Mechanical Insulation Simple Calculators: A Guide to the Energy and Condensation Control Calculators

History

As a part of efforts by the Department of Energy’s Advanced Manufacturing Office to improve the energy efficiency of the U.S. industrial and commercial sectors, the National Insulation Association (NIA) and its alliance partners worked together to design, implement, and execute the Mechanical Insulation Education & Awareness Campaign (MIC).

Calculators

The goal is a program to increase awareness of the energy efficiency, emission reduction, economic stimulus, and other benefits of mechanical insulation in the industrial and commercial markets. An integral component was the development of a series of Insulation Calculators. The calculators provide the user instantaneous information on a variety of mechanical insulation applications in the industrial, manufacturing, and commercial markets. Topics include:

- Condensation Control for Horizontal Pipe

- Energy Loss, Emission Reduction, Surface Temperature, and Annual Return (two calculators: one for Equipment, and one for Piping)

- Financial Returns/Considerations

- Estimate Time to Freezing for Water in an Insulated Pipe

- Personnel Protection for Horizontal Piping

- Temperature Drop for Air in an Insulated Duct or Fluid in an Insulated Pipe

The calculators are online www.insulation.org/calculators. They are fast, free, and functional tools that make it easy to discover energy savings, financial returns, as well as other information used in the design of mechanical insulation systems for above- or below-ambient applications.

This article, including text excerpted from the Design Guide, provides an overview and guide to use of the calculators for energy and condensation control for horizontal piping.

Energy Calculator for Horizontal Piping

As an aid to understanding the relationships between energy, economics, and emissions for insulated systems for horizontal pipe applications, a simple spreadsheet calculator was developed. A similar calculator for equipment, vertical flat surfaces, also was developed.

The algorithms used in the energy calculators are based on the calculation methodologies outlined in ASTM C680-10 – Standard Practice for Estimate of the Heat Gain or Loss and the Surface Temperatures of Insulated Flat, Cylindrical, and Spherical Systems by Use of Computer Programs.

The pipe calculator estimates the heat flows through horizontal piping assuming one-dimensional, steady-state heat transfer. Information concerning a hypothetical insulation system (e.g., the length of run, pipe size, operating temperature, ambient temperature and wind speed, insulation material, and surface emittance of a proposed insulation system) may be input by the user. Calculated results are displayed for a range of insulation types and thicknesses, and include surface temperature, heat flow, annual cost of fuel, installed cost, payback period, annualized rate of return, and annual CO2 emissions.

Other geometries and more complex insulation systems may be analyzed using publicly available software such as the 3E Plus® Insulation Thickness Computer Program. 3E Plus was developed by the North American Insulation Manufacturers Association and is

available at www.3eplus.org.

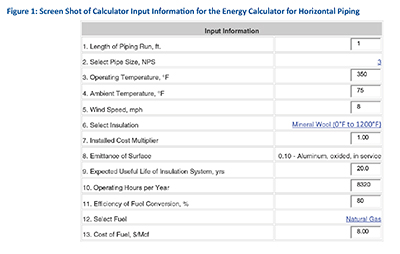

The Energy Calculator for Horizontal Piping requires “Information ” for thirteen variables (see Figure 1). Results are updated as each input variable is entered. Below are instructions and additional information for each input variable. Sample inputs appear in a box, after each instruction.

Figure 1

- Line 1. Enter the length of the piping run in linear feet 1

- The default value is 1 linear foot, but you may enter any length of piping run. The initial “Results” section contains installed cost for the default footage (1 linear foot) for the nominal pipe size and material selected in lines 2 and 6, respectively. You may find it helpful to review the cost information for 1 linear foot before completing line 1 and line 7, the cost multiplier.

- Line 2. Select Nominal Pipe Size, NPS 3

- The default value is an NPS of 3″. Using the drop-down box, however, you can select any pipe size from 0.5″ to 14″. Above 14″, we suggest you refer to the 3E Plus program or take another approach.

