Understanding the Boiler MACT Regulation for Area and Major Sources

Rarely is it that a specific environmental regulation

becomes so high profile as the recent Industrial Boiler Maximum Achievable

Control Technology (Boiler MACT) regulation, which has been the subject of

myriad bills that have come before the U.S. Congress. The Boiler MACT has been

cited as a clear division point between the two major political parties in the

United States, with the ultimate fate of facilities to be determined within

months after the election in November 2012. The political back and forth has

led to a limbo status for the major source regulation?with “major source”

defined by the U.S. Environmental Protection Agency (EPA) as “a stationary

source or group of stationary sources that emit or have the potential to emit

10 tons per year or more of a hazardous air pollutant [HAP] or 25 tons per year

or more of a combination of hazardous air pollutants.” This regulation will be

critical for those in the insulation trade: insulation is critical for

industrial boilers and process heaters as it is employed for the reduction of

heat loss and the increase of boiler efficiency; and it is one method of

reducing emissions outlined in the Boiler MACT regulation, potentially lowering

fuel costs and usage by enhancing the boilers’ steam system insulation.

The many recent changes to the Boiler MACT standards have

left industries confused and unsure of the reporting, testing, monitoring, and

further compliance measures that must be taken to operate within the standards.

In 2011 and 2012, the EPA released extensive revisions to the National Emission

Standards for Hazardous Air Pollutants (NESHAPs). The standards are divided

between 40 CFR Part 63 Subpart JJJJJJ for affected “area sources”?defined as

“any stationary source that is not a major source” ?and 40 CFR Part 63 Subpart

DDDDD for major sources, as defined by the respective air permits of the

facilities. Of the units affected by the regulation, the most rigorous emission

limits are assigned to those boilers and process heaters employing coal,

distillates, and biomass as fuels.

The regulations have had a bumpy recent history. A version of

the Boiler MACT standards was released in April 2010 and received over 4,800

comments from businesses and communities, some of which led to a change in

proposed subcategories and emission limits. In turn, the EPA published the

regulation into the Federal Register on March 21, 2011. The current final form

of the standard under Subpart JJJJJJ (with proposed amendments) was published

to the Federal Register on May 18, 2011. On March 13, 2012, the EPA issued a No

Action Assurance Letter for area sources. The EPA determined that further

public review was required for Subpart DDDDD and in May 2011, under the

authority of the Administrative Procedure Act, announced a delay of effective

dates of standards for major sources. On January 9, 2012, the U.S. District

Court for the District of Columbia, in Sierra Club versus Jackson, vacated the

EPA’s administrative stay of the Boiler MACT, thus making the March 2011 major

source standard effective. On February 7, 2012, the EPA issued a No Action

Assurance Letter for major sources. Currently, the EPA proposes to issue the

final rule before the compliance dates for existing sources.

The current Boiler MACT standards divide facilities’ boilers

into subcategories defined by boiler type, capacity, and fuel type. Based on

this information, a source must meet emission limits, work practice standards

(including tune-ups and energy assessments), and operating limits, and/or

demonstrate initial/regular compliance. Whether the facility is considered to

be new or existing also will determine if it is subject to the varying work

practice standards and requirements. Sources also are considered new if they

switch from one fuel to another (primary or secondary) that is applicable under

the regulation. Below are some critical facts regarding the current Boiler MACT

standards, how they may apply, and what impact they could have for your

facility.

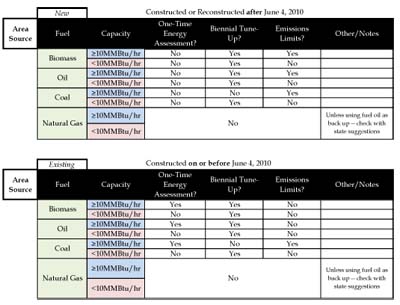

Area

Source Requirements

Area

source requirements (40 CFR Part 63 Subpart JJJJJJ) affect facilities with the

potential to emit less than 10 tons per year (tpy) of any single HAP, and/or

less than 25 tpy of combined HAPs. These regulations affect sources with

boilers defined as existing, new, or reconstructed.

This rule covers boilers burning coal, oil, biomass, or

non-waste materials, but not solid waste as fuels. This also includes natural

gas-fired boilers if they use fuel oil as a backup. All other propane or

natural gas-fired boilers are exempt from the area source regulations. Also,

depending on status and fuel type, there are emission limits for mercury,

particulate matter (as a surrogate for non-mercury metals), and carbon monoxide

(as a surrogate for organic air toxics).

Another aspect of this subpart critical for existing sources

is timing for compliance. All area sources considered subject to JJJJJJ were

initially required to comply with emission limits or an energy assessment by

March 21, 2014, and work practice standards by March 21, 2012. A Notification

of Compliance to work practice standards (including a boiler tune-up) is due to

the EPA by July 19, 2012. However, under the No Action Assurance Letter, the

EPA extended the compliance and notification dates for initial tune-ups after

several deliberations (and many companies already achieving the preliminary

compliance date). Facilities have been granted a No Action Assurance by the

USEPA. This does not require subject facilities to meet the originally-stated

compliance deadline of March 21, 2012. It should be recognized that biennial

tune-ups must be conducted no more than 25 months after the previous tune-up.

