A Different Perspective: Boiler Specifications in the Power Industry

You might think reading a brick, refractory, insulation, and lagging (bril) specification would be easy, but not so in the power industry. Many errors in design and application could be avoided if all the stakeholders involved had a better understanding of how to read a specification. If you want a long-lasting “bril” installation, it begins with the specification.

In the power industry, there are three different kinds of specifications for these critically important components of a steam-generating boiler. Each specification occurs at different times of the project, each with a different purpose or intent. From engineering and design to material supply and installation, these specifications provide the background and standards used in the power industry.

Regardless of what type of bril specification you are reading, it becomes clear that many items or topics are not fully explained; and in many cases, it is assumed that you already know what is referred to in the specification. Here are some typical examples of knowledge that is often assumed (rather than made clear in the specification):

- That “bril” can mean the same as “boiler setting,”

- The difference between curing and dry-out (also known as bake-out),

- How still air affects the calibration of insulation thickness requirements,

- What a parting agent is used for, and

- What a coal tar-based material used as a parting agent is.

These are just a few examples of what you may encounter when reading a specification. In order to understand how to read a “boiler setting” specification, you must understand the process.

Here is an example of how the process works: A power company wants a new boiler at one of their plant locations. The power company, in most cases, turns to an engineering company to help them develop a boiler specification for a request for quotation (RFQ) from original equipment manufacturer (OEM) boiler companies.

Most often, the RFQs to the OEMs do not include the construction of the boiler or the supply of the “boiler setting” materials. Included in the engineering specification is information on the minimum design requirements for the boiler setting that will support the designed boiler performance. The OEMs must review the engineering specification in fine detail and compare the information to their own company standards. From that review, they will base their bid and boiler design. The power company will eventually award the boiler to one of the OEM companies, and then the real boiler setting specification begins. The OEM will develop the boiler setting specification that will comply with what was sold. This is the specification most often read by construction companies, bril contractors, erectors and supervisors at the job site, engineers at the home offices, and purchasing and procurement departments.

Reading and understanding boiler setting specifications requires:

- An understanding of your own company standards,

- Knowing how changing or deviating from your own company standards will affect your boiler design and boiler setting installation and material costs,

- Knowing terms and definitions used, and

- Knowing what items in the specification are commercial items that may or may not be addressed with dollars but must be considered and complied with.

The Process

All the different specifications mean that a lot of background information and experience is required to be able to grasp the full intent of the specifications. In order to better understand the differences, we shall use as an example OEM-A “bril” standards and compare them to the engineering specification to see the effect it may have on their boiler and “bril” design. Note that most engineering specifications do not include refractory. Their intent or focus is generally on things that affect boiler thermal performance (even though some can argue that refractory is equally important as insulation). Engineering specifications often defer specifying refractory requirements to the OEMs.

Scenario One:

A power company hires an engineering company to help them send out an RFQ to boiler manufacturing OEMs that includes the design requirements of insulation and lagging.

The following are three examples of the different engineering specifications and how they may affect the boiler OEM insulation and lagging “setting” requirements.

Engineering Company ENG-1

- Requires insulation thickness to be designed using still air.

OEM-A’s company standard is 50 feet per minute wind velocity, which would require the company to either accept or take exception to the requirement and quote their company-standard insulation thickness based on the following: Using still air increases the insulation thickness requirements on their boiler from single layer to double layer (4” thick to 4½” thick).

Note: The boiler’s buckstays would have to move farther away from the boiler wall tubes to make room for the thicker insulation that goes behind the buckstay. Still air or an external wind velocity of zero is low risk. At a power plant, it does not actually exist, and is used by engineering companies as a means of being conservative in their design requirements. Still air is theoretical and not actual. - Requires that all top surface areas(i.e., penthouse roof, flues, and ducts)be designed as a walking surface. This is an additional cost, as OEM-Acompany standards do not require top surfaces to be designed as a walking surface. They would clarify that their company will use a calcium silicate block meeting ASTM C533 with no free silica in lieu of a mineral wool board meeting ASTM C612 Type IVB to achieve a walking top surface.

- States “…bolts, if used, shall be not over 2½” centers…”OEM-A would clarify that their company does not use bolts to hold or retain any of their materials, and they use stainless-steel screws on 24” x 36” centers.

Engineering Company ENG-2

- Requires a 30-year warranty on insulation material. This is a commercial item and would be addressed by their legal or commercial group, or OEM-A would take exception knowing they have the following clause already in their company standards: All insulating material shall be of such quality to be suitable for the purpose intended and be capable of giving effective and reliable service under normal operating conditions.

- Requires surfaces 850oF and under to beinsulated with minimum 8#/cf density mineral wool board (all insulation supplied must be not less than 8#/cf). OEM-A company standards specify a nominal 8#/cf density mineral wool board (average density is around 8#/cf) on all surfaces 850oF and below. Requiring a minimum density material increases material cost but does not change the thermal properties of the insulation. A nominal density material is cheaper to manufacture and easier to procure (shorter lead times).

