Mechanical Insulation Design Guide

Introduction

Within This Page

- Introduction

- Design Objectives

- Condensation Control Calculator for Horizontal Pipe

- Energy Calculator for Equipment (Vertical Flat Surfaces)

- Energy Calculator for Horizontal Piping

- Mechanical Insulation Financial Calculator

- Estimated Time to Freezing for Water in an Insulated Pipe

- Personnel Protection Calculator for Horizontal Piping

- Temperature Drop Calculator for Air Ducts

- Temperature Drop Calculator for Hydronic Piping

- Other Design Considerations

Most engineers, architects, and end users are familiar with the use of insulation to reduce heating and cooling loads and to control noise in building envelopes. Insulations used for pipes, ducts, tanks, and equipment are not as familiar. The installed cost of these materials is usually a small part of the total cost of a project. As a result, mechanical insulation1 is often overlooked, undervalued, or improperly specified and maintained in commercial and industrial construction projects.

Mechanical insulation is primarily used to limit heat gain or loss from surfaces operating at temperatures above or below ambient temperature. Mechanical insulation may be used to satisfy one or more of the following design objectives (i.e., why insulate?):

- Condensation Control: minimizing condensation and the potential for mold growth by keeping the surface temperature above the dew point of the surrounding air.

- Energy Conservation – Financial Considerations: minimizing unwanted heat loss/gain from systems while minimizing the use of scarce natural resources.

- Economic Considerations – Return on Investment: maximizing return on investment and minimizing the life-cycle cost.

- Economic Thickness Considerations: considering the initial installed cost of the insulation system plus the ongoing value of energy savings over the expected service lifetime.

- Environmental Considerations – Sustainability: minimizing the emissions associated with energy usage of projects.

- Fire Safety: protecting critical building elements and slowing the spread of fire in buildings.

- Freeze Prevention: minimizing energy required for heat tracing systems and/or extending the time to freezing in the event of system failure.

- Personnel Protection – Safety: controlling surface temperatures to avoid contact burns (hot or cold).

- Process Control: minimizing temperature change in processes where close control is needed.

- Noise Control: reducing/controlling noise in mechanical systems.

In addition to these design objectives, there are a number of other design considerations that may require attention when designing a mechanical insulation system.

- Abuse Resistance

- Corrosion under Insulation

- Indoor Air Quality

- Maintainability

- Regulatory Considerations

- Service and Location

- Service Life

Designing insulation systems can be complicated, in part because they are intended to satisfy a number of design objectives. In some projects, multiple design objectives must be satisfied simultaneously. For example, the objective may be to provide the economic thickness of insulation and to avoid surface condensation on a chilled water line. The chilled water line may pass through various spaces within the project. Since the various spaces may have differing temperature and humidity conditions, it is likely that different insulation materials, thicknesses, and coverings may be required for a single line. Because projects may involve many lines, operating at different service temperatures in various environmental conditions, it is clear that a systematic approach is required for all but the simplest projects.

Design Objectives

Condensation Control

For below-ambient systems, condensation control is often the overriding design objective. The design problem is best addressed as two separate issues: 1) avoiding surface condensation on the outer surface of the insulation system, and 2) minimizing or managing water vapor intrusion.

Avoiding surface condensation is desirable for a number of reasons: 1) it prevents dripping, which can wet surfaces below; 2) it minimizes mold growth by eliminating the liquid water many molds require; and 3) it avoids staining and possible damage to exterior jacketing.

The design goal is to keep the surface temperature above the dew-point temperature of the surrounding air. Calculating surface temperature is relatively simple, but selecting the appropriate design condition is often confusing. The appropriate design condition is normally the "worst-case" condition expected for the application. For condensation control, however, a design that satisfies the worst-case condition is sometimes impossible.

To illustrate, Table 1 shows insulation thickness required to prevent condensation on the exterior surface of a hypothetical insulated tank containing a liquid held at 40°F located in a mechanical room with a temperature of 80°F. Note that at high levels of relative humidity (RH), the thickness required to prevent surface condensation increases dramatically, becoming impractical above 90% RH.

Table 1 Insulation Thickness Required to Prevent Surface Condensation

| Relative Humidity, % | Thickness, in. |

|---|---|

| 20 | — |

| 30 | 0.1 |

| 40 | 0.2 |

| 50 | 0.3 |

| 60 | 0.5 |

| 70 | 0.7 |

| 80 | 1.3 |

| 90 | 2.9 |

| 95 | 6.0 |

| Note: Calculated assuming surface conductance of 1.2 Btu/h·ft²·°F and insulation with thermal conductivity of 0.30 Btu·in/h·ft²·°F. | |

©American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc.

For outdoor applications (or for unconditioned spaces vented to outdoor air), there are always some hours per year when the ambient air is saturated or nearly saturated. At these times, no amount of insulation will prevent surface condensation. Figure 1 shows the frequency distribution of outdoor RH based on typical meteorological year weather data for Charlotte, North Carolina (Marion and Urban, 1995). Note that there are more than 1,200 hours per year when the RH is equal to or greater than 90%, and nearly 600 hours per year when the RH is equal to or greater than 95%.

Figure 1. Relative Humidity Histogram for Charlotte, North Carolina

For outdoor applications (and mechanical rooms vented to outdoor conditions), it is suggested to design for RH of 90%. Appropriate water-resistant, vapor-retarder jacketing or mastics must then be specified to protect the system from the inevitable surface condensation.

Table 2 summarizes design weather data for a select number of cities. The design dew-point temperature and the corresponding dry-bulb temperatures at 90% RH are given, along with the number of hours per year that the RH would exceed 90%. Additional design dew-point data can be found in the Climatic Design Information chapter of the ASHRAE Handbook—Fundamentals (www.ashrae.org).

Table 2. Design Weather Data for Condensation Control

| City | Design Dew-Point Temp., °F | Corresponding Dry-Bulb Temp at 90%RH, °F |

Hours per Year >90%RH |

|---|---|---|---|

| New Orleans, LA | 79 | 82 | 1,253 |

| Houston, TX | 78 | 81 | 2,105 |

| Miami, FL | 78 | 81 | 633 |

| Tampa, FL | 78 | 81 | 992 |

| Savannah, GA | 77 | 80 | 1,560 |

| Norfolk, VA | 76 | 79 | 1,279 |

| San Antonio, TX | 76 | 79 | 932 |

| Charlotte, NC | 74 | 77 | 1,233 |

| Honolulu, HI | 74 | 77 | 166 |

| Columbus, OH | 73 | 76 | 531 |

| Minneapolis, MN | 73 | 76 | 619 |

| Seattle, WA | 60 | 63 | 1,212 |

Design Example: Tampa, Florida

Chilled water supply piping is to be located outdoors to serve a commercial building expansion in Tampa, Florida. The supply piping is 6" NPS steel, and the design temperature of the chilled-water supply is 40°F. It is desired to determine the appropriate design ambient conditions for this installation. Referring to Table 2 (or to the appropriate design dew-point data from the ASHRAE Handbook), we see that the design dew-point temperature for Tampa is 78°F.

The design conditions are best visualized using a psychrometric chart. A psychrometric chart graphically represents the properties of moist air. The horizontal axis of the chart is dry-bulb temperature. The vertical axis is humidity ratio (lbs. of water vapor per lb. of dry air). The chart includes the saturation curve (RH = 100%) as well as parallel curves for other values of constant RH. Lines of constant dew-point temperature are horizontal on the psychrometric chart.

