Mineral Wool with Durable Corrosion Inhibitor Provides Protection from the Costs and Risks of Corrosion under Insulation

Corrosion under insulation (CUI) is a multi-factorial problem, with many causes and no single solution. For any CUI event, if water can be kept at bay, the resulting reduction in the metal’s exposure to water should have tangible benefits in mitigating CUI. Water is tough to keep out of an insulation system, as cracks in the cladding and gaps in the insulation can form over time.

Relying on just one line of defense, such as water repellency, can leave systems vulnerable when water eventually finds its way under the insulation. Using a corrosion inhibitor provides another means of defense against the dangers of CUI.

This article presents the durability of mineral wool with an integral corrosion inhibitor at various operating temperatures using the ASTM C1617 standard corrosion test method. Also, a full-scale insulated and jacketed heated pipe CUI simulation test was performed per the ASTM G189 standard to document the corrosion mitigation performance of mineral wool with corrosion inhibitor when exposed to a water volume equivalent to 15 times the annual rainwater for Houston, Texas, at a 1% infiltration rate. Corrosion-inhibiting mechanisms are discussed, and how they can modify the environment around steel substrates to influence corrosion rates.

The global growth of industrialization and the ongoing need for heavily industrialized processing plants that produce energy, chemicals, food, and other products have become critical to our daily lives. These systems rely on vast networks of high-temperature piping and equipment that are prone to CUI.

CUI is an aggressive, localized corrosion phenomenon arising from water migrating through joints in the insulation system or via damaged areas to reach the metal surfaces of pipes and other process equipment. In many facilities, CUI has dangerous and costly consequences if not properly addressed, including an increased risk of heat loss, unplanned downtime, leaks, and spills. The results include reduced plant output and profitability, as well as greater threats to the health and safety of plant personnel and the surrounding environment.

Corrosion can be triggered and aggravated in many ways, which is why there is no one-size-fits-all solution. Although there are many causes of corrosion, there are three common contributing factors: unprotected metal, oxygen, and water. Most CUI mitigation solutions focus on protecting the metal. Recent solutions have focused on improving the water repellency of insulation materials and making these solutions durable at high temperatures. This allows water to be shed away from the insulation, reducing the amount of water the metallic substrate may see, even at temperatures of -4°C to 175°C (25°F to 350°F), where the CUI risk increases.1

A multi-pronged approach to CUI mitigation could benefit this costly problem. The latest CUI mitigation innovation in mineral wool insulation technology comes in the form of a corrosion inhibitor embedded into the inner layer of the insulation, right where it contacts the metal substrate. The inhibitor activates on contact with water and reacts with iron on the steel surface to form a low-solubility, protective film that shields the pipe from corrosive attack. It also buffers the pH of the water that enters the insulation system, making the water less acidic. The effectiveness was studied in previous papers.2, 3 This article reviews testing performed to examine the durability of this corrosion inhibitor.

A series of third-party laboratory tests was commissioned to test the durability of the inhibitor-treated mineral wool insulation in mitigating corrosion in various scenarios:

- Modified ASTM G189 testing for water throughput of 15 times the annual rainfall of Houston, Texas.

- Modified ASTM C1617 testing after heat aging up to 649°C (1,200°F) for 24 hours.

EXPERIMENTAL PROCEDURE

PART 1: Corrosion Testing to Modified ASTM G189 Simulating 15 Times Annual Rainfall of Houston, Texas

ASTM G189-21 is one of many industry-standard corrosion tests, but it is unique in that it is the only ASTM test that uses a full-scale insulated pipe to more closely simulate field conditions.4 This standard is highly adaptable and has many options, as numerous conditions can elicit CUI.

In this particular set of tests, we wanted to study the effects of water exposure similar to those of a rain event. Because it is impractical to run a test for extended periods and ASTM G189 has no provisions on how to accelerate time during testing, the next logical variable to modify was the amount of water the insulation was exposed to during the test. The water volumes used during the test were based on the amount of rainfall received over 15 years on a pipe. It is important to note that this test is not designed to provide insights into the complete corrosion behavior of a real-life, 15-year duration. Many factors would influence CUI, such as time of wetness, leachate chemistry, and insulation aging, to name a few. This study does not delve into these factors, as it only compares the corrosion rates of mineral wool with and without inhibitor when exposed to 15 times the annual rainfall level of Houston, Texas.