- Requires using road mesh as an inner insulation support over stiffeners. OEM-A would have to clarify this item to state that they intend to use 22-gauge

corrugated inner lagging in lieu of road mesh based on the following reason: Using 4” x 4” road mesh would not prevent insulation from degrading after binder burnout and is not recommended to prevent the loss of insulation material over time due to normal vibrations during operation.

Engineering Company ENG-3

- Requires insulation to be designed to limit cold face temperature to 130oF maximum with an 80oF ambient air temperature. No clarification would be needed as this is the same as in OEM-A’s company standards.

- Requires all insulation to be securely wired and laced in place. Clarification would be needed because all mineral wool boards and blankets will be held with insulation pins and clips, not wired in place.

- Requires that all flat insulated areas (boiler walls) that require 4” insulation thickness

shall be double-layer construction. This is a major cost item for labor and material (it requires more insulation clip attachments). OEM-A company standards on boiler walls requiring 4” insulation thickness will be in single-layer construction wherever possible. - Requires outer aluminum rib lagging to be .040” thick, and .050” for flat aluminum lagging. This also adds cost, as OEM-A’s standards use .032” rib aluminum and .040” thick for flat aluminum.

Scenario Two:

A power company has awarded the boiler contract to an OEM. The OEM begins to develop a “boiler setting” specification showing the minimum requirements for its steam-generating unit. This specification will be used for the procurement and installation of the required boiler setting material, but it is not part of their scope of supply at this time.

This boiler setting specification is developed by the boiler supplier, so you must be familiar with the differences of “boiler setting” specifications that come from different OEM companies. Fortunately, they all have similar items covering standard “commercial” items, and all must convey the purpose or “intent” of their specification. For example:

This refractory specification is intended to cover instructions and guidelines that are to be followed for the supply and installation of refractory for the steam-generating unit. It is realized that a cost savings may be inherent in alternate designs to those being presented in these specifications. However, it will not be practical to cover every conceivable detail or alternate method that may arise. As is the case in all phases of construction, good common sense and judgment must be exercised in conjunction with this standard specification.

This paragraph gives us the following information:

- The specification is for refractory only.

- It is to be used for both the supply and installation of the refractory.

- The specification does not cover every single detail.

- It assumes the reader understands construction and alternate methods of construction.

Next, most specifications have similar commercial items that should be identified as such, and they are equally important as the rest of the specification. Examples of commercial items:

- The Refractory Contractor shall furnish all material and labor necessary to fabricate, install, and remove any forms that may be necessary to properly apply or install the materials. This item assumes that the reader knows the following: What the forms are to be made from, that the forms cannot be removed until the refractory has been cured for 24 hours, and that the forms should be painted or coated with a parting agent or lined with plastic to prevent the refractory from sticking to the form when removed.

- Potable water, tap water (non-potable), and electricity for construction purposes will be made available to the Refractory Contractor by the Company. The Refractory Contractor is to supply extension cords, lamps, water hoses, and any other equipment needed to complete their work. This item assumes that the reader knows what potable water (drinking water) is and is not (e.g., river water).

- Materials furnished by the Refractory Contractor shall be unloaded, stored, and weather protected by the Refractory Contractor until applied. This item assumes that the reader knows that ultimate responsibility for unloading, storage, and weather protection is theirs; and that it is their responsibility to ensure it is properly done. If adequate storage is not available at the site, it will be your responsibility to locate or provide storage.

- No materials which are used or furnished by the Refractory Contractor in connection with this scope of work including but not limited to, all insulation materials, cements, gaskets, packing, roping, etc. shall contain any amount of asbestos. All materials being furnished under this contract must be asbestos free and the Company shall reject any and all asbestos-containing materials. This item assumes the following: The reader knows that asbestos has been banned from use since the early 1970s. The reader knows what asbestos is and what products can be substituted for its use.

- No coal tar-based products can be used as parting agents. This item assumes that the reader knows the following: What “coal tar-based” products (e.g., bitumastic super service black paint) are, and what they were used for in the past (parting agent). That the ingredients of these coal tar emulsions are classified as carcinogens.

- The Refractory Contractor is responsible for curing installed refractory material. This item assumes that the reader knows the following: All cement-bonded refractory materials must be cured for a minimum of 24 hours by the installing refractory contractor. The term “curing” means keeping the installed refractory material wet, or the surrounding atmosphere humid, to create the most favorable conditions for the completion of the chemical reactions of the cement.

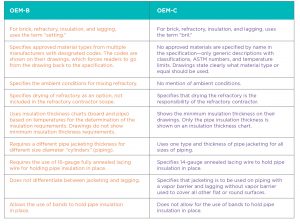

After the commercial items have been addressed, it is time to look at how different OEM “boiler setting” specifications differ. For this comparison, we shall review information and standards from two actual OEMs—called OEM-B and OEM-C for the purposes of this exercise—to see how their “boiler setting” specifications differ.

There are many more differences beyond those described here. It is apparent that specifications are not generic and require very specific knowledge. Errors could be avoided just by more thorough reviews of specification requirements. As an industry, we need more training, and possibly a unification of standards for “boiler setting” materials and applications. Ultimately, the power industry needs well-written specifications as the first step in getting a properly designed and longer lasting “boiler setting” installation.