Using the ASHRAE psychrometric chart (see Figure 2), we enter the chart on the saturation curve at a dew point of 78°F (point A in the figure) and draw a horizontal line. Our design point is located where this horizontal line intersects the 90% RH curve (labeled Design Point in the figure). The dry-bulb temperature associated with this design point is read from the horizontal axis at point C, which for this example is approximately 81°F. The insulation system will therefore be designed for an operating temperature of 40°F, an ambient temperature of 81°F, and an ambient RH of 90%.

Figure 2: ASHRAE Psychrometric Chart No. 1

©American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc.

For indoor designs in conditioned spaces, care must still be exercised when selecting the design conditions. Often, the HVAC system will be sized to provide indoor conditions of 75°F/50% RH on a design summer day. However, those indoor conditions would not represent the worst-case indoor conditions with respect to the insulation design. Part-load conditions could result in higher humidity levels, or night and/or weekend shutdown could result in more severe conditions.

Note that the discussion here has focused so far on designing to avoid condensation on the exposed surface. Another important design consideration is minimizing or managing water vapor intrusion. Water vapor intrusion is extremely important for piping and equipment operating at below-ambient temperatures. Water-related problems include thermal performance loss, health and safety issues, structural degradation, and aesthetic issues. Water entry into the insulation system may be through diffusion of water vapor, air leakage carrying water vapor, and leakage of surface water.

During those periods when the operating temperature is below the dew point of the surrounding ambient air, there will be a difference in water vapor pressure across the insulation system. This vapor pressure difference serves as the driving force for diffusion of water vapor from the ambient toward the cold surface. Piping and equipment typically create an absolute barrier to the passage of water vapor, so any vapor pressure difference imposed across the insulation system results in the potential for condensation either within the insulation or at the cold surface. The vapor pressure difference can range from below 0.1" Hg (0.05 psi) for a supply-air duct operating in the return-air plenum of a commercial building to 1.2" Hg (0.6 psi) for a cryogenic system operating outdoors near the U.S. Gulf Coast. While these pressure differences seem small, the impact over many operating hours can be significant.

There are a number of fundamental design principles utilized in managing water vapor intrusion. One method is to reduce the driving force by reducing the moisture content of the surrounding air. While the insulation designer will typically not have control of the location of the piping, ductwork, or equipment to be insulated, there are opportunities for the mechanical engineer to influence the ambient conditions. Certainly, locating cold piping, ductwork, and equipment in unconditioned portions of buildings should be minimized. Consideration should be given to conditioning mechanical rooms, if feasible.

Another common method is the application of moisture blocking design. The moisture blocking principle is applied in a design wherein the passage of water vapor is eliminated or minimized to an insignificant level. The design must incorporate the following: 1) a vapor retarder with suitably low permeance; 2) a joint-and-seam sealing system that maintains vapor retarding system integrity; and 3) accommodation for future damage repair, joint and seam resealing, and reclosing after maintenance.

A vapor retarder is a material or system that will adequately reduce the transmission of water vapor through the insulation system. The vapor retarder system is seldom intended to resist the entry of surface water or prevent air leakage but can occasionally be considered the second line of defense for these moisture sources.

A high-quality vapor retarder material or system is essential for blocking systems to perform adequately. Research (Mumaw, 2001) has shown that the design, installation, and performance of the vapor retarder systems are key to the ability of an insulation system to minimize water vapor ingress. The performance of the vapor retarder material or system is characterized by the water vapor permeance. The lower the water vapor permeance the better. The water vapor permeance can be evaluated using standard procedures outlined in ASTM Standard Test Method E96. In this test, a vapor pressure difference is imposed across the vapor retarder material that has been sealed to a test cup, and the moisture gain or loss is measured gravimetrically.

Faulty application techniques can impair vapor retarder performance. The effectiveness of installation and application techniques must be considered when selecting a vapor retarder system. Factors such as vapor retarder structure, number of joints, mastics and adhesives used, as well as inspection procedures will impact the performance and durability of the vapor retarder system.

The insulation system should be dry prior to the application of a vapor retarder to prevent trapping water vapor within the insulation system. The insulation system must be protected from undue weather exposure that could introduce moisture into the insulation before the system is sealed.

When selecting a vapor retarder, the vapor pressure difference across the insulation system should be considered. Higher vapor pressure differences typically require a vapor retarder that that has a lower permeance to control the overall moisture pickup of the insulated system. The service conditions impact the direction and magnitude of the vapor pressure difference. Unidirectional flow exists when the water vapor pressure is constantly higher on one side of an insulation system. Reversible flow exists when vapor pressure may be higher on either side. This is typically due to diurnal or seasonal changes on one side of the insulation system. The properties of the insulating materials used for the insulation system should be considered. All materials reduce the flow of water vapor; the low permeance of some insulations can add to the overall resistance to water vapor transport of the insulation system. Some low-permeability insulation materials are considered to be vapor retarders without any additional jacket material.

Another fundamental design principle is the moisture storage design. In many systems, some condensation can be tolerated, with the amount depending on the water-holding capacity or water tolerance of a particular system. The moisture storage principle permits accumulation of water in the insulation system but at a rate designed to prevent harmful effects. This concept is applicable when: 1) unidirectional vapor flow occurs, but accumulations during severe conditions can be adequately expelled during less severe conditions; or 2) reverse-flow conditions regularly occur on a seasonal or diurnal cycle. Design solutions using this principle include: 1) periodically flushing the cold side with low dew point air (this procedure requires a supply of conditioned air and a means for distribution), and 2) use of an insulation system supplemented by selected vapor retarders and absorbent materials such that an accumulation of condensation is of little importance. Such a design must ensure that the expulsion of the accumulation is adequate.

ASTM Standard Practice C 755 Selection of Water Vapor Retarders for Thermal Insulation, contains a discussion of various design principles. The ASHRAE Handbook—Fundamentals (www.ashrae.org) has a thorough description of the physics associated with water vapor transport in Chapters 23–26. Additional information is found in Chapter 10 of the ASHRAE Handbook—Refrigeration. Another excellent reference is the ASTM manual Moisture Analysis and Condensation Control in Building Envelopes (www.astm.org).

Energy Conservation - Financial Considerations

Thermal insulation is commonly used to reduce the rate of unwanted heat loss/gain from/to mechanical systems and equipment. There are three primary reasons:

- To minimize the usage of scarce natural resources,

- To minimize the emissions associated with energy usage, and

- To maximize return on investment and minimize the life-cycle costs of projects.

While the source of our energy has changed over of the years, as well our dependency on foreign energy sources, the focus on the need for energy conservation has not. Energy supply and demand plays an increasingly vital role in national security and the economy.

Energy conservation efforts gained momentum as a result of the energy shortages in the early 1970s. The ASHRAE Standard 90-75, Energy Conservation in New Building Design, approved in 1975, became the basis for various building energy codes. This standard has evolved into the current ASHRAE Standards 90.1 (Energy Standard for Buildings Except Low-Rise Residential Buildings) and 90.2 (Energy Efficient Design of Low-Rise Residential Buildings). ASHRAE Standard 90.1 has been adopted by reference in the International Energy Conservation Code (IECC).

