ROCKWOOL Technical Insulation- Fire and Water

ROCKWOOL Technical Insulation

rti.rockwool.com

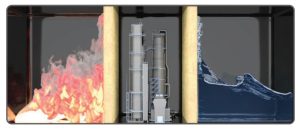

Stone (mineral) wool insulation can make a difference for both safety and performance in high-temperature piping and equipment. Superior solutions work as a physical barrier between the threats posing a risk to facility infrastructure.

Water

Recent advancements have greatly improved stone wool insulation in terms of safety, reliability, and economics—by impeding water ingress to mitigate corrosion under insulation (CUI) and providing 2 hours of passive fire protection.

Staying ahead of water is a critical challenge for all industrial plants. Water intrusion can occur under every type of insulation system, and if not dealt with in the design phase, managing CUI becomes even more dangerous and costly. Insulation materials are an important system component that must be optimized to help mitigate CUI.

ROCKWOOL® Technical Insulation (ROCKWOOL) developed an innovative solution to help combat this common industry problem: ProRox® with WR-Tech™ (Water Repellency Technology). WR‑Tech is an advanced technology based on a unique binder that repels water. It is a hydrophobic, inorganic, resin-based additive that coats each individual fiber of the insulation during production.

WR-Tech is an award-winning technology, as a distinguished recipient of the Materials Performance Corrosion Innovation of the Year Award, recognized by corrosion experts as a proven technology that is an outstanding solution for CUI mitigation potential.

To continuously improve the performance of insulation materials, ROCKWOOL recently expanded WR-Tech into our ProRox MA 960 mat/blanket. WR‑Tech was first successfully launched in mandrel-wound pipe sections, where it quickly demonstrated reliable, long-term CUI protection. ProRox MA 960 with WR-Tech is suitable for applications such as large-diameter piping/equipment and where additional flexibility is required.

ProRox with WR-Tech is a durable choice to keep plants dry—now, and in the long run.

Fire

In addition to water, fire also poses a significant risk to industrial facilities that contain or process hydrocarbons, such as refineries or petrochemical plants. Hydrocarbon fires are known as high-intensity fires that are very hazardous due to their rapid rise in flame temperature. Typically reaching peak temperature in under 5 minutes, they allow little time to react and have a greater potential for damage to people, equipment, and the surrounding environment. Therefore, passive fire protection (PFP) is essential for process safety, and critical to piping equipment integrity, impeding the flow of heat and/or spread of fire.

ROCKWOOL is excited to announce the launch of our NEW solution for PFP against hydrocarbon pool fires: ProRox PS 680 with FR-Tech™ (Fire Resistant Technology).

FR-Tech incorporates an innovative fiber structure and chemistry to ensure mechanical and chemical stability during a fire. FR-Tech is a demonstrated, safe solution. In addition to stone wool being naturally fire resilient and non-combustible, ProRox PS 680 with FR-Tech has been tested and evaluated to the industry-standard UL 1709 fire curve, providing 2 hours of PFP.

Importantly, PS 680 with FR-Tech also includes WR-Tech, creating a dual-solution that is “The Difference Between”—the difference between elemental threats that pose a risk and proven protection.

For further information, please visit rti.rockwool.com.