Houston was selected due to its proximity to industrial facilities with high instances of CUI. To calculate the volume of water required to simulate rainfall totals for 15 years, the average annual rainfall total for Houston was determined to be 1316.74 mm (51.84 in) based on government information on a 30-year period from 1991–2020.5 This value, which represented the average for one year, was multiplied by 15 to achieve the 15-year rainfall estimate. To get the volume that would land on the pipe, this value was multiplied by the top projected area (length x diameter) of the insulated pipe specimen used in the test. In this case, a 250 mm (9.84 in) long pipe with an outer diameter of 160 mm (6.30 in) was used.

The next step was to estimate how much water would infiltrate the cladding. The amount of rain bypassing the cladding was based on the ASHRAE 160 standard for infiltration rate through metal building cladding, which uses 1% as the estimated percentage.6 The test used a total volume of 7.9 liters (2.1 gal) of water. The test setup generally follows ASTM G189-21, with the following options and modifications:

- Special silicone O-rings replaced PTFE spacers between samples.

- The test equipment and coupons were clamped using a spring compression system to counter the system’s thermal expansion.

- Ringed test coupons with a width of 14.25 mm (0.56 in) were used, compared to the width of 6.35 mm (0.25 in) specified in ASTM G189-21.

- The test duration was modified to 30 days.

- The insulations tested were installed directly on the pipe.

The test standard calls for an annular gap of 6.4 mm (0.25 in) between the insulation and pipe to retain the water. This test was modified to remove this gap for two reasons:

- Most field installations have thermal insulation installed directly on the pipe, without a set annular gap all around the pipe.

- A gap is not necessary to retain water in open-cell insulations like mineral wool, because the water moves into the insulation instead of flowing directly out to the drain. And because the insulation retains the water, a valve was not necessary. This was apparent upon initial water injection, when we observed that water did not exit the system immediately but instead distributed under and through the insulation.

None of the modifications were considered a relaxation of the test method and apparatus described in ASTM G189-21.

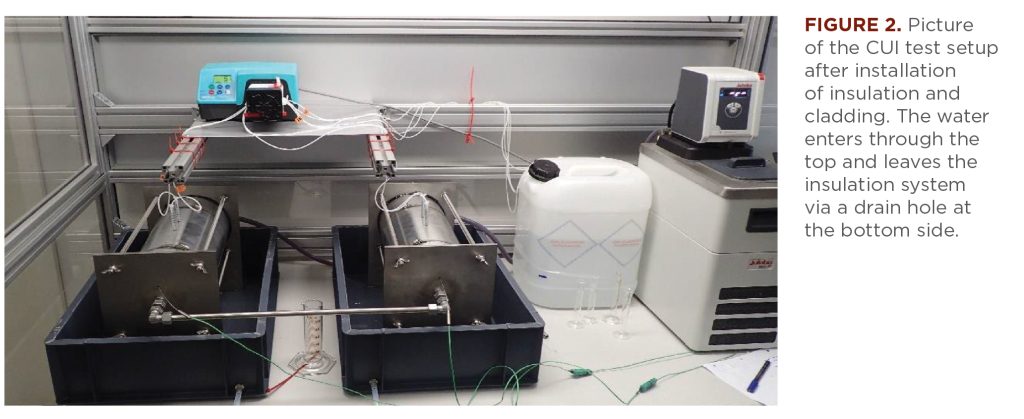

Figures 1 and 2 provide a schematic and photo of the test setup and equipment.

The solution of deionized water was injected through 2 x 4.75-mm (0.187-in) holes drilled down to the pipe surface in the 12 o’clock position. This allowed the solution to be introduced at the interface between the insulation and the pipe surface. A single drain was placed at the 6 o’clock position. The solution was not recirculated, and therefore, none of the inhibitor was redistributed onto the piping. The total volume of water used was 7.9 liters (2.1 gal).

