A Different Perspective Editorial: Lessons from Experience for the Power Generation Industry

Power plant owners and operators have experienced degradation of their boiler insulation. Damage can be caused by storms impacting exterior boilers, tube leak repairs, other modifications, or the pull of gravity over an extended time period. Degraded insulation creates a boiler performance problem in addition to hazards for personnel and nearby equipment.

Restoring lost insulation can be a difficult and expensive proposition due to limited access and large surface areas involved. The typical steam-generating boiler efficiency penalty caused by heat lost to the atmosphere is in the range of 0.25% to 0.4% when the insulation is in perfect condition. On the plus side, a proper insulation design and installation can save as much as 5% to 7% in fuel cost (oil, gas, coal, or refuse), paying for approximately 5% of the initial boiler construction cost.

The power generation industry needs cost-effective and thermally efficient insulation systems on its steam-generating boilers to maintain efficiency and ensure personnel and equipment safety. This key component can fail due to improper installation or design of the insulation (and lagging) systems. Experienced and qualified contractors—and, in some cases, plant maintenance personnel—are key to correct installation. Insulation systems fail because the power industries—including designers—often fail to understand how far the industry has regressed. For many reasons, the power industry has gone through major reorganization, mergers, and plant shutdowns. This, in conjunction with an aging workforce, has led to a change in how the industry looks at insulation of its steam-generating boilers. Fewer than 20 years ago, most power boiler companies and original equipment manufacturers (OEMs) understood the importance of insulation for energy efficiency. These same companies also had training and continuing education programs to help keep their boilers operating efficiently while keeping their installation costs reasonable. Unfortunately, much of the expertise and knowledge in today’s boiler industry has been lost or forgotten.

That loss of knowledge has, in turn, led to the end of keeping historical records for the insulation systems used on steam-generating boilers. Once keeping historical information stopped, the continuing education programs also began to dwindle. The industry has suffered as a result because reviewing historical data helps improve boiler design; correct design flaws; document labor variances; improve labor productivity; and establish better costs, budgets, and bids.

Loss of Historical Data

Without historical data, it inevitably costs more to repair or replace existing insulation systems and equipment. With the technology and tools available today, it is easier than ever to record and track data, but this must be an ongoing process, and the data recorded needs to be kept for historic records to give companies an overall view of their system’s performance and successes. Here are 3 examples of the effects of a lack of historical data.

Example 1. Many boiler manufacturers design (and supply) their flues, ducts, and emission control equipment systems without taking into consideration the cost or effect their stiffener designs will have on the insulation and lagging that will be required later in the project. Historical data would support and confirm that using large stiffeners (greater than 7 inches high) is detrimental to the longevity and integrity of the insulation and lagging systems being designed and installed today.

Example 2. Many OEMs and power generation companies have changed their standards to mandate double-layer applications on their boiler walls. The thinking is that double-layer application is better than single layer because it eliminates gaps between the individual insulation pieces and reduces the chances for hot spots on the outer lagging or

casing surface. However, there is no documentation to support that this is universally true. Historical data could confirm or disprove whether using double-layer instead of single-layer insulation provides a better insulation system. Going to double layer does not ensure the elimination of gaps or prevent improper insulation applications, but proper installation does.

Figure 1 through Figure 3 illustrate some examples of how installing a double-layer system does not prevent costly mistakes. Each of these photos represents violation of most OEM installation specification requirements.

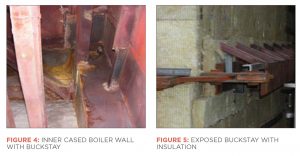

Example 3. Some companies increase the insulation on existing boiler walls or soon-to-be-built boilers from the original design of 4” thick to 5” thick, based on the theory that more insulation is better for energy savings. While insulation provides energy savings, the buckstay design should not be neglected when making this change. Historical data would show that increasing the boiler wall insulation without also changing the distance of the buckstays to the tube wall can create other problems (see Figure 4 and Figure 5) that may outweigh the desired savings.

Lack of Continuing Education and the Need for a Boiler Standard

The lack of a continuing education programs for the power industry is also costing the industry money. A typical power plant may have 2 or 3 different types of boilers, with different tube wall designs. Such a scenario requires personnel with specialized understanding of all the different types of boilers, their unique operation requirements, the large multidirectional expansion that can occur, and the potential need to install the materials while the boiler is in operation. Adding to this is the impact that changing fuels, adding gas turbines, or going to a co-generating system has on the power and insulation industries. We must begin to take note of these changes, especially when converting to alternative fuels in existing boilers. We also must anticipate and adjust to new outage requirements when adding gas turbines to replace existing coal- or oil-fired units. And we must change how we view the importance of both insulation and refractory when adding a co-generation system.

