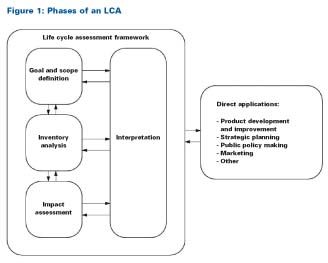

study is an iterative process involving four phases, as depicted in Figure 1

(ISO 14040) and described below.

1. Goal and scope definition

An LCA project begins with

the development of a concise statement of the objective for conducting the

study. This includes its intended use as well as who would be the target

audience for communicating the results. If the study is meant to be part of a

comparative assertion that will be disclosed to the public, the standard states

that the disclosure of such purpose shall be included in the definition of the

goal.

The value achieved through the execution of a credible LCA

lies in its characteristics of transparency, rigor, and thoroughness.

Therefore, an explicitly defined scope that describes the breadth and detail

required in order to adequately address the defined goal is critical. In

addition to providing the user of the results with a crucial understanding of

the context, the scoping serves as a blueprint for conducting the study. Key

aspects of the scope are the establishment of the functional unit and the

system boundary (see the glossary inset). It is useful to describe the product

system with a flow diagram illustrating each of the unit processes within the

system boundary and their relationships with one another. Examples of details

that are to be included in the definition of the scope are the study’s types

and sources of data, assumptions used, and limitations.

2. Inventory analysis

The “guts” of the LCA is

the data, and this phase of the process involves its collection and analysis.

The term that describes the data is the life cycle inventory, LCI. After

establishing a flow diagram representing the entire product system, the LCI

analysis involves the compilation of inputs to and outputs from each process

stage of the system boundary. The inputs must include all water and raw

material requirements, as well as the embodied energy of these raw materials

and additional energy associated with completing each individual process stage.

The outputs are all releases to air, land, and water. It should be noted that

transportation requirements between each stage are to be included.

Clearly, insulation supply chains can

involve dozens of specific processes and hundreds of flow inventories.

Therefore, data collection efforts likely will require the cooperation and

project goal understanding of raw material suppliers and perhaps upstream

entities. In addition, regional differences occur as a result of matters such

as energy conversion and material sourcing, which must be considered in the LCI

analysis.

3. Impact assessment

The third phase is life

cycle impact assessment, LCIA, where the aim is to evaluate the LCI results to

gain an understanding of the magnitude of the product’s potential life cycle

environmental impacts. In order to achieve meaningful results, the ISO standard

establishes mandatory elements of the LCIA. The first element is the selection

of the classifications of environmental concerns, or impact category(ies); the

representation of each category, category indicator; and the models employed to

establish corresponding characterization factor(s) applied to the LCI analysis

results. This selection process must be consistent with the goal and scope of

the LCA project. The second element is the classification step, or the

assignment of LCI results to specific impact categories; and the third is

characterization, through the calculation and summation of category indicator

results.

4. Interpretation

In the interpretation

phase, the results of the inventory analysis and impact assessment are

evaluated. Consistent with the defined goal and scope, the findings from these

evaluations are presented in the form of conclusions and recommendations. In

addition, limitations are to be identified and explicitly explained.

The evaluation in this final phase involves utilizing reams

of LCI and LCIA data and raw results with the goal of meaningful conclusions,

limitations, and recommendations, while achieving alignment with the

established goal and scope. This is clearly a daunting task. Not that it makes

it any less daunting, but ISO 14044 provides a framework for crossing this

canyon. This framework begins with identifying issues of significant magnitude

and importance. The evaluation process then moves to a series of assessments

regarding data quality, results consistency, and sensitivity of assumptions.

The credibility of the LCA study rests heavily on the level of due diligence

applied here. As indicated in Figure 1 with the opposing arrows to and from the

interpretation phase and each of the other three phases, this is an iterative

exercise. When a check discloses a flaw with the results, it is necessary to

go back to the calculations, assumptions, data sources, etc., and make the

necessary changes. At times, it may be determined that an identified gap

requires that the goal and scope definition be modified.