- Line 3. Enter average operating (process) temperature for the period of operation 350

- Enter the average below- or above-ambient operating temperature in degrees Fahrenheit (°F)

- Line 4. Enter average ambient temperature for the period of operation 75

- Enter the average ambient temperature in °F

- Line 5. Enter average wind speed for the period of operation (if unknown, use 1 miles per hour for indoor, 8 mph for outdoor) 8

- Enter the average wind speed in mph. If unknown, it is suggested you use 1 mph for indoor and 8 mph for outdoor applications.

- Line 6. Select an insulation material. Note: Calculator does not screen for material temperature limitations—Use caution. Mineral Wool (0°F to 1,200°F)

- The default material is mineral wool; however, you may use the drop-down box to select another insulation material:

- Calcium Silicate (80°F to 1,200°F)

- Cellular Glass (-450°F to 800°F)

- Elastomeric (297°F to 220°F)

- Fiberglass (0°F to 850°F)

- Mineral Wool (0°F to 1,200°F)

- Polyisocyanurate (297°F to 300°F)

You will note that each of the material options contains a general operating temperature range. Should you wish to use a material that is not listed, you will need to refer to the 3E Plus program. The simple calculators do not have the capability of utilizing user-supplied thermal curves. Thermal conductivity values for the listed materials are based on ASTM material specification values.

- Line 7. Enter a cost multiplier to modify the default installed costs (e.g., enter 1.10 to increase costs 10%) 1.00

- As noted under line 1, the calculator contains default costs for each type of material and pipe size. If you enter 1 linear foot in line 1, select the size pipe in line 2, and the insulation material in line 6, you can review the default cost for a linear foot for various insulation thicknesses in the “Results” section. If “NA” appears for a given insulation thickness, that indicates that the thickness is normally not available for the selected material. You can adjust the cost up or down by simply modifying the multiplier. Enter 1.10 if your cost is 10% higher. Enter .80 if your cost is 20% lower.The installed costs were developed from industry sources and represent single-layer installations. They include aluminum jacketing, but do not include vapor retarders or vapor sealing. They may be viewed as higher than actual, but that view will vary greatly depending upon labor cost, operating conditions, insulation system, and a variety of other factors. Understanding that those variances exist is the reason the multiplier approach was selected.

- Line 8. Enter the effective emittance of the exterior surface (see Design Data>Table 1 for guidance) 0.10-Aluminum, oxided, in service

- A definition of emittance is often requested. Technically, emittance is defined as the ratio of the radiant flux emitted by a specimen to that emitted by a blackbody at the same temperature and under the same conditions. In simpler terms: the darker the surface, the more radiant heat is absorbed. The default value is 0.10, which represents aluminum that has oxided in service. However, using the drop-down box, you can select the typical emittance value for eleven of the commonly used insulation jacket finishes.

- Line 9. Enter the expected life of the insulation system in years 20.0

- This value is the economic life used for financial return calculations. The default value is 20 years. You can enter any number of years.

- Line 10. Enter the number of hours per year of system operation (e.g., 8,760 for full year operation) 8320

- Some systems may not operate 24/7/365. You can input the estimated number of operational hours anticipated.

- Line 11. Enter the conversion efficiency of the system in percent 80

- If you do not know the conversion efficiency for the energy source, you can use the following typical conversion efficiencies for various systems:

- Fossil Fuel Boilers (Non-condensing) 65-85%

- Fossil Fuel Boilers (Condensing) 80-95%

- Electric Resistance Boilers 92-96%

- Electrically Operated Chillers 300-700%

- Absorption Chillers 60-100%

- Line 12. Select the fuel used Natural Gas

- Using the drop-down box, you can select one of five types of fuel: Natural Gas, Oil, Propane, Coal, or Electricity.

- Line 13. Enter cost of fuel if known or use default value 8.00

- A typical default cost for each of the fuel types is provided ($/Mcf). You have the option of simply entering your actual cost, if known, or accepting the default cost.

