NIA Contractor Members Discuss System Design: Gribbins Insulation & Scaffolding

This Series Features the Participants of the Inaugural Insulation Project Art Gallery

Showcase and Competition

NIA is proud of the professionalism, creativity, and artistry of our Contractor members. To celebrate the craftsmanship of NIA mechanical and industrial insulation contractors, in 2023 we unveiled the first-ever NIA Insulation Project Art Gallery Showcase and Competition. We invited all NIA insulation contractors to submit photographs and a brief description of projects representing their most creative and artistic efforts. At Fall Summit, we posted all the submissions anonymously, and attendees voted for the top three projects in terms of number of parts insulated, aesthetics, difficulty of installation, and well-installed application. As a regular column, we have profiled the projects submitted, focusing this month on Gribbins Insulation & Scaffolding. We encourage NIA Contractor members to participate in the Insulation Project Art Gallery Showcase and Competition, and possibly be featured in future articles.

PROJECT SNAPSHOT

- Hot Oil Tank – Polyisocyanurate, Dow

- Horizontal Vessels – Mineral Fiber, ROCKWOOL ROXUL

- Hot Oil Tank – 0.024 Aluminum, RIDGLOK® Pre-Fabricated

- Panel System

- Horizontal Vessels – 0.024 Aluminum Sheeting, RIDGLOK

- Pre-Fabricated Panel System

- Hot Oil Tank – Cable Design, Locking Seam Panels, RIDGLOK

- Removable Insulation Covers, Fit Tight Covers

- Fasteners – Aluminum Banding, Screws, Pins

Project Description and Goals

The project involved reconditioning an existing oil tank and insulation of newly installed horizontal tanks and piping at a petroleum plant. Gribbins was responsible for installing insulation and lagging on two horizontal vessels, as well as installing a prefabricated insulated vertical panel system on a crude oil tank.

Project goals were heat conservation and personnel protection. For personnel safety, insulation was required to bring the outside surface temperature of the system below OSHA maximum limits.

Challenges

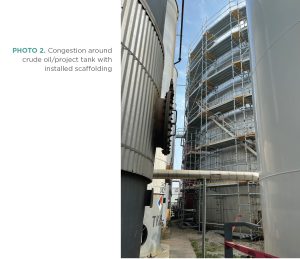

The project presented several physical challenges, one of which was site congestion. As shown in Photos 1 and 2, the crude oil tank to be insulated was virtually surrounded by obstacles, including adjacent tanks, motors, pumps, and stairs. The Gribbins insulation crews needed 100% hands-on access to the tank, while maintaining 8 to 12 inches of clearance from the face. This required a highly skilled team to design and construct scaffolding around the tank for safe access. For this aspect of the project, Gribbins was a logical choice, as industrial and commercial scaffolding is a core capability of the company, which has its own scaffolding division.

Site crowding also meant there was limited space for storage of materials and tools (see Photo 3), which required coordination among the multiple trades working on site. Gribbins was able to create temporary material storage on the scaffolding while working on the tank head (see Photo 4).

In addition, the weather presented a physical challenge: extreme heat. Project Foreman Bill White notes, “The biggest obstacle we faced was beating the heat/humidity and keeping our guys hydrated and happy in direct sunlight all day while wearing fire-retardant clothing.” To accomplish that, the team followed the tenets of the company’s safety program, fending off heat exhaustion and other complications by scheduling frequent breaks, making hydration a priority, and covering the topic in its routine on-site safety coordination meetings. As Gribbins Safety Director Adam Mayer explains, “With heat being our major obstacle, we provided our employees with proper training on how to recognize and identify the signs/symptoms related to heat stress/exposure. We mitigated heat exposure by requiring employees to take additional breaks throughout the shift and provided ample shaded and air-conditioned areas on site. Additionally, we supplied workers with cold water and hydration drinks to replace electrolytes, fluids, and sugars.”

Finally, along with the physical challenges, the customer described an additional issue they hoped the installation could address: Workers would need access to the interior of the large tank periodically for maintenance inspections.

The Gribbins Solution

As noted above, the project involved both new construction (two horizontal vessels/deaerator tanks) and the reconditioning of an existing hot oil storage tank. Although both elements were insulation installations, the differences between the structures and their applications meant that different approaches—and different solutions—were required. Gribbins Project Foremen Bill White and Rick Champell made sure that both sets of requirements were met.

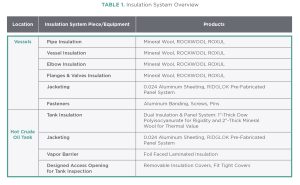

Table 1 offers an overview of insulation system components, as well as product types and brands used.

Horizontal Vessels – New Construction

To address the customer’s goals for the horizontal vessels, Gribbins installed mineral wool insulation for heat conservation under 0.024 aluminum jacketing. At that thickness, the aluminum provided protection and support for the insulation underneath, while also providing aesthetic appeal. Banding was used for securement on the body jacketing, and screws with washers were used on the heads. Photos 5 through 7 show the results of the installation.