This final phase is the transition from the meticulous detail

and complexity involved in conducting an LCA to the application of its findings

for problem solving and decision-making. The successful LCA study is one that

is credible, transparent, and presented to the targeted audience in an

easy-to-understand fashion. This is particularly important when the intention

of the study includes comparing the LCA profile of the product studied to

competitive products performing the same function.

Final Report and Critical Review

Presenting results and conclusions

thoroughly and accurately to the target audience is a vital aspect of the LCA

concept. Section 5 (Reporting) of ISO 14044 provides explicit guidance on the

context requirements for reporting information from the study. Details shall be

included on all elements of the four phases with the purpose of providing

transparency to the reader regarding the execution of the study. In other

words, to establish the legitimacy of the conclusions in the eyes of the

reader, it is necessary to provide full disclosure of such matters as:

– The data and methods utilized and

why

– The assumptions made and why

As is the case with all aspects of the

study, the final report shall be structured in a manner consistent with the

goal and scope.

Despite the best intentions, commitment, and painstaking

efforts of the party sanctioning the study and the LCA practitioner executing

it, there still could remain a question in the viewpoint of the target audience

or other affected stakeholders (such as manufacturers of competitive products)

as to its legitimacy. Although not necessarily a means of fully overcoming

these doubts, the critical review process is intended to provide external

expert and unbiased perspective to the means at which the study was conducted.

ISO 14044 states the following:

“The critical review process shall

ensure that

– The methods used to carry out the

LCA are consistent with this International Standard,

– The methods used to carry out the

LCA are scientifically and technically valid,

– The data used are appropriate and

reasonable in relation to the goal of the study,

– The interpretations reflect the

limitations identified and the goal of the study, and

– The study report is transparent

and consistent.”

Under the ISO standards, a critical review is not a mandatory

requirement unless the study includes comparative assertions and will be

disclosed to the public.

A critical review panel is composed of a minimum of three

members, with one of the members assigned as the chair. It is appropriate for

the party sanctioning the study to select the chair, who will select the panel

members based on the goal and scope. Considering the broad-based analyses

involved in an LCA, it is important to select a panel with a diversity of

pertinent expertise. For instance, in the case of an insulation product LCA, it

is prudent to select at least one panel member with knowledge of the insulation

industry and markets.

The review process involves examination of the data,

methodologies used, and all background information of the study by the panel.

As a result, agreements of non-disclosure of proprietary data and information

between the party sanctioning the study, the LCA practitioner, and the members

of the panel are often executed. Following the panel’s initial examination, the

chair will typically request additional information, clarification, and,

perhaps, initial recommendations for changes. After the panel receives

responses, this process is repeated until panel members are comfortable that

they have fulfilled their purpose. The details of the exchange between the

panel and the LCA sanctioning party and practitioner are to be recorded in the

final report and made publicly available.

Product-Generic LCA

The substantial commitment

of resources required of the manufacturer initiating a full grass roots LCA

program for a portfolio of products can present a rationalization challenge. As

a result, consideration of a collaborative industry effort is prudent. The

potential for synergistic advantages is particularly high for generic products

with similar market property requirements and end-use applications, such as

individual insulation materials.

Typically, such an endeavor would be

initiated and conducted through the trade organization representing the

product(s) involved. Following the establishment of an initial project mission,

the assurance of a universal commitment by the participating product producers,

as well as their raw materials suppliers, is paramount. An important

preliminary action would be initial research on the availability and apparent

quality of updated inventory data for the key raw materials. As with an

individual company-based LCA, it normally makes a great deal of sense to hire

an outside expert to perform the actual study. LCA practitioners have the skill

set to conduct it efficiently and credibly. In addition, it is essential that

there is industry expertise providing project oversight and direction.

Therefore, it is advisable that trade organization staff or a member volunteer

be assigned to manage the project.

Once completed, and critically reviewed if possible, numerous

options for effective utilization are available to the organization and its

producer participants. For instance, an individual producer can use it to

develop its own LCA profile, saving substantial time and money in the process.