Understandably, working in the power industry has changed over time. No longer do the power plants and OEMs have the expertise or personnel to monitor proper installation of their insulation systems; and most of the workforce used to install insulation has limited or no experience working at power plants. Each boiler may have its own set of standards and applications, depending upon who manufactured the boiler. There can be confusion as to what insulation system is to be used and how to install the system. Consider the following examples:

- Example 1. 1 boiler may require insulation behind the buckstays, whereas another may require a poured insulation.

- Example 2. 1 boiler may require the penthouse enclosure to be internally insulated, while the boiler next to it has an externally insulated and lagged penthouse enclosure.

- Example 3. 1 boiler may be top supported, while the boiler next to it is a bottom-supported unit. The expansion is different and must be accounted for.

- Example 4. 1 boiler may require a 1-rib overlap on the outer lagging, whereas another does not.

- Example 5. 1 boiler may have insulation attachments on 12” centers, compared to another boiler requiring a different spacing (e.g., 18” x 21”).

- Example 6. 1 boiler may require buckstay covers even as another right next to it does not.

Not listed above but equally important are the different ways to insulate pipe, valves, and fittings. When a power plant changes from coal fired to gas turbines it will no longer be necessary to inspect the air heater baskets as often or remove and replace large areas of boiler wall insulation. In lieu of this typical type of work during outages, there will be more emphasis on efficiency and heat loss. Piping standards, like boiler wall insulation standards, differ from 1 boiler manufacture to another and will need to be consolidated

or revised.

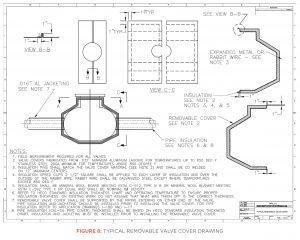

Here is an example: When doing frequent inspections of large steam valves, removable insulated valve covers will be needed. In years past, the valves may only have been inspected every 2 years, and they were wrapped with an insulated blanket and covered with jacketing. Now, the frequency will be once or twice a year. Labor will need to know how to fabricate a removable valve cover. (Please see Figures 6, 7, and 8.)

The examples described are not all inclusive, which is why many in the industry are calling for unification or the development of agreed-upon insulation application standards that may be applied to all membrane or inner-cased boilers, and on gas turbines and co-generation systems. The need for such standards is demonstrated by all of the examples and issues described in this article; and it would address the fact that working at a power plant requires a special understanding of the different types of boilers; their unique operation requirements; and the large, multidirectional expansion that can occur.

Power and Insulation Industries Expanding

The power and insulation industries are going through a growth and change not seen since the late seventies and early eighties. Power companies will be spending billions of dollars on new power plants, retrofitting to accommodate new fuels, adding a co-generation system, or moth-balling their existing coal-fired boilers and replacing them with gas turbines. The power industry must educate all its workers on the importance of maintaining good historical data, and it must keep up with training for working at a steam-generating plant. To improve the power industry, we need to develop and maintain a well-educated workforce. This should apply not just at the power plants but also include boiler inspectors dealing with insulation applications and OEM companies and suppliers. To accomplish this, everyone—including labor associations—must work together to improve the power generation industry.

With the increase in today’s new boiler construction, including heat recovery steam generators, now is the time to increase the level of understanding of insulation and of the value of keeping historical data, increase the availability of continuing education programs, and agree upon an insulation application standard that makes sense for saving energy and is easy for installers to understand and follow.

Conclusion

Lower fuel costs coincide with lower equipment and maintenance costs. Energy savings can be achieved by properly designing and installing insulation (and lagging), and it begins with a better educated workforce and recording and maintaining historical data both at the plant level and at the OEMs. Implementing these recommendations will help establish industry standards for proper insulation applications and provide the industry with the information needed to improve boiler and plant reliability.

Copyright statement

This article was published in the June 2020 issue of Insulation Outlook magazine. Copyright © 2020 National Insulation Association. All rights reserved. The contents of this website and Insulation Outlook magazine may not be reproduced in any means, in whole or in part, without the prior written permission of the publisher and NIA. Any unauthorized duplication is strictly prohibited and would violate NIA’s copyright and may violate other copyright agreements that NIA has with authors and partners. Contact publisher@insulation.org to reprint or reproduce this content.