Based upon the input information you entered, the “Results” section provides detailed information for various insulation thicknesses. An example using the default values for all input variables is shown in Figure 2.

Figure 2

Condensation Control Calculator-Horizontal Pipe

This calculator estimates the thickness of insulation required to avoid condensation on the outer surface of an insulated horizontal steel pipe. Input data includes the operating temperature, the ambient conditions (temperature, relative humidity, and wind speed), and details about the insulation system (material and jacketing).

The insulation materials included in this calculator were selected to be representative of some of the materials commonly used in the industry. The list is not exhaustive, and other materials are available. Also note that some materials are not available in all of the sizes and thicknesses covered by these calculators, and some are available in sizes and thicknesses not listed.

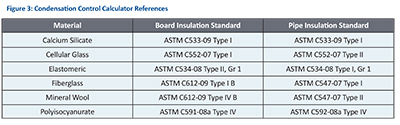

Thermal conductivity data for the materials included in the calculator were taken from the appropriate ASTM material specification. Figure 3 identifies the ASTM specification and the material type and/or grade used in the calculator.

Figure 3

The calculator requires “Input Information” for seven variables. Here are instructions for each data field and additional information for each. As before, sample inputs appear in a box after each step.

- Line 1. Select Pipe Size, NPS 4

- The default value is an NPS of 4″, but by using the drop-down box, you can select any pipe size from 0.5″ to 24″.

- Line 2. Enter average operating (process) temperature, °F 40

- The default value is 40°F, but other values may be entered.

- Line 3. Enter average temperature of the air surrounding the pipe 80

- The default value is 80°F; however, you should enter the average surrounding or ambient operating temperature, in Fahrenheit, for the area in question.

- Line 4. Enter relative humidity of the ambient air 80

- The default value is 80%. You should enter the specific design relative humidity for your application, however. From a design perspective, it is better to use a reasonably higher-than-average or worst-case value.

- Line 5. Enter the wind speed of the ambient air (if unknown, use 0 mph for worst-case conditions) 0

- As noted, when in doubt, use 0 mph, which represents the worst-case conditions.

- Line 6. Select an insulation material Cellular Glass

- You may use the drop-down box to select one of the insulation materials. Should you wish to use a different material than one of the ones listed, you will need to refer to the 3E Plus program. Thermal conductivity values for the listed materials are based on ASTM material specification values.

- Line 7. Select the effective emittance of the exterior surface 0.90-All

Service Jacket - As with the energy calculator for horizontal piping, a definition of emittance is often requested. In simple terms, the darker the surface, the more radiant heat is absorbed. The default value is 0.90, which represents All Service Jacket; however, using the drop-down box, you can select the typical emittance value for eleven commonly used insulation jacket finishes.

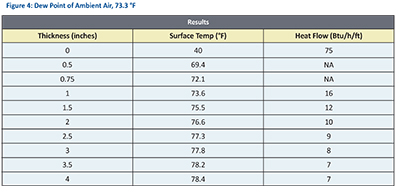

The “Results” section highlights the thickness of insulation required to avoid condensation on the outer surface of the insulation jacket. This thickness yields an average surface temperature that is greater than the dew-point temperature plus a safety factor of ¾°F. It should be noted that for some high-humidity conditions, regardless of the insulation type or thickness, it is impossible to avoid condensation on the outer surface. An example using the default values for all input variables is shown in Figure 4.

Figure 4

Summary

The Simple Calculators are intended to provide the user with online, at-your-fingertips, snapshot information to help answer some the most frequently asked questions about benefits and design considerations of mechanical insulation systems. They do not address every insulation material or application conditions-thus the phrase, Simple Calculators. Other insulation systems and more complex applications may be analyzed using the 3E Plus program.

Whether you need basic insulation information or are designing a complex insulation system, the Design Guide is the best resource for the novice or the experienced user alike, with everything you need to know about the design, selection, specification, installation, and maintenance of mechanical insulation. These tools can be very helpful in designing a mechanical insulation system, allowing the user to easily determine the many benefits and value of mechanical insulation.