Hot Oil Storage Tank – Reconditioning

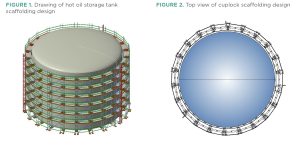

This part of the project required not only expertise in insulation installation but also in scaffolding design, installation, safe use, and dismantling. Gribbins uses industry-specific software to assist in scaffold design, considering critical factors including site conditions, access points, load capacity, and work scope. For this job, they utilized a cuplock scaffolding system for its quick assembly and versatility. The modular design, combined with the unique cup and blade locking mechanism, allows for rapid installation and easy customization to suit a variety of structure heights, shapes, and sizes. Figures 1 and 2 show the design.

Of course, design is just the first step. Gribbins maintains a team of trained, professional scaffold erectors qualified to assemble and maintain scaffolding safely during project performance, and then dismantle and remove it safely once the job is finished. Photos 8 and 9 show how Gribbins used the scaffolding to complete the complicated installation.

For the hot oil tank, Gribbins installed a dual system: polyisocyanurate insulation to limit heat transfer, with the same pre-fabricated RIDGLOK 0.024 aluminum sheet jacket. Richard Daugherty, Industrial Accounts Manager with Gribbins, explains, “Utilizing tank panels offers numerous benefits. They are less labor intensive, are cost-effective, and provide a longevity of up to 12 years for the insulation panel system.” These benefits notwithstanding, installation was not simple. As Foreman Bill White puts it, after the extreme heat, “The next challenge was getting the panels in place, then stacking the second layer and aligning the laps properly using pulleys, ropes, clamps, and good old-fashioned teamwork and communication.” Photos 10 and 11 show what the system looked like as it was being installed, giving a clear picture of why experienced, trained crews were critical to getting the job done safely and correctly.

To accommodate the additional need for worker access to the tank interior without compromising or interfering with the RIDGLOK insulation system, Gribbins coordinated with the customer to have a 4” C-Channel over a 10’ x 10’ opening, shown in Photo 12. Gribbins then had Fit Tight Covers removable insulation covers fabricated for the opening.

Safety Focus

Between the complexity of the scaffolding work and the extreme heat, this project could have been high risk for on-the-job injury or illness. A Platinum-Level NIA Safety Excellence Award winner for the past 5 years running, and certified by the Coalition for Construction Safety, Gribbins counts safety among its core values (along with integrity, quality, and service). Company founder, Jim Gribbins, was ahead of his time in 1999 when he hired a Safety Director. Now, the company has two full-time professional safety personnel in its safety department: the Safety Director and a Safety Coordinator. They spend the majority of their time on jobsites, working with project managers, supervisors, and crews to ensure that everyone is focused on safety in the performance of their work. The company’s many safety awards are truly earned in the field, on projects like this one, where Gribbins employees perform their tasks under a range of challenging conditions safely and efficiently.

Project Takeaways

- Safety = Quality and Efficiency

Adhering to safety standards does not mean sacrificing efficiency. Gribbins project foremen observe that the crews’ ability to follow the instructions and standards provided actually facilitated on-time delivery of a high-quality long-term result. - The Value of a Trusted Professional

Working with a professional contractor you can trust yields benefits all through the process. In this case, consulting with Gribbins in design of the tank access point allowed the customer to get the opening for routine maintenance they need without compromising the integrity of the insulation system. Additionally, this project required not only expertise in insulation installation, but also the skills and experience to design, construct, use, and dismantle the scaffolding needed for the install. - Communication Is Vital to Project Success

Communication should include all parties involved—e.g., engineers and owners consulting with the insulation contractor on how to meet design objectives; holding pre-construction meetings with all contractors before a project starts to ensure proper scheduling and job execution; and incorporating continued communication throughout project performance to identify and mitigate any potential risks early and keep the project running smoothly.

As Gribbins President Brian Willett sums it up, “This project exemplifies our commitment to delivering top-notch insulation solutions for various industries, thereby contributing to energy efficiency and the well-being of workers. The work performed on vessels and tanks stands as a testament to our dedication to safety, quality, and efficiency in the field.”

Strength in Numbers

- Fit Tight Covers

www.fittightcovers.com - MC&I Inc. (RIDGLOK® Panel Insulation Systems for Storage Tanks) https://tinyurl.com/y6ncv3yh

- ROCKWOOL (ROXUL Mineral Fiber Insulation)

www.rockwool.com/north-america

About Gribbins Insulation & Scaffolding

Founded in 1985, Gribbins Insulation & Scaffolding has grown into a leading commercial and industrial mechanical insulation and scaffolding contractor. The company specializes in insulating mechanical and process systems—such as piping, ductwork, and special equipment—for a wide variety of facilities, including hospitals, schools, power plants, and manufacturing buildings. To better serve its customers, and meet their growing needs, Gribbins launched its scaffolding division in 2021.

Integrity, quality, safety, and service are at the core of everything they do. The company’s mission is to maximize customer satisfaction by providing the highest level of safety, quality, and productivity, leading to optimum employee fulfillment and company profit.

With multiple locations across Indiana, Kentucky, Tennessee, Illinois, and Ohio, Gribbins primarily operates throughout the Midwest, although the company’s extensive project portfolio spans states including Texas, Michigan, Kansas, Missouri, Iowa, Wisconsin, Pennsylvania, West Virginia, Alabama, Louisiana, North Carolina, Florida, and even

the Bahamas.

For more information, please visit www.gribbins.com/about.