Minimum insulation levels for ductwork and piping are often dictated by these energy standards, which are often adopted by model building code organizations and/or various jurisdictions as building energy codes. These energy codes address energy conservation in buildings but typically do not address additional design objectives (such as condensation control, personnel protection, or noise control) that may be important on a specific project. The adoption of energy codes varies by state and locality, and the level of enforcement varies. The model energy codes are typically updated on a 3-year cycle, and various versions are enforced differently in each respective jurisdiction. For the current status of statewide energy codes, see www.bcap-energy.org or www.energycodes.gov.

Some states and local jurisdictions are going beyond the baseline energy codes and adopting alternative codes in the interest of energy efficiency and sustainability. These are sometimes referred to as Green Building Codes, "stretch" codes, or beyond code programs. Most of these programs use the ASHRAE 90.1 or the IECC as a baseline. They vary widely in scope. Key examples include the ASHRAE Standard 189 and the International Green Construction Code (IgCC).

Energy standards for industrial facilities have not been developed. Efforts to develop consensus on industrial standards or guidelines are complicated by: 1) the wide variety of industrial facilities, 2) the perception that importance of insulation is small compared to the other energy consuming systems, and 3) the general misconception of the value provided by mechanical insulation.

As a part of efforts by the Department of Energy's (DOE) Advanced Manufacturing Office (AMO) to improve the energy efficiency of the U.S. industrial and commercial sectors, the National Insulation Association (NIA), worked to design and launch a mechanical insulation energy calculator. As an aid to understanding the relationships between energy, economics, and emissions for insulated systems, simple spreadsheet calculators have been developed for equipment, vertical flat surfaces, and horizontal pipe applications.

The algorithms used in these energy calculators are based on the calculation methodologies outlined in ASTM C680, Standard Practice for Estimate of the Heat Gain or Heat Loss and the Surface Temperatures of Insulated Flat, Cylindrical, and Spherical Systems by Use of Computer Programs. The ASTM C680 standard is routinely used for predicting the heat loss or gain and surface temperatures of certain thermal insulation systems that can attain one-dimensional, steady- or quasi-steady-state heat transfer conditions in field operations. Users are encouraged to review the Scope and Significance and Use sections of this standard.

The equipment spreadsheet estimates the heat flows through a vertical, flat, steel surface (typical of the sides of a large steel tank containing a heated or cooled fluid). Information concerning a hypothetical insulation system (e.g., the area, operating temperature, ambient temperature and wind speed, insulation material, and surface emittance of the proposed insulation system) may be input by the user. Calculated results are given over a range of insulation types and thicknesses. They include: 1) surface temperature, 2) heat flow, 3) annual cost of fuel, 4) payback period, 5) annualized rate of return, and 6) annual CO2 emissions.

The pipe spreadsheet estimates the heat flows through horizontal piping. Information concerning a hypothetical insulation system (e.g., the length of run, pipe size, operating temperature, ambient temperature and wind speed, insulation material, and surface emittance of the proposed insulation system) may be input by the user. Calculated results are given over a range of insulation types and thicknesses and include 1) surface temperature, 2) heat flow, 3) annual cost of fuel, 4) payback period, 5) annualized rate of return, and 6) annual CO2 emissions.

Other geometries and more complex insulation systems may be analyzed using publicly available software such as the 3E Plus® program. 3E Plus was developed by the North American Insulation Manufacturers Association (NAIMA) and is available at www.pipeinsulation.org.

Economic Considerations - Return on Investment

Insulation systems are frequently designed with the objective of minimizing costs. Properly designed insulation systems can reduce heat loss (or gains) from (or to) mechanical systems by 90–98%. When energy must be purchased to offset these heat flows, insulation systems can quickly pay for themselves in reduced energy costs.

Insulation projects (like many energy-conservation projects) generally involve making an initial investment that will result in future cost savings. A number of approaches can be used to measure the financial desirability of an insulation project. All require estimates of the initial investment (the installed cost of the insulation system) and the resulting future savings. Some of these financial measures are simple, like Return on Investment (ROI) and Simple Payback Period (PP). Others are more complicated and take into account the time value of money, inflation, and taxes.

In today’s economic environment, companies are requiring that investments be subject to review at various levels in the approval process. The Mechanical Insulation Financial Calculator was developed to provide a simple example of specific financial measures related to investments in mechanical insulation. It can be used for an overall mechanical insulation project or simply for a small mechanical insulation investment, such as insulating a valve or replacing a section of insulation. Tax implications of the investment have not been considered in the Mechanical Insulation Financial Calculator. You should consult your financial advisor for specific and/or tailored financial calculations. The following definitions are provided for reference purposes.

Return on Investment. The ROI is simply the estimated annual return (savings) divided by the initial investment (installed cost) expressed as a percentage. If the estimated installed cost of an insulation system is $10,000 and the annual savings are expected to average $5,000 per year, the ROI for the project would be 50%. The higher the ROI, the better. In equation form #1:

| FYS | ||

| ROI = | ——— | x 100% |

| FC |

where:

FYS = First-Year Savings due to the insulation system ($/yr.)

FC = First (installed) Cost of the insulation system ($)

Simple Payback Period. PP is the number of years it will take to recover the initial installed cost, or investment, based on the estimated annual savings. PP is calculated as the initial investment divided by the first-year savings. Using the same example from above, if the estimated installed cost of an insulation system is $10,000, and the savings are expected to be $5,000 per year, the PP for the project would be 2 years. The PP is compared to the expected life of the investment to judge acceptability. The shorter the PP, the better.

In equation form:

| FC | |

| PP = | ——— |

| FYS |

where:

FC = First (installed) Cost of the insulation system ($)

FYS = First-Year Savings due to the insulation system ($/yr.)

Neither the ROI nor the PP takes into account the time value of money. The time value of money is simply a recognition that a dollar in hand today is worth more than a dollar received a year from now, due to the opportunity to earn compound interest. Suppose we place $100 in a savings account that earns 4% interest, compounded annually. At the end of the first year, we have earned 4% (or $4) on our initial deposit of $100, giving us $104 in our account. Put another way, the present value of a cash flow of $104 received a year from now is $100 today. The future value ($104) is discounted to the present value ($100) using an interest rate (also called the discount rate). The simple concept of discounted cash flow is central to a number of methods of financial analysis. These methods take into account both the magnitude and the timing of expected cash flows in each period of a project's life. Two frequently used methods are the Net Present Value (NPV) and the Internal Rate of Return (IRR).

NPV is the difference between the present value of cash inflows and the present value of cash outflows. With the NPV method, all cash flows are discounted to the present value using the discount rate. If the NPV is positive, the project should be acceptable; if it is not, it may be rejected from a financial perspective. The method requires selection of an appropriate discount rate, sometimes referred to as the "hurdle rate" or the "required rate of return." It should be established as equal to the highest rate of return available on alternative investments of comparable risk or a company-established minimum threshold.

The NPV of an example insulation project is illustrated in Figure 3. The example assumes an initial installed cost of insulation of $10,000 and estimated first-year savings of $5,000, with a 20-year economic life. Fuel cost escalation is assumed to be 3% per year. The discount rate, or hurdle rate, is assumed to be 5% for this example. The NPV of this project would be nearly $70,000 over the 20-year life.

Fig. 3 Cumulative Discounted Cash Flow vs. Time

Assumptions:

- Initial Insulation Investment = $10,000

- First-Year Energy Cost Savings = $5,000

- Energy Cost Escalation Rate = 3%

- Estimated Economic Life = 20 Years

- Discount Rate = 5%

The Internal Rate of Return (IRR) is defined as the discount rate that makes the NPV of all cash flows (both positive and negative) from an investment equal to zero. In other words, the IRR of an investment is the interest rate at which the NPV of costs equals the NPV of the benefits of the investment. If the IRR is greater than the firm's hurdle rate, the project should be acceptable. The higher the IRR, the more desirable the investment.