The minimum duration for testing, as per Table 1 in the ASTM G189 standard guide, is listed as 72 hours for a cyclic wet/dry (CWD) scenario. Limitations of the testing equipment presented challenges in pushing the amount of water selected for testing through the CUI cell within 72 hours. As a result, testing was extended to 720 hours. This timing allowed water to slowly drip out of the drain rather than flushing out in a constant stream. This is important as high water throughput may wash away corrosive species.

The water injection regime used an initial boost flow rate of 42.5 ml (1.437 oz) for the first 10 minutes to achieve complete water coverage at the start of the test. The standard specifies that a valve be closed at the drain hole to ensure full water coverage around the pipe at the start of the test.

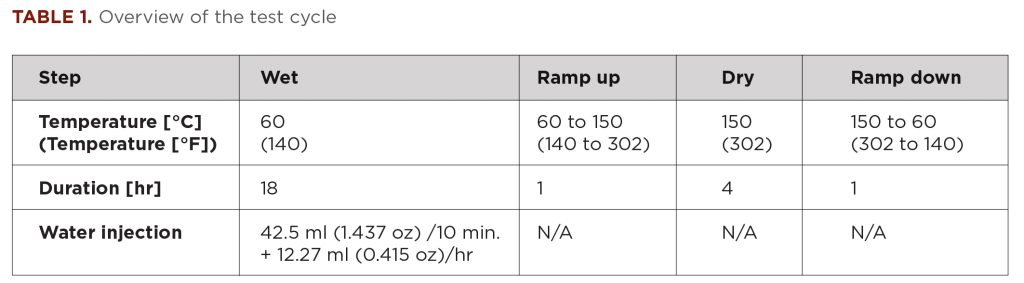

With the insulations tested, no flushing of water was observed through the drain hole during the initial boost period, which negated the requirement for a valve. After the boost flow, a constant 12.27 ml (0.415 oz)/hour was injected to keep water flowing into the system during the wetting cycle of 18 hours. This amounted to 263.33 ml (8.904 oz) per day for a total of 7.9 liters (2.1 gal) over 30 days. Only a few drips per minute of water from the drain hole were observed during the wetting time. Table 1 lists the wet and dry cycle operating temperatures of 60°C (140°F) wet and 150°C (302°F) dry. These values were chosen based on the example conditions for CWD provided in the ASTM G189 standard. This temperature range was also within the greatest likelihood of the CUI zone.

The insulation material was sealed to the test pipe using silicone, creating a 25-cm (9.8-in) long enclosure. The insulation was secured tightly to the pipe surface using stainless steel wire. The outer aluminum jacket was fastened around the insulation using hose clamp bands and sealed longitudinally to the flange ends using silicone. This limited the inlet and exit points for water.

Corrosion measurements were taken using mass loss data (Procedure A) as per the ASTM G189 standard. The mass was recorded at pre- and post-exposure, testing, and cleaning (per practice G1).7 The corrosion rate was then determined using the mass loss data and formula (2) from ASTM G189.

PART 2: High-Temperature Durability Performance of Mineral Wool with Corrosion Inhibitors

The test method selected to determine the CUI mitigation performance of mineral wool with corrosion inhibitors was ASTM C1617-19, “Standard Practice for Quantitative Accelerated Laboratory Evaluation of Extraction Solutions Containing Ions Leached from Thermal Insulation on Aqueous Corrosion of Metals.”8 Testing was completed in a third-party laboratory.

This test used a solution extracted from insulation using the standard test procedure ASTM C871, “Standard Test Methods for Chemical Analysis of Thermal Insulation Materials for Leachable Chloride, Fluoride, Silicate, and Sodium Ions.”9 Ground pieces of insulation were boiled in water and then filtered to produce a solution applied to heated carbon steel coupons over 96 hours. The solution was contained on the coupons using a short PVC pipe adhered to the coupon with silicone. The steel coupon was weighed before and after testing to determine an estimated mass loss corrosion rate (MLCR) measured in mils (thousandths of an inch) per year (MPY).

Testing was always done alongside a control. The standard calls for a solution of distilled water (0 ppm chloride) evaluated along with a 1-ppm and a 5-ppm chloride solution.