The Many Applications of LCA

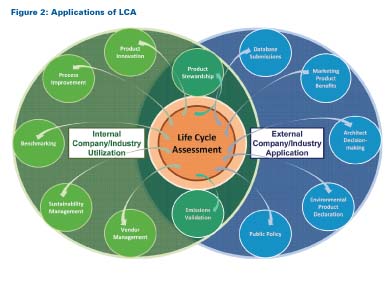

In examining the mass and

energy flows from a cradle-to-grave standpoint, one has opened a wide array of

possibilities for better understanding, exhibiting, and improving the

environmental aspects of a product(s). LCA is a tool that can be used for both

internal and external purposes. As discussed in the Goal and Scope Definition

phase of Conducting an LCA Study, though, it is essential to start the process

by deciding its “intended use as well as who would be the target audience for

communicating the results.” This section provides a brief description of the

mechanisms for sharing LCA results with various internal functional

organizations and external stakeholders.

The potential utility of an LCA study

for internal purposes requires understanding and engagement by several

functional groups within the organization. When leveraged as a core aspect for

operations and product development functions, the LCA results can play a

valuable role in advancing process improvements and product innovation. Also,

the cradle-to-grave perspective of the LCA tool provides insight into the

impacts of upstream processes and can contribute to an effective vendor

management program. In providing a foundation for a corporate sustainability

program, the development and maintenance of LCA profiles for a company’s

product portfolio is invaluable, if not essential. Armed with this detailed

knowledge of the environmental aspects of your company’s products and their

processes, reliable benchmarking against similar industries and competitors can

be achieved.

Incorporating

life cycle thinking into internal initiatives can have a positive impact on

market image and position. The use of this science-based, holistic approach to

representing and advancing environmental stewardship can provide positive

reinforcement to customers, stockholders, and the community. In addition, LCA

results play a role in validation of regulatory compliance, such as substance

emissions reporting.

There are several mechanisms for delivering life cycle

information outside of a company or industry. The most common is marketing

literature, where specific environmental aspects of a product are promoted in

order to highlight its benefits. Special considerations are often involved when

it comes to representing these aspects in either business-to-business or

business-to-consumer communications. Frequently, an organization wishes to make

claims that require a higher level of validation, transparency, and/or consistency

of representation. An example would be any case in which the claim would

include a comparative assertion. As a result, the external representation of

the LCA profile of a product or product system is best served through a

standardized process. Public or commercial databases and Environmental Product

Declarations (EPD), which are described in the next section, are emerging as

delivery mechanisms in the United States.

The National Renewable Energy Laboratory (NREL) manages the

U.S. Life Cycle Inventory Database 3, a publicly available

repository of LCI data that is collected and analyzed through similar methods.

Software tools offered by Athena®, EcoCalculator4, and

Impact Estimator5, are commercial LCA database tools for building

designers. The EcoCalculator provides a quick snapshot of the environmental

footprint for numerous pre-defined residential and commercial assemblies. The

Impact Estimator is a whole building tool for design teams to examine the

environmental impacts of various material and building product system choices.

Recently, the LCA concept is frequently

utilized to rationalize public policy in the sustainability arena, and

LCA-based threshold criteria are more commonly cited in defining policy

provisions. This is particularly evident in emerging green building standards

and codes, as well as sustainability product certification and green rating

systems, namely Leadership in Energy and Environmental Design (LEED).

Information on specific green building policy is provided later in this article.

Environmental Product Declaration

An important aspect of

environmental management is labels and declarations. These tools communicate

one or more characteristics of a product in terms of its environmental impacts.

A producer may utilize these tools in order to influence purchasers to make

decisions in favor of the company’s product. Therefore, they are intended to

expand demand for product through continuous improvement from an environmental

impact perspective. To ensure their usefulness, the information provided

through these tools must be accurate and verifiable. To facilitate development

of representative labels and declarations, ISO established a series of

standards starting with general principles in ISO 14020 6 and

including ISO 14025 7, establishing the procedures for EPDs. Also

relevant to this discussion is the market segment-specific standard, ISO 21930 8.

This standard supplements ISO 14025 by providing additional framework for

developing EPDs for building products.