Economic Thickness Considerations

The concept of economic thickness of insulation considers the initial installed cost of the insulation system plus the ongoing value of energy savings over the expected service lifetime. The economic thickness is defined as the thickness that minimizes the total life-cycle cost (see Figure 4). The installed costs (labor and material) of the insulation increase with thickness. Insulation is often applied in multiple layers 1) because materials are not manufactured in single layers of sufficient thickness, 2) to accommodate expansion and contraction of insulation and system components, and 3) to minimize thermal short circuits at joints. Figure 4 shows initial installed costs for a multilayer application. The curve is discontinuous and increases with the number of layers because labor and material costs increase more rapidly as thickness increases. Figure 4 also shows the present value of the "lost energy" cost over the expected life of the project, which decreases as the insulation thickness is increased. The total cost curve, which is the sum of the installed insulation cost and the present value of the lost energy cost curves, shows a minimum value at Point A. This point on the total cost curve corresponds to the economic insulation thickness, which in this example is in the double-layer range.

Initially, as insulation is applied, the total life-cycle cost decreases rapidly because the value of incremental energy savings is greater than the incremental cost of insulation. Additional insulation reduces total cost up to a thickness where the change in total cost is equal to zero. At this point, no further reduction can be obtained; beyond it, incremental insulation costs exceed the additional energy savings derived by adding another increment of insulation.3

An economic thickness analysis should consider the time value of money, which can be based on a desired rate of return for the insulation investment. Energy costs are volatile, and a fuel cost inflation factor is sometimes included to account for the possibility that fuel costs may increase more quickly than general inflation. Insulation system maintenance costs should also be included, along with any identifiable cost savings associated with the ability to specify lower capacity equipment.

Figure 4. Economic Thickness of Insulation

It should be noted that any economic analysis must, by nature, deal with quantifiable benefits and costs. Some benefits (e.g., thermal comfort of occupants, increased life of mechanical equipment, reduced dependency on energy imports, and reduced emissions) are difficult to quantify. Designers should therefore consider the economic thickness of insulation to be a minimum.

Economic considerations also come into focus during the owner/contractor "value engineering" (VE) process. Efforts by the contractor or owner/developer to reduce the initial cost of a building or structure by applying the principles of VE to the design and construction of the building must be carefully weighed by the architect/engineer-of-record against the long-term interests of the owner/end-user. This is particularly true with regard to mechanical insulation. In too many instances, the term "value engineering" is used as a euphemism for cost reduction. Design choices of insulation materials, thicknesses, and jacketing systems made by the design professional are arbitrarily considered cost-prohibitive on a project and are eliminated during the VE process. In some cases, the costs associated with correcting problems arising from decisions made during the VE process can be significant, and the work highly disruptive. The importance of documenting the criteria utilized in the design and highlighting these criteria during the VE process is emphasized.

Environmental Considerations: Sustainability

In conjunction with the benefits associated with conserving energy resources, insulation contributes to the reduction in emissions associated with using those energy resources. Since fossil fuels are the primary source of energy in developed countries, a reduction in energy use will translate into a reduction in emissions from the burning of fossil fuels. The primary products of combustion of fossil fuel are carbon dioxide and water vapor. Both are considered greenhouse gases.

Concerns over rising levels of carbon dioxide and other greenhouse gases in our atmosphere have focused attention on the process of global climate change and the degree that human activity is influencing climate change (www.epa.gov/climatechange). Greenhouse gases are components of the atmosphere that contribute to the greenhouse effect. Some greenhouse gases occur naturally in the atmosphere, while others result from human activities. Naturally occurring greenhouse gases include water vapor, carbon dioxide, methane, nitrous oxide, and ozone. Certain human activities, however, add to the levels of most of these naturally occurring gases.

Different greenhouse gases have differing global warming potential (GWP). GWP is a measure of how much a given mass of greenhouse gas is estimated to contribute to global warming. It is a relative scale that compares the gas in question to that of the same mass of carbon dioxide (whose GWP is, by definition, 1.0). This definition enables a method for accounting for greenhouse gas emissions known as "Carbon Dioxide Equivalent" (or CO2e). The CO2e may be used to compare the emissions from various greenhouse gases based upon the amount of carbon dioxide that would have the same global warming potential (GWP), measured over a specified timescale (generally, 100 years). Carbon dioxide equivalents (CDE) are commonly expressed:

- In industry as million metric tons of carbon dioxide equivalents (MMTCDE).

- In vehicles as g of CDE/km (gCDE/km).

The CDE for a gas is derived by multiplying the mass of the gas by the associated GWP. Methane has a GWP of 23.

Extending this concept, greenhouse gas emissions are sometimes expressed in terms of "carbon equivalent" (or CE). This is simply the CO2e multiplied by the amount of carbon per molecule of carbon dioxide (= 12/44 = 0.2727).

Table 3. Carbon Equivalents for Various Greenhouse Gases

| Gas | Formula | Carbon Equivalent per lb |

|---|---|---|

| Carbon Dioxide | CO2 | 0.2727 |

| Methane | CH4 | 6.27 |

| Nitrous Oxide | N2O | 80.7 |

| CFC-11 | CCl3F | 1,250 |

| HFC-23 | CHF3 | 3,270 |

| Sulfur Hexafluoride | SF6 | 6,050 |

A number of pollutants are currently regulated by federal and state clean air regulations (NOx, SO2, CO, and particulates).

Interest in sustainability and green buildings (i.e., the consideration of environmental responsibility and energy efficiency as key issues in building design) is increasing. The LEED (Leadership in Energy and Environmental Design) Green Building Rating System, created by the U.S. Green Building Council (www.usgbc.org), is a voluntary rating system that sets out sustainable design and performance criteria for buildings. It evaluates environmental performance from a whole-building perspective and awards points based on satisfying performance criteria in several different categories. Different levels of green building certification are awarded based on the total points earned. U.S. federal agencies have committed to sustainable building design through adoption Federal Leadership in High Performance and Sustainable Buildings Memorandum of Understanding (MOU).

Architecture 2030 (www.architecture2030.org) partners with policymakers from local governments and stakeholders across the United States and international markets to analyze and accelerate the adoption of critical zero net carbon (ZNC) emissions policies in new construction and existing buildings. ASHRAE has adopted a position statement supporting building sustainability as a means to provide a safe, healthy, comfortable indoor environment while simultaneously limiting the impact on the earth's natural resources.

Mechanical insulation contributes to sustainability primarily by reducing energy usage and the associated greenhouse gas emissions. Insulation products are one of the few types of building materials considered to be "carbon negative," in that reductions in carbon emissions over the life of the material far exceed the carbon emissions associated with its manufacture, transport, and installation (Russell, 2007). In addition, well-insulated mechanical systems can often result in smaller sized equipment, which also contributes to sustainability.

As an aid to understanding the relationship between energy, economics, and emissions for insulated systems, a simple spreadsheet calculator was developed and is included within the previous Design Objectives, Economic Thickness Considerations.