The mineral wool with inhibitor insulation was subjected to different heat treatments prior to testing to ASTM C1617. The temperatures selected were 316°C (600°F), 427°C (800°F), 538°C (1,000°F), and 649°C (1,200°F). Heat treatment duration was selected as 24 hours since, typically, loss on ignition (LOI) testing, which is done to determine the weight loss of different elements upon oxidation, varies from a few hours to overnight. (Note: this timing may not be sufficient to fully represent long-term heat aging, and results will vary at different heat aging times and temperatures.)

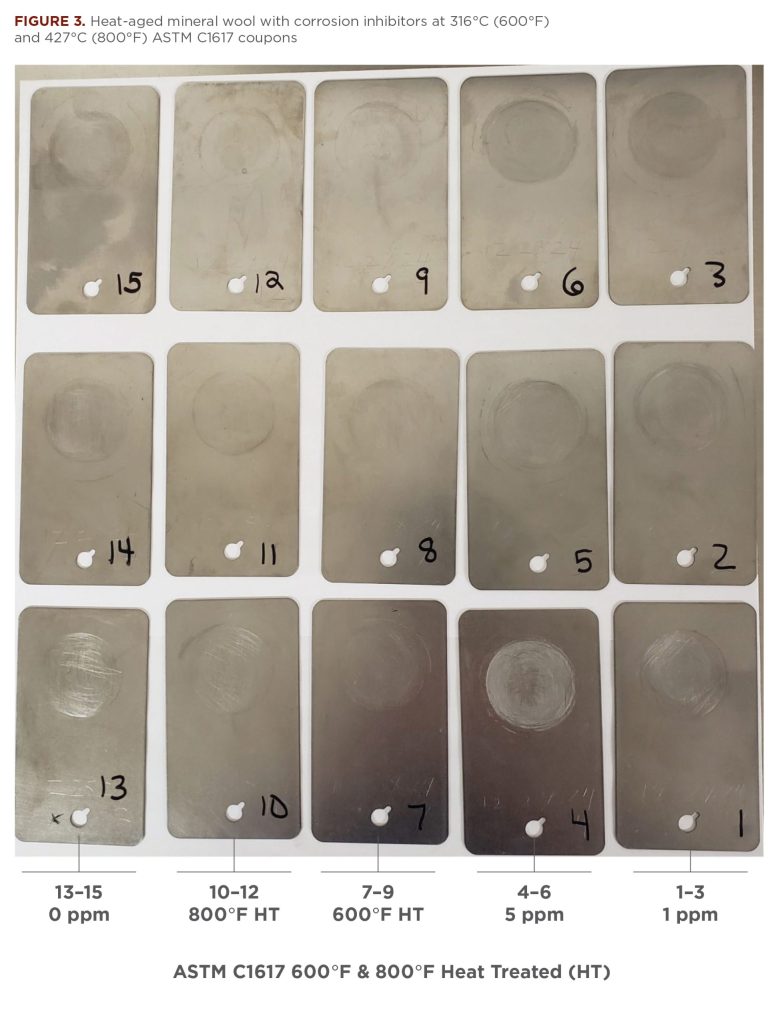

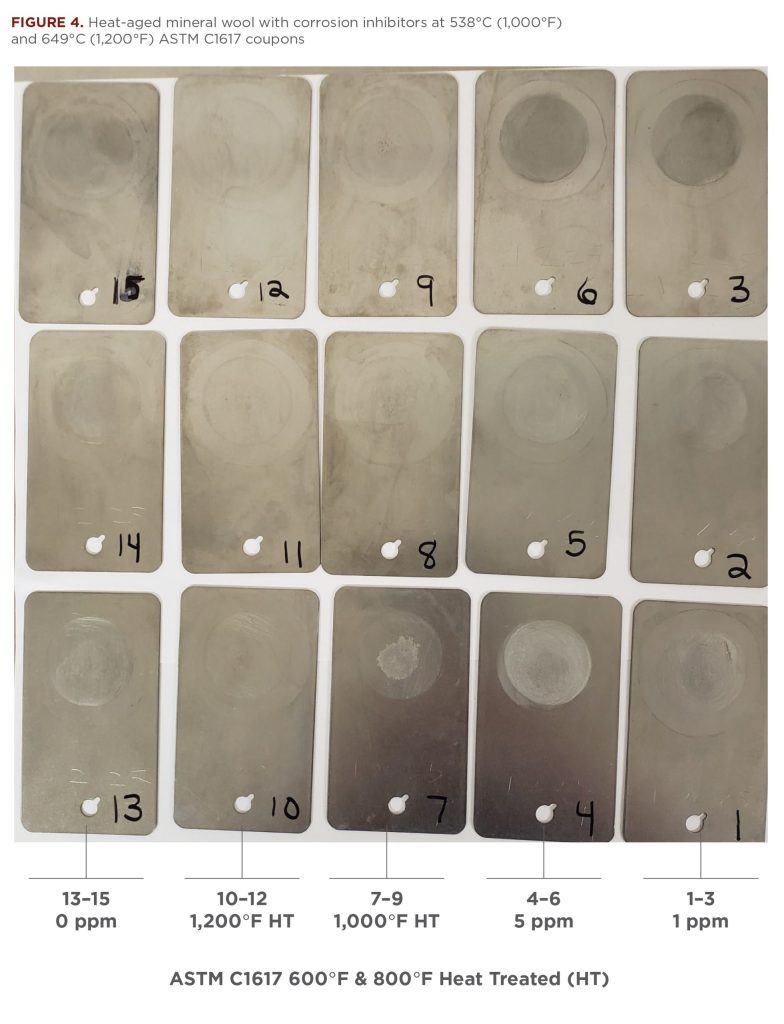

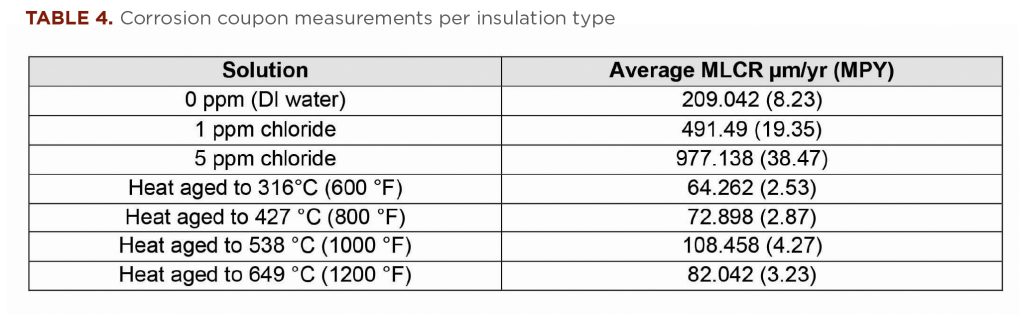

The performance at these temperatures was compared to control samples of 0 ppm, 5 ppm, and 10 ppm chloride solutions. (See Figures 3 and 4).

RESULTS

PART 1: Corrosion Testing to ASTM G189 for Water throughput of 15 Times the Annual Rainfall of Houston, Texas