The standards define an EPD as:

“Providing quantified environmental

data using predetermined parameters and, where relevant, additional

environmental information”

and state its purpose to be:

“Present quantified environmental

information on the life cycle of a product to enable comparisons between

products fulfilling the same function”

An EPD is based on LCA/LCI information, and the

“predetermined parameters” are set forth in ISO 14040 and ISO 14044. In other

words, EPDs present information from ISO-compliant LCA studies in such a way as

to provide the reader with a meaningful comparison of products that serve the

same purpose. To this end, ISO 14025-compliant, certified EPDs are founded on

transparent methodology and validated data, along with consistency in

presentation of results.

There are core elements of the procedural requirements of ISO

14025 and ISO 21930 that are important to note and understand. The first is the

selection of the program operator: the individual or organization contracted to

conduct various components of the EPD. The level of involvement by the program

operator in taking the project from a validated LCA study to the registration

and publication of the EPD is a matter of contractual agreement with the

client. However, the standards are explicit regarding the components that the

program operator must perform to achieve compliance.

Another element is the establishment of a functional unit.

The product system for the EPD being developed performs a primary function. The

functional unit is the amount of the product needed to perform a specified

level of that function. Of course, the function for insulation is resistance to

transfer of heat, so the functional unit is the amount required to provide a

certain R-value. This unit is the subject on which all the information in the

EPD is based and serves a convenient means of comparing products. A special

element for building products introduced through ISO 21930 is reference service

life. As the name suggests, this is the expected life span for the product

under in-use conditions. If the reference service life of a product is less

than the design life of the building, the number of replacements necessary over

the building life must be identified. This exhibits the importance of

durability of a product or assembly in the life cycle profile.

One last core element of EPDs to discuss here is that of

product category rules (PCR). In addition to the broad-based guidelines and

requirements presented in ISO 14025 and ISO 21930, there is a need to establish

a set of additional “rules” that are unique or customized to relevant aspects

of the “product category” before the EPD can be developed. A product category

is a group of products that serve equal functions, such as mechanical

insulations or building envelope thermal insulations. In such case that an

appropriate PCR is not available, effort must be made to involve a broad range

of stakeholders in the establishment of a harmonious, consensus-based, and

openly available ISO 14025-compliant document. An example would be the Building

Envelope Thermal Insulation Product Category Rules, developed by the Insulation

Coalition and verified and registered by UL Environment as the Program Operator

9.

Use-Phase Benefits

In conventional LCA

studies for durable building products, environmental encumbrances associated

with aspects such as required maintenance are evaluated during the relatively

long Use-Phase portion of the life cycle. This is where thermal insulation

performs its function of providing occupant comfort while limiting a building’s

(or an industrial process’) impact on the environment through conserving

operational energy. As a result, developing a perspective of the Use-Phase

benefits of installing insulation or using additional insulation in an assembly

or system is critical in achieving a comprehensive understanding of the life

cycle impacts during the early design and decision-making stage.

The prediction of energy performance for any given building

design is complicated by countless variables and influencing factors. Therefore,

it can be challenging for an insulation manufacturer to represent Use-Phase

benefits of its products for marketing purposes, such as through an EPD, in a

manner that is found to be credible by the intended audience. It is important

that this representation be established with the same level of rigor and

transparency as the LCA. A state-of-the-art, computer-based simulation program

that has the ability to model the listed criteria of Section G2.2.1 in Appendix

G of ASHRAE 90.1-2010 10 and tested according to ASHRAE Standard 140

11 (such as EnergyPlus 12) could fit the bill. In addition to

choice of location(s)/climate(s), selection of building design and numerous

system specifications are involved in the simulation exercise. With the purpose

of assessing the impact of various amounts of insulation, resource intensity

can be minimized and a level of credibility in the analysis can be appreciated

by the audience through the application of the Department of Energy’s

Commercial Reference Buildings Project 13. Through this project,

extensive market research has been adapted into 16 typical buildings that have

been fully designed and their operation systems specified for 16 U.S. locations

with fully populated EnergyPlus input files. There are three versions of each

input file, providing widespread representation of newly constructed and

existing commercial buildings in this country.