Fire Safety

Fire safety is a common design objective. Mechanical insulation materials are often used as a component in systems or assemblies designed to protect buildings and equipment from the effects or spread of fire (i.e., fire-resistance assemblies). They can include walls, roofs, floors, columns, beams, partitions, ducts, joints, and through-penetration fire stops. As an example, insulation products are often used as an alternative to fire resistance-rated shaft enclosures in applications like kitchen exhaust grease ducts, ventilation ducts, stairwell pressurization ducts, smoke extraction, chemical fume exhaust ducts, and refuse and trash chutes.

Specific designs are tested and assigned hourly ratings based on performance in full-scale fire tests. Note that insulation materials alone are not assigned hourly fire-resistance ratings; ratings are assigned to a system or assembly that may include specific insulation products along with other elements such as framing members, fasteners, wallboard, etc.

Fire-resistance ratings are often developed using ASTM E119. This test exposes assemblies (walls, partitions, floor or roof assemblies, and through-penetration fire stops) to a standard fire controlled to achieve specified temperatures throughout a specified time period. The time-temperature curve is intended to be representative of building fires where the primary fuel is solid, and it specifies a temperature of 1,000°F at 5 minutes, 1,700°F at 1 hour, and 2,300°F at 8 hours. In the hydrocarbon processing industry, liquid hydrocarbon-fueled pool fires are a concern; fire-resistance ratings for these applications are tested per ASTM E1529. This time-temperature curve rises rapidly to a temperature of 2,000°F within 5 minutes and remains there for the duration of the test.

Fire resistance-rated designs can be found in the directories of listing agencies. Examples of such not-for-profit agencies include Underwriters Laboratories, Factory Mutual, and UL Canada.

When fire safety is not a design objective, it is often still a design consideration. Materials used to insulate mechanical equipment generally must meet the requirements of local codes adopted by government entities having jurisdiction over the project. In the United States, most local codes incorporate or are patterned after model codes developed and maintained by organizations such as the National Fire Protection Association (NFPA) and the more recent International Code Council (International Codes). Refer to local codes to determine specific requirements.

Most codes related to insulation product fire safety refer to the surface burning characteristics as determined by the Steiner tunnel test (ASTM E84, NFPA 255, UL 723, or CAN/ULC S-102). These similar test methods evaluate the flame spread and smoke developed from samples mounted in a 25 foot-long tunnel and subsequently exposed to a controlled flame. Results are given in terms of flame spread and smoke developed indices, which are relative to a baseline index and calibration standards of inorganic reinforced cement board (0) and select grade red oak flooring (100). Samples are normally mounted with the exposed surface face down in the ceiling of the tunnel. Upon ignition, the progress of the flame front is timed while being tracked visually for distance down the tunnel, with the results used to calculate the flame spread index. Smoke index is determined by measuring smoke density with a light cell mounted in the exhaust stream.

Using supporting materials on the underside of the test specimen can lower the flame spread index. Materials that melt, drip, or delaminate to such a degree that the continuity of the flame front is destroyed give low flame spread indices that do not relate directly to indices obtained by testing materials that remain in place. Alternate means of testing may be necessary to fully evaluate some of these materials.

For pipe and duct insulation products, samples are prepared and mounted in the tunnel per ASTM E2231, which directs that "the material, system, composite, or assembly tested shall be representative of the completed insulation system used in actual field installations, in terms of the components, including their respective thicknesses." Samples are constructed to mimic the products as they will be used as closely as possible, including any facings and adhesives, as appropriate.

Duct insulation generally requires a flame spread index of not more than 25 and a smoke developed index of not more than 50 when tested in accordance with ASTM E84. Codes often require factory-made duct insulations (e.g., insulated flexible ducts, rigid fibrous glass ducts) to be listed and labeled per UL 181, Factory-Made Air Ducts and Air Connectors. This standard specifies a number of other fire tests (e.g., flame penetration and low-energy ignition) as part of the listing requirements.

Some building codes require that duct insulations meet the fire hazard requirements of NFPA 90A or 90B to restrict spread of smoke, heat, and fire through duct systems; and to minimize ignition sources. Local code authorities also should be consulted for specific requirements.

For pipe insulation, the requirement is generally a maximum flame spread index of 25 and a maximum smoke developed index of 450. For insulation materials exposed within supply and return ducts and plenums, the typical requirement is that the materials be noncombustible or have a maximum flame spread index of 25 and a maximum smoke developed index of 50. Consult local code authorities for specific requirements.

The term “noncombustible,” as defined by building codes, refers to materials that pass the requirements of ASTM Standard E136. This test method involves introducing a small specimen of the material into a furnace initially maintained at a temperature of 1,380°F. The temperature rise of the furnace is monitored, and the specimen is observed for any flaming. Criteria for passing include limits on temperature rise, flaming, and weight loss of the specimen. Some building codes accept as noncombustible a composite material having a structural base of noncombustible material and a surfacing not more than 1/8-inch thick that has a flame spread index not greater than 50. A related term sometimes referenced in building codes is “limited combustible,” which is an intermediate category that considers the potential heat content of materials determined per the testing requirements of NFPA Standard 259.

Freeze Prevention

It is important to recognize that while insulation retards heat flow, it does not stop it completely. If the surrounding air temperature remains low enough for an extended period, insulation cannot prevent freezing of still water or of water flowing at a rate insufficient for the available heat content to offset heat loss. Clean water in pipes usually supercools several degrees below freezing before any ice is formed. Then, upon nucleation, ice forms in the water and the temperature rises to freezing. Ice can be formed from water only by the release of the latent heat of fusion (144 Btu/lb.) through the pipe insulation. Well-insulated pipes may greatly retard this release of latent heat. Gordon (1996) showed that water pipes burst not because of ice crystal growth in the pipe, but because of elevated fluid pressure within a confined pipe section occluded by a growing ice blockage.

Insulation can prolong the time required for freezing or prevent freezing if flow is maintained at a sufficient rate. To calculate time θ (in hours) required for water to cool in a pipe with no flow, use equation #3 below:

where

θ = time to freezing, h

ρ = density of water = 62.4 lb./ft3

Cp = specific heat of water = 1.0 Btu/lb.·°F

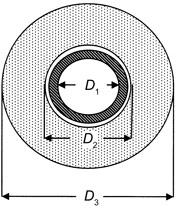

D1 = inside diameter of pipe, ft (see Figure 5)

L = length of pipe, ft

RT = combined thermal resistance of pipe wall, insulation, and exterior air film, h·°F/Btu

ti = initial water temperature, °F

ta = ambient air temperature, °F

tf = final temperature, 32°F for water

As a conservative assumption for insulated pipes, thermal resistances of pipe walls and exterior air film are usually neglected. In equation #4 below, resistance of the insulation layer for a pipe is calculated as:

where

RT = thermal resistance of the insulation layer, h·°F /Btu

D3 = outer diameter of insulation, ft

D2 = inner diameter of insulation, ft

k = thermal conductivity of insulation material, Btu·in/(h·ft2·°F)

L = length of pipe, ft

12 = conversion factor, in/ft

Figure 5. Time to Freeze Nomenclature

©American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc.

Table 4 shows estimated time to freezing, calculated using these equations for the specific case of still water, with ti = 42°F and ta = -18°F.