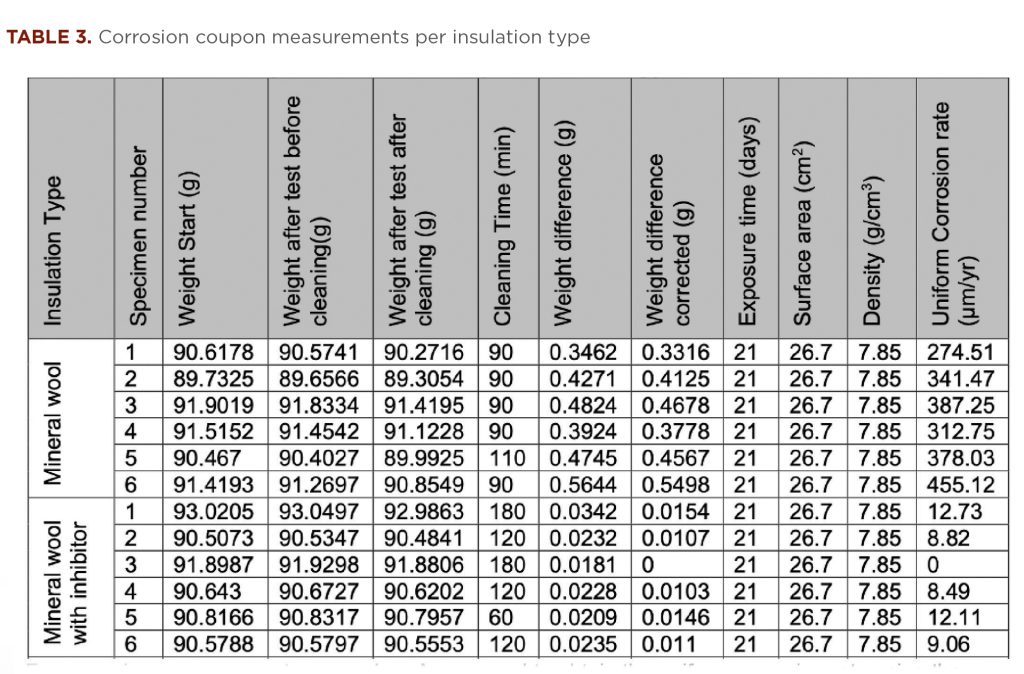

For corrosion measurements, procedure A was used to obtain the uniform corrosion rate using the following formula per ASTM G189.

(“Constant [-]” x “Weight difference, corrected [g]”)/(“Exposed area [cm2]” x “Density [g/cm3]” x “Exposure time [days] x 24 hours/day”) x 10 [mm/cm] x 1000 [µm/mm]