For new sources, compliance must be achieved upon commencement

of operations. This includes submittal (within 30 days after operation of

subject equipment begins) of a Notification of Compliance Status to these

standards. If you are required to conduct performance tests, you are obligated

to submit a Notification of Compliance to the EPA within 60 days of completing

the performance test. Tables are included below to provide a basic overview of

what needs to be completed to meet the area source standard for boilers.

Major Source

Requirements

Major

source requirements (40 CFR Part 63 Subpart DDDDD) affect facilities with the

potential to emit greater than or equal to 10 tpy of any single HAP, and/or

greater than or equal to 25 tpy of combined HAPs. This rule includes boilers

and process heaters burning natural gas, fuel oil, coal, biomass (e.g., wood),

refinery gas, or other gas to produce steam. Unlike Subpart JJJJJJ, Subpart

DDDDD also includes natural gas/propane/clean fuel boilers. The requirements

contain subcategories with very specific requirements. Of the roughly 14,000

major source boilers and process heaters in the United States, 88 percent are

required to conduct annual or biennial tune-ups; and 12 percent are required to

meet emission standards if those standards are not already met. New and

existing natural and refinery gas units are subject to tune-ups every 2 years,

regardless of operating rate. Other affected boilers are subject to limits on

emissions of mercury, dioxin, particulate matter, hydrogen chloride, and carbon

monoxide, based on fuel type or combustion. Unfortunately, at the time of the

completion of this article, the final rule was not yet published. Therefore,

some of this information may change and should be confirmed before proceeding.

New proposals may see changes in the finalized version of the rule, to be

published later in 2012 or early 2013. Much of the outcome of this regulation

is seen to be determined by the outcome of the November 2012 presidential and

congressional elections.

Additional

Compliance Considerations

For

all subject facilities, both major and area source, certain boilers also must

demonstrate continuous compliance through stack testing, continuous monitoring,

recordkeeping, and reporting. In addition, facilities must submit initial

notification and a Notification of Compliance Status within several months

(exact numbers and dates will be solidified and included in finalized

standards). For area sources, an Annual Compliance Certification report is due

by March 1 of each year. Recordkeeping requirements can include permits,

continuous monitoring data, deviation reports, fuel use, performance test,

energy assessment reports, tune-up documentation, stack test data, and any

site-specific monitoring plans.

It is critical to check with your state regulatory agency

before rushing to comply with some of these area source regulations. For

instance, in Indiana, a facility would not necessarily be subject to the

regulation if that facility has boilers that primarily run on natural gas, with

fuel oil as a backup fuel source. The exemption applies if you use fuel oil at

any time other than in a period of curtailment or during periodic testing (less

than 48 hours within a 12-month period). A period of curtailment refers to any

time when gas is cut off and it is beyond a facility’s control (e.g., during a

natural disaster). If a facility in Indiana has an air permit and this is not

explicitly stated in that permit, it may be wise to pursue a permit

modification stating that fuel oil is a backup fuel used strictly during periods

of curtailment or during periodic testing. While this specific regulatory

nuance applies to Indiana, individual state regulatory agencies should be

consulted to see if a similar detail may be applicable to your facility.

A large point of concern for many facilities, both major and

area sources, is the prospect of completing an energy assessment by March 21,

2014. An on-site energy assessment consists of the following major points, to

be conducted by a qualified energy assessment professional:

– A visual inspection of boiler or

process heater system

– An evaluation of operating

characteristics of the facility, specifications of energy-using systems,

operation and maintenance (O&M) procedures, and any unusual operating

constraints

– Inventory of major on-site

energy-consuming systems using energy generated by the subject boiler(s)

– Review of architectural and

engineering plans, facility O&M procedures, logs, and fuel usage

– Review of facility energy

management practices and recommendations for improvement

– List of major energy

conservation measures

– List of energy savings potential

– Report detailing ways to improve

efficiency, cost of specific improvements, benefits, and time frame for

recouping investments

There are three primary types of energy assessment. For

facilities that use less than 0.3 trillion Btu per year heat input, an 8-hour

assessment is required. Facilities using 0.3-1 trillion Btu per year heat input

require a 24-hour assessment. The boiler systems accounting for 33 percent or

more of the affected boilers’ energy output will be evaluated to identify

energy savings opportunities discovered through a 24-hour energy assessment. A

24-hour energy assessment is an energy assessment that spans 24 technical hours

of a boiler/process heater in operation at a facility. Finally, for those

facilities using over 1 trillion Btu per year heat input, a 24-hour assessment

is needed. The boiler systems accounting for 20 percent or more of the affected

boilers’ energy output will be evaluated to identify energy savings

opportunities discovered through a 24-hour energy assessment.

There are many subtleties to these

regulations, and not everything is encompassed in this article. Also, there are

slight changes for these regulations on the horizon, including the number of

exemptions that exist for boilers at certain facilities. Clarifications and

additional information will be provided in a future article in 2013.