Table 4. Time to Cool Water to Freezing, h

| Nominal Pipe Size, NPS | Insulation Thickness, in. | |||||

|---|---|---|---|---|---|---|

| 0.5 | 1 | 1.5 | 2 | 3 | 4 | |

| 1/2 | 0.1 | 0.2 | 0.2 | 0.3 | — | — |

| 1 | 0.3 | 0.4 | 0.5 | 0.6 | 0.8 | — |

| 1 1/2 | 0.4 | 0.8 | 1.0 | 1.3 | 1.5 | — |

| 2 | 0.6 | 1.1 | 1.4 | 1.7 | 2.2 | 2.5 |

| 3 | 0.9 | 1.7 | 2.3 | 2.9 | 3.7 | 4.5 |

| 4 | 1.3 | 2.4 | 3.3 | 4.1 | 5.5 | 6.6 |

| 5 | 1.6 | 3.0 | 4.3 | 5.4 | 7.4 | 9.1 |

| 6 | 1.9 | 3.7 | 5.3 | 6.9 | 9.4 | 11.7 |

| 8 | — | 5.3 | 7.6 | 9.6 | 13.7 | 16.9 |

| 10 | — | 6.5 | 10.2 | 12.9 | 17.9 | 22.3 |

| 12 | — | 8.8 | 12.5 | 15.8 | 22.1 | 27.7 |

| Note: Assumes initial temperature = 42°F, ambient air temperature = -18°F, and insulation thermal conductivity = 0.30 Btu·in/h·ft²·°F. Thermal resistances of pipe and air film are neglected. | ||||||

©American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc.

When unusual conditions make it impractical to maintain protection with insulation or flow, a hot trace pipe or electric resistance heating cable is required. The heating system then supplies the heat lost through the insulation.

The consequences of frozen pipes extend beyond the cost of directly related repairs. The cost of shutting down and restarting a plant, a manufacturing facility, or business—and the resulting loss of revenue—easily can exceed the cost of repairs.

Personnel Protection and Safety

In many applications, insulation is provided to protect personnel from burns. In addition, there are safety and comfort concerns related to personnel working in high-temperature, high radiant exposure locations.

The potential for burns to human skin is a complex function of surface temperature, surface material, and time of contact. ASTM standard guide C1055 has a good discussion of these factors. ASTM standard practice C1057 provides a mathematical model for determination of skin contact temperature from heated surfaces. Standard industry practice is to specify a maximum temperature of 140°F for surfaces that may be contacted by personnel. This temperature would cause no more than first-degree burns for all surfaces for contact times up to about 5 seconds. Note that for non-industrial settings (e.g., retail stores), it may be prudent to design for longer contact times (i.e., using lower surface temperatures).

When evaluating an insulation system for the potential for burn hazards, select the appropriate worst-case ambient condition. For indoor applications, maximum air temperatures depend on the facility and location, and they are typically lower than design outdoor conditions. For outdoor installations, base calculations on summer design ambient temperatures with no wind (i.e., the worst case). Surface temperatures increase because of solar loading but are usually neglected because of variability in orientation, solar intensity, and many other complicating factors. Engineering judgment must be used in selecting ambient and operating temperatures and wind conditions for these calculations.

Note that the choice of jacketing strongly affects a surface's relative safety. Higher-emittance jacketing materials (e.g., plastic, painted metals) can be selected to minimize the surface temperature. Jacketing material also affects the relative safety at a given surface temperature. For example, at 175°F, a stainless-steel jacket blisters skin more severely than a nonmetallic jacket at equal contact time.

Process Control

Insulation systems are often designed to minimize variation of temperatures in processes. A common example is the use of insulation on tanks or vessels used as chemical reactors where the yield of the reaction is dependent on the temperature. Insulating the reactor helps to isolate the reaction from variations in ambient temperature and minimizes the capability of these variations to affect process heating and/or cooling equipment.

Another example is the use of insulation to minimize temperature change (either temperature drop or rise) of a fluid from one location to another. Consider the case of a hot fluid flowing down a pipe or duct. The temperature drop of the fluid may be calculated by using equation #5:

where

Ti = initial (entering) fluid temperature, °F

Tf = final (leaving) fluid temperature, °F

Ta = ambient temperature, °F

U = overall heat transfer coefficient, Btu/(hr·ft²·°F)

P = outside perimeter of pipe or duct, ft

L = length of pipe or duct run, ft

m = flow rate of fluid, lbm/hr.

Cp = specific heat of fluid, Btu/(lbm·°F)

Note that for a cold fluid flowing down a pipe, the temperature drop will have a negative sign, which indicates a temperature rise in the fluid stream.

Noise Control

Insulation is often specified on mechanical systems and equipment to control noise within buildings and other facilities.

Noise radiating from pipes. Noise from piping can be reduced by adding an absorptive insulation and jacketing material. By knowing the sound insertion loss of insulation and jacketing material combinations, the expected level of noise reduction in the field can be estimated. A range of jacket weights and insulation thicknesses can be used to reduce noise. Jackets used to reduce noise are typically referred to as being mass-filled. Some products for outdoor applications use mass-filled vinyl (MFV) in combination with aluminum.

Pipe insertion loss is a measurement (in decibels, dB) of the reduction in sound pressure level from a pipe as a result of the application of insulation and jacketing. Measured at different frequencies, the noise level from the jacketed pipe is subtracted from that of the bare pipe. The larger the insertion loss number, the larger the amount of noise reduction.

ASTM Standard E1222 describes how to determine insertion loss of pipe jacketing systems. A band-limited white noise test signal is produced inside a steel pipe located in a reverberation room, using a loudspeaker or acoustic driver at one end of the pipe to produce the noise. Average sound pressure levels are measured in the room for two conditions: 1) with sound radiating from a bare pipe, and 2) with the same pipe covered with a jacketing system. The insertion loss of the jacketing system is the difference in the sound pressure levels measured, adjusted for changes in room absorption caused by the jacketing system's presence. Results may be obtained in a series of 100 Hz-wide bands or in one-third octave bands from 500 to 5,000 Hz.

Table 5 gives measured insertion loss values for several pipe insulation and jacket combinations. The weight of the jacket material significantly affects insertion loss of pipe insulation systems. Figure 6 shows insertion loss of typical fibrous pipe insulations with various weights of jacketing (Miller 2001).

Table 5. Insertion Loss for Pipe Insulation Materials, dB

| Pipe Size, NPS | Insulation Material | Insulation Thickness, in. |

Jacket | Frequency, Hz | |||

|---|---|---|---|---|---|---|---|

| 500 | 1000 | 2000 | 4000 | ||||

| 6 | Fibrous glass

Flexible elastomeric |

2

4 0.5 |

ASJ 0.020 in. aluminum 1 lb/ft² MFV with Al ASJ 0.020 in. aluminum None1 lb/ft² MFV with Al |

2 3 13 4 3 0 0 0 0 |

9 16 20 21 17 2 2 14 16 |

14 24 32 27 27 5 5 18 20 |

16 33 40 33 42 10 10 20 26 |

| 12 | Fibrous glass

Mineral Wool |

2

4 2 |

ASJ 0.020 in. aluminum ASJ 0.020 in. aluminum 1 lb/ft² MFV with Al 0.016 in. aluminum |

0 4 8 12 14 1 0 |

12 19 16 22 23 9 14 |

19 25 22 30 31 18 19 |

23 26 26 32 31 28 30 |

©American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc.

Figure 6. Insertion Loss Versus Weight of Jacket

©American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc.

It is important that sound sources be well identified in industrial settings. It is possible to treat noisy sources effectively and have no significant influence on ambient sound measurement after treatment. It also is important that all sources of noise above desired levels receive acoustical treatment, beginning with the largest source, or no improvement will be observed.

