2024 Commercial Energy Code Update

Over the last year, the commercial energy code landscape has seen several new state- and local-level adoptions, in addition to the publishing of a brand new American Society of Heating and Air-Conditioning Engineers (ASHRAE) standard. ASHRAE, together with the American National Standards Institute (ANSI) and the Illuminating Engineering Society (IES), published ASHRAE 90.1-2022. The new standard is the latest in a long series of updates spanning many years. In fact, the original ASHRAE standard was published in 1975. Since then, multiple editions have been adopted throughout the United States, with each standard containing increasingly stringent requirements. Though U.S. states have yet to adopt the 2022 standard, there are some important updates that will undoubtedly set the trend for future energy code cycles.

The International Code Council (ICC) has also been busy at work with the latest edition of its model code, International Energy Conservation Code (IECC) 2024. I will cover that in more detail in the IECC 2024 section of this article, but for now it is important to note that ASHRAE and IECC have different 3-year cycles, and IECC follows behind ASHRAE by 2 years. For example, IECC 2021 references ASHRAE 90.1-2019, and IECC 2018 references ASHRAE 90.1-2016. Additionally, IECC offers less choice than ASHRAE 90.1. For example, ASHRAE offers a semi-heated space option; IECC does not. This means that IECC is ultimately a more stringent code than the ASHRAE standard.

ASHRAE 90.1-2022: What You Should Know

According to ASHRAE Standing Standard Project Committee 90.1 Chair Don Brundage, updates in the most recent standard are designed to address the demand for “reduced energy use and carbon emissions.” Important updates in the 90.1-2022 standard include:

- A minimum prescriptive requirement for on-site renewable energy;

- An optional mechanical system performance path, allowing HVAC system efficiency tradeoffs based on the new total system performance ratio metric;

- New energy credit requirements for a customized approach to improving energy efficiency;

- New informative guidance for using carbon emissions, site energy, or source energy as alternative performance metrics to the current energy cost metric;

- Significant efficiency increases in the integrated energy efficiency ratio (IEER) for commercial rooftops and a new seasonal energy efficiency ratio 2 (SEER2)/heating seasonal performance factor 2 (HSPF2) metric for <65K-sized air-cooled heat pumps; and

- New requirements to address the impacts of thermal bridging.

From our perspective in the insulation industry, we are most concerned with the updates pertaining to thermal bridging, which occurs when a more conductive element (i.e., something with a poor insulating value) creates an easy pathway for heat flow across a thermal barrier. The results of thermal bridging include heat loss and increased energy costs, in addition to the potential for condensation, which can have major detrimental impacts on both the building envelope and the structural framing members in a metal building application. ASHRAE 90.1-2022 provides the performance requirements for mitigated linear and point thermal bridges in Section 5.5.5, “Linear Thermal Bridges and Point Thermal Bridges.”

International Energy Conservation Code 2024 Update Established in 1994 to develop a single set of national model construction codes, the ICC is a private, nongovernmental organization responsible for the development of the IECC. After nearly 2 years of development, including a lengthy public comment period, the ICC has concluded development of the latest edition of the code, IECC 2024. Both the residential and the commercial codes are now final1 and are expected to be published in the near future.

Before we review what to expect from the newest code, it is important to note that IECC 2024 marks a major shift in the code development process. After more than 3 decades of a code process, the ICC voted to shift to a standards process.2 In the past, ICC developed the code and allowed for public comment. IECC 2024, however, was developed by residential and commercial consensus committees, which included industry experts and code officials from various sectors. The new process follows ANSI development procedures3 and took into account proposals received during an open-call period, which commenced in June 2023. The new ANSI-approved ICC consensus procedures will be utilized to develop all future I-Codes.

Compared to its 2021 predecessor, IECC 2024 is expected to improve energy efficiency by approximately 6.5% for residential buildings and 10% for commercial buildings. The major change those in the metal building industry should be mindful of pertains to air barrier testing. An air barrier is a material or system of materials designed to reduce uncontrolled air leakage and air infiltration through a building’s thermal envelope. The thermal

envelope separates conditioned space and outdoor air. An air barrier can technically be composed of different types of material and/or coatings, such as polyolefin. An air barrier can be placed on the interior side, exterior side, somewhere within assemblies composing the envelope, or any combination thereof.

Air barriers were made mandatory in IECC 2015/ASHRAE 90.1-2013, and IECC 2024 takes compliance a step further by reducing the allowable air leakage rate in the building envelope to 0.25 cfm/ft2. This translates to less unwanted air leakage and air infiltration

in the building envelope, and greater energy efficiency. The model codes have trended toward increasingly stringent air barrier requirements over the years, and IECC 2024 is

no exception.

IECC 2021: The Talk of the Town

While technically not the newest energy code, IECC 2021 is the most widely adopted code. Several states have adopted it in the past 6 months alone, so it is worth a review. To make things easy, we will compare IECC 2021/ASHRAE 90.1-2019 to IECC 2018/ASHRAE 90.1-2016.

