Understanding ASTM Test Methods Evaluating Thermal Insulations and Corrosion of Metals

Corrosion under insulation (CUI) is one of the most significant issues facing industrial facility owners, engineers, and maintenance personnel who work with above-ambient process piping and equipment. Unfortunately, CUI can be very difficult to detect, often only being discovered after it has caused significant damage. There are several non-destructive methods for detecting in-situ metal loss without removing the insulation, such as infrared scanning. However, such methods involve costly equipment and can evaluate only a small area at a time. The most predictable and cost-effective method to manage CUI is a systematic inspection program. In this program, specially-trained workers carefully cut cores out of the insulation system, perform a visual inspection of the base metal, and then install properly sealed inspection plugs. Other methods involve removing a small percentage of the insulation in CUI-prone areas, inspecting the base metal, and then re-covering the exposed pipe with new insulation and cladding. Many facilities departments tasked with creating and implementing an effective CUI-inspection program report very limited budgets and available personnel to carry out this critically important task, which must continue in perpetuity.

Fortunately, to facilitate the creation of safe industrial environments, an organization called ASTM International developed test methods and material standards to ensure insulation products meet performance and material standards. ASTM International plays an important role in providing the technical data and physical properties for a broad range of materials, including insulation. It has a long reputation as a credible, non-biased source for test methods and material standards, and as such can be an essential resource for specifiers who are looking for insulations with excellent CUI performance.

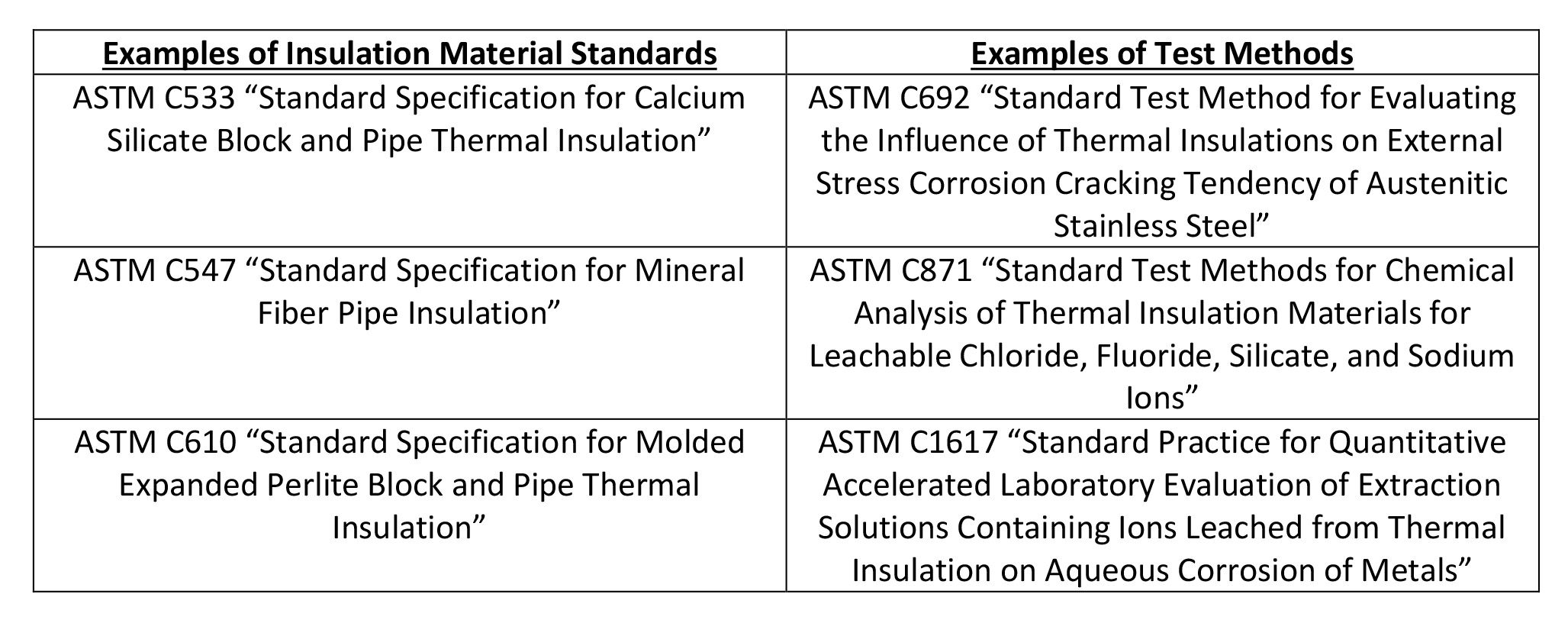

It is important to note that ASTM test methods and ASTM material standards are not the same thing. There are several different test methods that help designers evaluate corrosion rates. These test methods then set the minimum standards that insulation products must pass in order to be considered safe for specific applications. The chart above shows a few examples of ASTM standards compared to ASTM test methods that are commonly seen in the insulation industry.

Test methods are exactly that—they lay out a plan to test, evaluate, and report specific physical properties. In contrast, material standards are the specified results that must be achieved via the applicable test methods in order to claim that a particular insulation material is compliant with the ASTM standard. Generic material standards are often specified by engineers to ensure competition and not show favoritism to one manufacturer or another. As long as a given product meets the insulation-specific minimum requirements, it can be considered an eligible material to bid on the project.