Noise from ducts. HVAC ducts act as conduits for mechanical equipment noise, and they carry office noise between occupied spaces. Additionally, some ducts can create their own noise through duct wall vibrations or expansion and contraction. Lined sheet metal ducts and fibrous glass rigid ducts can greatly reduce transmission of HVAC noise through the duct system. The insulation also reduces crosstalk from one room to another through the ducts.

Attenuation loss is noise absorbed within the duct. In uninsulated ducts, it is a function of duct geometry and dimensions, as well as noise frequency. Internal insulation liners are generally available for most duct geometries. In the ASHRAE Handbook—HVAC Applications provides attenuation losses for square, rectangular, and round ducts lined with fibrous glass, and it gives guidance on the use of insulation in plenums to absorb duct system noise. Internal linings can be very effective in fittings such as elbows, which can have two to eight times more attenuation than an unlined elbow of the same size. For alternative lining materials, consult individual manufacturers.

It is difficult to write specifications for sound attenuation because it changes with every duct dimension and configuration. Thus, insulation materials are generally selected for attenuation based on sound absorption ratings. Sound absorption tests are run per ASTM Standard C423 in large reverberation rooms with random sound incidence. The test specimens are laid on the chamber floor per ASTM Standard E795, Type A mounting. This mode of sound exposure is quite different from the exposure of internal linings installed in an air duct. Therefore, sound absorption ratings for materials can only be used for general comparisons of effectiveness when used in air ducts of varying dimensions (Kuntz and Hoover 1987).

Breakout noise comes from vibration of the duct wall caused by air pressure fluctuations in the duct. Absorptive insulation can be used in combination with mass-loaded jacketings or mastics on the duct exterior to reduce breakout noise. This technique is only minimally effective on rectangular ducts, which require the insulation and mass composite to be physically separated from the duct wall to be effective. For round ducts, as with pipes, absorptive insulation and mass composite can be effective, even when directly applied to the duct surface.

Other Design Considerations

Abuse Resistance

Depending on the intended location, insulation may be subjected to mechanical abuse during its service life. The source of this abuse may be personnel, equipment, machinery, etc. In some areas, personnel must gain access for maintenance. Foot traffic then becomes a design consideration. Rigid jacketing provides some protection against damage from mechanical abuse. The compressive resistance of the insulation material also should be considered when designing for mechanical protection.

Corrosion under Insulation

Corrosion of metal pipe, vessels, and equipment under insulation, though not typically caused by the insulation, is still a significant issue that must be considered during the design of any mechanical insulation system. The propensity for corrosion depends on many factors, including the ambient environment and operating temperature of the metal.

CUI is caused by the ingress of water into the insulation, which traps the water in contact with the metal surface. The water can be rainwater, leakage, deluge system water, wash water, or it can come from sweating from temperature cycling or low-temperature operation such as refrigeration units. Water is the primary ingredient for CUI. Without water, corrosion will not occur.

CUI on carbon steel and alloy steel surfaces unfortunately is a common problem across all industries and often remains undetected until the insulation is removed or a leak or other event, some of which can be extremely hazardous, occurs. Some estimates put the global cost of CUI over $2.5 trillion dollars, and that 40–60% of all monies spent on pipe and equipment maintenance in the oil and gas industry is a result of CUI.

The problem occurs in carbon steels and 300-series stainless steels. On the carbon steels, it manifests as generalized or localized wall loss. With the stainless pipes, it is often seen as pitting and corrosion-induced stress corrosion cracking. Though failure can occur in a broad band of temperatures, corrosion always is a significant concern. Association for Materials Protection and Performance (AMPP), formerly known as NACE International, (www.ampp.org) has concluded that CUI is more prevalent in the service temperature range of 25°F (-4°C) to 350°F (175°C) for carbon steel and 120°F (50°C) to 350°F (175°C) for austenitic or duplex stainless steel.

CUI is most prevalent in outdoor environments, such as refineries and chemical plants. Corrosion can be very costly because of forced downtime of processes and can be a health and safety hazard as well. Although insulation itself may not necessarily be the cause of corrosion, it can be a passive component because it is in direct contact with the pipe or equipment surface.

It is not likely that corrosion is a major concern for most insulated surfaces located indoors, unless an area is subject to frequent wash down—such as in the food-processing industry—or has been exposed to water from some source, such as sprinkler systems, spills, etc.

Water from condensation on cold surfaces can be present on both indoor and outdoor insulation systems if there is damage to the vapor retarder. Hot processes can also be subject to condensation during periods of system shutdown.

The following factors may lead to CUI.

- Water must be present. Water ingress may occur at some point on insulated outdoor surfaces. The entry point for water may be through a number of areas including: 1) breaks in weatherproofing materials, such as mastic, caulk, or adhesives; 2) improperly sealed penetrations and termination points; and 3) areas damaged as a result of ladders or foot traffic.

- A general lack of timely and consistent inspection and maintenance increases the potential for corrosion.

- Temperature affects the rate of corrosion. In general, higher temperatures increase the corrosion rate.

- Contaminants in the environment can accelerate corrosion. For instance, chlorides or sulfates could reside on the insulation's exterior jacket and then be washed into the insulation system by rain or wash down. Other sources of chloride ions include rainwater, ocean mist, and cooling-tower spray, each of which can provide a major and virtually inexhaustible supply of ions. Even if the level of chloride ions in the water is low, significant amounts of ions can accumulate at the pipe surface by a continuing cycle of water penetrations and evaporation. Chloride ions only contribute to stress corrosion cracking of stainless steel when water (liquid or vapor) and the ions are present at the surface of a pipe at temperatures above ambient, usually when the surface is above about 140°F and below about 300°F. Exposure of the insulation system to water from some outside source is inevitable, so the key to eliminating stress corrosion cracking lies in preventing moisture and ions, even in small amounts, from reaching the metal surface.

- Insulation can contain leachable corrosive agents.

- Austenitic stainless steels are particularly susceptible to attack from chlorides and are generally classified as "188s": austenitic alloys containing approximately 18% chromium, 8% nickel, and the balance iron. Besides the basic alloy UNS S30400, these stainless alloys include molybdenum (UNS S31600 and S31700), carbon-stabilized (UNS S321000 and S347000), and low-carbon grades (UNS S30403 and S31603) (NACE 2004).

For outdoor applications, no insulation material alone can prevent penetration of moisture and ions to the metal surface, so additional lines of defense—such as a properly designed, installed, and maintained protective jacket—are necessary. If process temperatures are lower than ambient (even for short periods of time, such as during shutdowns), a vapor retarder is also required.

Even with a protective covering or jacket and vapor retarder, it is likely that some moisture and ions will eventually enter the system because of abuse, wear, age, or improper design, installation, or maintenance. No installation is ideal in any real-world setting. Because most people only consider the chlorides arising from the insulation material, the crucial issue of water and ions infiltrating the insulation system from the environment and yielding metal corrosion remains unaddressed. Thus, coating the pipe is the second and most important line of defense, and it is necessary if pipe temperature is in the 25°F to 300°F range for significant periods of time. To minimize the potential for corrosion, metal pipe should be coated. This approach offers additional protection against corrosion because coating protects against ions arising from the insulation and, more importantly, from ions that enter the system from the environment.