Glossary of LCA Terms

Category Indicator. A quantifiable representation of an impact category?e.g.,

infrared radioactive forcing for

climate change.

Characterization Factor. A factor derived from a characterization model for

expressing a particular environmental intervention in terms of the common unit

of the category indicator (e.g., photochemical ozone creation potential of methanol).

Functional Unit. The quantified function provided by the product system(s)

under study, for use as a reference basis in an LCA?e.g., 1,000 hours of light

(adapted from ISO).

Impact Category. A class representing environmental issues of concern to which

environmental interventions are assigned?e.g., climate change, loss of

biodiversity.

Life Cycle Impact Assessment (LCIA). The third phase of an LCA, concerned

with understanding and evaluating the magnitude and significance of the

potential environmental impacts of the product system(s) under study.

Life Cycle Inventory (LCI). The second phase of an LCA, in which the relevant

inputs and outputs of the product system(s) under study throughout the life

cycle are, as far as possible, compiled and quantified.

Product Category Rules (PCR)*. A set of specific rules, requirements,

and guidelines for developing Type III

environmental declarations for one or more product categories.

Program Operator*. Body or bodies that conduct(s) a Type III environmental

declaration program.

Reference Service Life**. Service life of a building product that is known or

expected under a particular set?i.e., a reference set?of in-use conditions, and

that may form the basis of estimating the service life under other in-use

conditions.

System Boundary. The interface between a product system and the environment

system or other product systems.

Source: Handbook on Life

Cycle Assessment. 7th ed. New York: Kluwer Academic Publishers, 2004.

* Denotes source is

ISO-14025 7

** Denotes source is

ISO-21930 8

References

1International Organization for Standardization (ISO).

2006. ISO 14040:2006 Environmental management ? Life cycle assessment ?

Principles and framework. Geneva, Switzerland.

2International Organization for Standardization (ISO).

2006. ISO 14044:2006 Environmental management ? Life cycle assessment ?

Requirements and guidelines. Geneva, Switzerland.

3National Renewable Energy Laboratory (NREL). U.S. Life

Cycle Inventory Database. www.nrel.gov/lci/.

4Athena Sustainable Materials Institute. EcoCalculator.

www.athenasmi.org/our-software-data/ecocalculator/.

5Athena Sustainable Materials Institute. Impact

Estimator. http://www.athenasmi.org/our-software-data/impact-estimator/

6International Organization for Standardization (ISO).

2000. ISO 14020:2000 Environmental labels and declarations ? General

principles. Geneva, Switzerland.

7International Organization for Standardization (ISO).

2006. ISO 14025:2006 Environmental labels and declarations ? Type III

environmental declarations ? Principles and procedures. Geneva, Switzerland.

8International Organization for Standardization (ISO).

2007. ISO 21930:2007 Sustainability in building construction ? Environmental

declaration of building products. Geneva, Switzerland.

9Underwriters Laboratories Inc., 2011. Building

Envelope Thermal Insulation Product Category Rule Number UL 110116. www.ul.com/global/documents/offerings/businesses/environment/PCRs/ULE_PCR_EnvelopeThermalInsulation.pdf.

10 American Society of Heating, Refrigerating and

Air-Conditioning Engineers, Inc. 2010. ANSI/ASHRAE/IESNA Standard 90.1-2010

Energy Standard for Buildings except Low-Rise Residential Buildings. Atlanta,

GA.

11 American Society of Heating, Refrigerating and

Air-Conditioning Engineers, Inc. 2004. ANSI/ASHRAE Standard 140-2004 Standard

Method of Test for the Evaluation of Building Energy Analysis Computer

Programs. Atlanta, GA.

12 U.S. Department of Energy, Energy Efficiency and

Renewable Energy. EnergyPlus. http://apps1.eere.energy.gov/buildings/energyplus/

13 U.S. Department of Energy, Energy Efficiency and

Renewable Energy. Commercial Reference Buildings. http://www1.eere.energy.gov/buildings/commercial_initiative/reference_buildings.html.