Caution is advised here as some specifications are not generic, but instead insulation specific. This means that it is possible for 2 different insulation materials to meet their own minimum requirements, but one may suit a particular application better than the other as to one or more attributes.

The following is a list of brief explanations of 4 commonly specified corrosion ASTM material standards and test methods.

- The ASTM C795 “Standard Specification for Thermal Insulation for Use in Contact with Austenitic Stainless Steel” was developed in 1977 and requires the insulation to pass both the C692 and C871 test methods to be deemed acceptable for use on stainless-steel piping and vessels.

- The ASTM C692 “Standard Test Method for Evaluating the Influence of Thermal Insulations on External Stress Corrosion Cracking Tendency of Austenitic Stainless Steel” was developed in 1971 and is a pass/fail test based on a visual determination of the cracking of austenitic stainless-steel coupons. Unlike ferrous (iron-based) steel that rusts, stainless steel will fail through a process known as external stress corrosion cracking (ESCC).

- Involves dripping de-ionized (DI) water on a piece of insulation placed on top of a heated/stressed stainless steel coupon for 28 days. If the steel shows any cracking under a microscope, the insulation will fail.

- The ASTM C871 “Standard Test Methods for Chemical Analysis of Thermal Insulation Materials for Leachable Chloride, Fluoride, Silicate, and Sodium Ions” was developed in 1977 and creates a threshold curve for allowable amounts of various corrosive ions contained in the insulations.

- Helps manufacturers ensure their chemical formulations help reduce the potential for CUI being caused by the insulation itself.

- The ASTM C1617 “Standard Practice for Quantitative Accelerated Laboratory Evaluation of Extraction Solutions Containing Ions Leached from Thermal Insulation on Aqueous Corrosion of Metals” test was developed in 2005 for mild steel. It involves grinding up insulation, boiling it into an extraction solution, and then dripping the solutions onto coupons heated to 230°F (+10°F) so each drop is quickly vaporized. The coupons are weighed before the test, and are weighed again after the test once the coupon has been cleaned to remove corrosion products formed during the test. The mass loss is mathematically extrapolated and expressed as a Mass Loss Corrosion Rate (MLCR) in mils per year. The rates are compared to various control solutions including DI water and 1-ppm and 5-ppm chloride solutions.

- This test creates the “perfect storm” to induce visual and measureable corrosion through hundreds of wet/dry cycles over 96 hours. While the older corrosion test strictly relies on visual results, C1617 provides objective, quantifiable data of the actual metal loss due to corrosion caused by the chemical formulation of the various insulations.

Most ASTM material standards for industrial insulation contain one or more of these test methods regarding corrosion. Whether or not a given insulation material standard contains a particular test method is a function of how old the latest version is, how active the ASTM committee members are, or the difficulty in gaining consensus among the members to add or modify existing standards. One thing many fail to realize is that ASTM is a consensus group, meaning that edits, additions, or deletions to a document must receive approval from every member that votes on the issue. A single “no” vote from an active member of the committee requires an involved review process to override, slowing or preventing any change to the standard. This protects the broader community and prevents individuals or groups from passing self-serving standards that do not benefit the industry as a whole. This also helps engineers know that every word of the standard is deliberate and agreed upon by all of the members of the committee.

One such example of a “newer” ASTM test method regarding corrosion is ASTM C1617 (cited above). This test method has been adopted into several, but not all, insulation material standards. As these standards frequently take extensive amounts of time to gain consensus within each committee, the absence of a particular test method should not call into question the corrosion performance of any insulation standards that do not yet reference the test.

What is perhaps more important to note is that a “pass” for ASTM C1617 on different material data sheets may not necessarily mean the same level of performance. One must take the time to read the actual material standard to see what the passing criteria are because, as noted above, they can vary from one material standard to another. For instance, the ASTM C533 standard (cited above) section 12.1.12 states, “The Mass Loss Corrosion Rate . . . shall be equal to or less than . . . DI water.”Simply stated, that means that the material must be tested via the C1617 test method to determine whether or not it causes less corrosion than the DI water. However, the C547 material standard references the same C1617 test method, but the corrosion loss requirement reads, “Shall not exceed that of the 5-ppm chloride solution.” Clearly, a higher chloride control solution will cause more corrosion than DI water, so one must understand exactly where the bar is set in order to compare the various chemical formulations that either promote or inhibit aqueous corrosion of metals.

The insulation industry must lead the way in helping designers and facility owners directly face the costly battle against CUI. Industry members at all levels should educate themselves on the science behind corrosion and be able to logically explain how insulation plays a role. This would be a great way to increase credibility of the industry, help lower energy costs, and reduce CUI potential within affected systems.

This article was published in the October 2015 issue of Insulation Outlook magazine. Copyright © 2015 National Insulation Association. All rights reserved. The contents of this website and Insulation Outlook magazine may not be reproduced in any means, in whole or in part, without the prior written permission of the publisher and NIA. Any unauthorized duplication is strictly prohibited and would violate NIA’s copyright and may violate other copyright agreements that NIA has with authors and partners. Contact publisher@insulation.org to reprint or reproduce this content.

Disclaimer: Unless specifically noted at the beginning of the article, the content, calculations, and opinions expressed by the author(s) of any article in Insulation Outlook are those of the author(s) and do not necessarily reflect the views of NIA. The appearance of an article, advertisement, and/or product or service information in Insulation Outlook does not constitute an endorsement of such products or services by NIA. Every effort will be made to avoid the use or mention of specific product brand names in featured magazine articles.