To minimize corrosion:

- Design, install, and maintain insulation systems to minimize ponding water or penetration of water into the system. Flat sections should be designed with a pitch to shed water. Top sections should overlap the sides to provide a watershed effect, preventing water penetration in the seam. Design should always minimize penetrations; necessary protrusions (e.g., supports, valves, and flanges) should be designed to shed, rather than capture, water. Water from external sources can enter at any discontinuity in the insulation system.

- Insulation should be appropriate for its intended application and service temperature. AMPP's NACE (www.ampp.org) SP0198 states, "CUI of carbon steel is possible under all types of insulation. The insulation type may only be a contributing factor. The insulation characteristics with the most influence on CUI are (1) water-leachable salt content in insulation that may contribute to corrosion, such as chloride, sulfate, and acidic materials in fire retardants; (2) water retention, permeability, and wet ability of the insulation; and (3) foams containing residual compounds that react with water to form hydrochloric or other acids. Because CUI is a product of wet metal exposure duration, the insulation system that holds the least amount of water and dries most quickly should result in the least amount of corrosion damage to equipment."

- Ancillary materials used for weatherproofing (e.g., sealants, caulks, weather stripping, adhesives, and mastics) should be appropriate for the application and applied following the manufacturer's recommendations.

- Maintenance should monitor for and immediately repair compromises in the protective jacketing system. Because water may infiltrate the insulation system, inspection ports should be used to facilitate inspection without requiring insulation removal.

- Because the potential for some water ingress is high, a protective pipe coating should be considered as a part of the design. In Europe, essentially all piping is coated for corrosion protection. This is not necessarily the case in the United States, but it should be considered as part of good design practice. The type of coating depends on temperature (see AMPP's NACE SP0198 for coating guidelines).

When using austenitic stainless steel, all insulation products and accessories should meet the requirements of ASTM Standard C795. Likewise, any ancillary weatherproofing materials should have low chloride content.

CUI has generated a lot of discussion about the drain plugs or drain/weep holes being installed in an insulation system. A drain hole or plug is defined as a hole that is designed to drain off accumulated water. In other words, if you accept that moisture from some source is going to get into the insulation system, then design an exit portal so that moisture does not remain at the substrate level over any extended period of time. The theory is simple: moisture in, moisture out.

Indoor Air Quality

When mechanical insulation products are exposed to occupied spaces, or exposed to HVAC duct systems that serve occupied spaces, indoor air quality becomes a design consideration. While most mechanical insulation systems are inherently stable, and are typically installed with a protective finish or jacketing, there are situations where the emission of volatile organic compounds (VOCs) or respirable particles could be a concern. In response to these concerns, a number of organizations have developed standards to define products with low chemical and particle emissions for use indoors. The standards establish certification procedures including test methods, allowable emissions levels, product sample collection and handling, and testing type and frequency. One sources of information is the Greenguard Environmental Institute (www.greenguard.org). To obtain VOC and particle information for a specific product, the respective manufacturer should be contacted.

Greenguard defines VOCs as follows: “Volatile organic compounds (VOCs) are chemicals used to manufacture and prepare many building materials, interior furnishings, textiles, office equipment, cleaners, personal care supplies, and pesticides. ‘Volatile’ is a term meaning that these chemicals evaporate, or get into the air easily at room temperature.” That is why they are an indoor air concern. Studies by the U.S. Environmental Protection Agency (EPA) and other researchers have found that VOCs are common in the indoor environment and that their levels may be tens to thousands of times higher indoors than found in the outdoor air. There may be anywhere from 50 up to hundreds of individual VOCs in an indoor air sample. The majority of these VOCs are emitted from indoor materials and processes. Some may produce odors at very low levels that are considered objectionable. Many VOCs are irritants and can result in headaches and eye, nose, and throat irritation, as well as dizziness. At high concentrations, some VOCs are toxic.

“Organic” is another chemical term, meaning that these types of chemicals contain carbon. Since carbon burns, many of these chemicals, including organic solvents, are flammable. Common VOCs in homes, offices, and schools include formaldehyde, decane, butoxyethanol, isopentane, limonene, styrene, xylenes, perchloroethylene, methylene chloride, toluene, and vinyl chloride.

The U.S. EPA website (www.epa.gov/iaq/voc.html) contains some background information on the sources and control strategies for VOCs in buildings.

Maintainability

Insulation systems, like all mechanical systems, require periodic inspection and maintenance. This fact should not be overlooked during the design phase of a project. Designing for maintainability should consider the following:

- Proper design and sealing of weather barriers,

- Allowance for expansion and contraction of the system,

- Access for inspection,

- Access for repair and/or replacement of the equipment being insulated, and

- Requirements for wash down.

Leaks are most likely to occur at valves, fittings, and flanges. Removable fitting covers may be specified at predictable maintenance areas. A systematic inspection and replacement program can help prevent large-scale insulation destruction due to leakage.

Regulatory Considerations

The insulation designer should be aware of any special regulatory considerations that must be addressed. These are generally dictated by the application. Examples include U.S. Department of Agriculture (USDA) or Food and Drug Administration (FDA) requirements. Leak detection is a regulatory requirement for some chemical processes. Nuclear power plants will have specific requirements for insulation materials used within containment facilities, in addition to requirements for insulation used on austenitic stainless steel. Insulation used on vessels may be subject to requirements from the U.S. Coast Guard (USCG), International Marine Organization (IMO), U.S. Navy (NAVSEA) or other sources.

Service and Location

The service and location of the items to be insulated ("what and where?") are obviously important design considerations.

“Service” refers to the function of the piping or equipment being insulated. Some typical services include hot water, chilled water, dual-temperature water, steam, heat-transfer fluids, oils, refrigerants, brines, liquefied natural gas (LNG), supply air, return air, etc. The type of service will largely determine the operating temperature of the insulation system. It may also dictate other important elements of the design. An example would be fire safety concerns associated with a possible leak of flammable heat-transfer fluids.

The location determines the ambient conditions that should be used in calculating the insulation thickness. Location also plays an important role in the choice of accessories, such as the jacket type and the method of securement. In high-wind areas, band spacing should be reduced to keep the jacket in place. In corrosive areas, such as those close to the seacoast or to corrosive chemical fumes, it may be necessary to select a jacket material that is resistant to the specific corrosive condition. Equipment located inside a building is not exposed to weather extremes or UV light, so less durable jacket materials—or, in some cases, no jacket material—can be suitable.

Service Life

The service life of the mechanical insulation system is a design consideration and must be estimated when doing life-cycle cost analysis. Insulation is a passive material and will generally perform its function indefinitely if designed properly, installed correctly, and kept timely maintained. However, in many applications, the insulation can be exposed to disturbing agents. Physical damage is possible in high-traffic areas, and abuse protection should be considered to extend the service life of the system. Mechanical vibration can also be a source for insulation degradation in some applications. Protection from the weather (rain, wind, snow, ice, and UV exposure) is important for outdoor systems. Below-ambient systems are subject to damage from water vapor intrusion, which may lead to the buildup of liquid water or ice. These disturbing forces should be considered during the design phase and addressed accordingly.

References

1 The term mechanical insulation is used to describe insulation systems utilized for mechanical piping and equipment, HVAC applications, and refrigeration piping and equipment applications.

2 U.S. Energy Information Administration

3 Economic thickness should not be confused with the "critical radius" concept discussed in some heat transfer textbooks. The critical radius is that thickness that maximizes the heat transfer for a radial system. Most insulation systems are intended to minimize heat transfer and involve thicknesses well beyond the critical radius.