One of the larger changes falls in the air barrier category. While air barriers were made mandatory in the IECC 2015/ASHRAE 90.1-2013 code cycle, never before were air barriers required to be verified. That all changed in IECC 2021/ASHRAE 90.1-2019, which requires the continuous air barrier to be verified by a code official, a registered design professional, or an approved agency in accordance with the following:

- A review of the construction documents and other supporting data shall be conducted to assess compliance with the requirements in Sections C402.5.1.

- Inspection of continuous air barrier components and assemblies shall be conducted during construction, while the air barrier is still accessible for inspection and repair, to verify compliance with the requirements of Sections C402.5.1.3 and C402.5.1.4.

- A final commissioning report shall be provided for inspections completed by the registered design professional or approved agency. The commissioning report shall be provided to the building owner.

Other notable changes in IECC 2021 include:

- More stringent air sealing and blower door testing requirements;

- Mechanical systems updates, updated equipment efficiency requirements,

and refinement of energy recovery ventilation requirements; - A more stringent requirement for lighting systems, such as increased lighting

efficiency and decreased lighting power densities requirements; and - A requirement for electric vehicle (EV)-capable or ready charging stations with

commercial buildings.

States That Have Adopted IECC 2021, ASHRAE 90.1-2019, or a State-Specific Code Modeled after IECC 2021/ASHRAE 90.1-2019

As of August 2024, the following states (plus the District of Columbia) have adopted IECC 2021 or ASHRAE 90.1-2019, or a state-specific code modeled after either IECC 2021 or ASHRAE 90.1-2019:

- California

- Colorado

- Connecticut

- Delaware

- District of Columbia

- Florida

- Illinois

- Maryland

- Massachusetts

- Minnesota

- Montana

- New Jersey

- New Mexico

- North Dakota

- Ohio

- Oregon

- Utah

- Vermont

- Virginia

- Washington

The Big Question: “What Do I Need to Meet Code?”

As we move toward more complexity in each code cycle, this longstanding question

will only become more common. As simple as the question is, it is difficult to answer. In short, the compliance path I recommend most often is the prescriptive approach. Per the U.S. Department of Energy, the prescriptive approach includes “requirements that either must be met by every building design, or if the requirement is not met, a tradeoff can be made to make up for not meeting that requirement.” In other words, you must meet all U-values of the roof, walls, foundation, and fenestrations. If a tradeoff is indeed needed in the end, the quoted price has covered any changes.

Some other areas of the building envelope we should take care to address come from the International Building Code—specifically, the structural code. The important section

to review is Section 1402.2: Weather Protection, which covers weather-resistive barriers

in exterior walls. If the metal building wall panel supplier has not tested their panels

per ASTM E331, compliance can be difficult. ASTM E331 is the exemption for having to

create a wall cavity designed with flashings and a means for draining water that enters

the assembly.

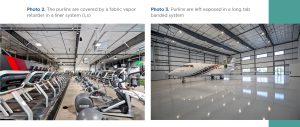

In order to meet the stricter insulation requirements of the last few code cycles, double-layer filled cavity systems have become the standard. The two most common include liner systems and long tab banded systems. Liner systems are private labeled and must meet ASHRAE’s requirements in order to be defined as a liner system (Ls). Long tab banded systems are usually non-proprietary and meet the specifications of a filled cavity (Fc) system.

Both systems provide High-R insulation to help meet stringent energy codes. One key difference is that certain banded liner systems also qualify as OSHA-compliant fall protection systems. Most long tab banded systems typically do not offer fall protection. Both options fulfill the metal building insulation U-value code requirements, so the system selected boils down to budget and preference.

In a banded liner system, large panels of fabric or other vapor retarder material is supported by banding and installed underneath the purlins. Multiple layers of unfaced and/or faced (air barrier) metal building insulation is installed on top of the supporting fabric and banding filling the cavity. The purlins are covered by the fabric vapor retarder in a banded liner system (see Photo 2).

A long tab banded system is a single- or multilayer filled cavity system where the first layer is laminated metal building insulation installed parallel and between the purlin space. The long tab vapor retarder is joined or seamed on top of the purlins. A second layer of unfaced insulation may be placed on top of the first layer, perpendicular to the purlins. Banding on the bottom of the purlins provides support. In a long tab banded system, the purlins are left exposed (see Photo 3).

The Bottom Line

The code cycle changes that are either here or coming soon to your state are, without a doubt, challenging to say the least. However, the newest code changes mean more efficient buildings and more innovative solutions that have greater potential to save end users money.

Online Sources:

1: www.greenbuildinglawupdate.com/2024/04/articles/codes-and-regulations/2024-iecc-is-final-after-addressing-preemption-issues

2: https://support.iccsafe.org/article-categories/iecc-development-process

3: www.iccsafe.org/wp-content/uploads/21-20411_CORP_072121_IECC_Committee_Procedures_FLR_v5_revSH-Reformat.pdf