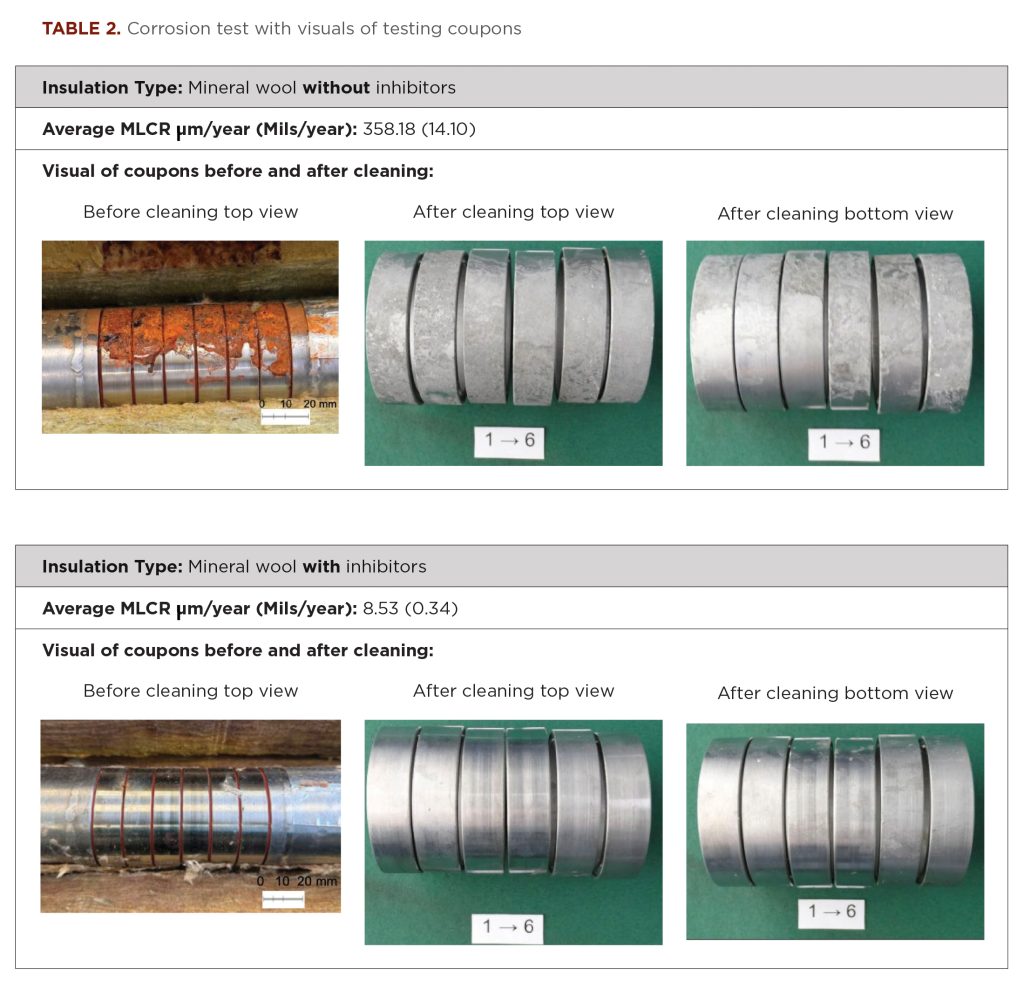

The uniform corrosion rate of the six specimens per insulation type was then averaged and listed in Table 3. Mineral wool without an inhibitor showed corrosion on the top and bottom. For the mineral wool with a corrosion inhibitor, the pipe’s top and bottom sections visually showed similar corrosion.

In terms of an average uniform corrosion rate (the corrosion rate of the entire coupon), the pipe insulated with mineral wool without inhibitors was 358.18 µm/year (14.10 MPY). Mineral wool with inhibitors showed a rate of 8.53 µm/year (0.34 MPY).

In many facilities, CUI has dangerous and costly consequences if not properly addressed, including an increased risk of heat loss, unplanned downtime, leaks, and spills.

PART 2: High-Temperature Durability Performance of Mineral Wool with Corrosion Inhibitors

The results in Table 4 show the corrosion mitigation performance to the standard test ASTM C1617 after heat aging up to 649°C (1200 °F) for mineral wool with corrosion inhibitor, which is the maximum service temperature. The average MLCR when heat-treated at various temperatures up to 649°C (1,200°F) remains below the MLCR of deionized water at 209.042 µm/yr (8.23 MPY). There is very little change in the performance when heat aged at 316°C (600°F) to 649°C (1,200°F). These results indicate that the mineral wool with inhibitor solution has a lower MLCR than clean deionized water. This may be due

to the corrosion inhibitor’s ability to form a film protecting the steel and buffer the pH.

Table 4 also lists the MLCR of 1 ppm and 5 ppm chloride solutions. As expected, the MLCR increases with a higher concentration of chlorides, since chlorides are known to promote corrosion.

The inhibitor’s heat durability stayed consistently below that of deionized water when heated up to 649°C (1,200°F) for 24 hours. This result may change with different heat aging durations and temperatures.

CONCLUSIONS

In testing to ASTM G189, mineral wool with inhibitors maintains superior corrosion protection after exposure to simulated 15 years’ worth of rainfall levels. The mineral wool with inhibitors also showed a consistent MLCR (and a lower MLCR than with deionized water) when heat aged at temperatures from 315°C to 650°C (600°F to 1,200°F).

These results are promising for both existing and new process-intensive facilities that require proven, cost-effective CUI mitigation solutions to improve the safety and long-term productivity of their operations.

REFERENCES

- NACE SP0198-2017, “Control of Corrosion under Thermal Insulation and Fireproofing Materials–A Systems Approach. NACE International

- M.O. Hansen and S.N. Rasmussen, “Improving mineral wool CUI performance–next generation” AMPP Annual Conference + Expo 2023, paper no. 18959 (Denver, CO: AMPP, 2023)

- R. Seto, “Mineral wool CUI mitigation improvements” AMPP Annual Conference + Expo 2024, paper no. 20798 (New Orleans, LA: AMPP, 2024)

- ASTM G189 (2021), “Standard Guide for Laboratory Simulation of Corrosion Under Insulation” (West Conshohocken, PA: ASTM)

- National Weather Service. (n.d.). Climate normals summary for Houston Intercontinental Airport. National Weather Service. www.weather.gov/hgx/climate_iah_normals_summary

- American Society of Heating, Refrigerating and Air-Conditioning Engineers. (2016). Criteria for moisture-control design analysis in buildings (Standard No. 160). ASHRAE

- ASTM G1-03 (2017), “Standard Practice for Preparing, Cleaning, and Evaluating Corrosion Test Specimens” (West Conshohocken, PA: ASTM)

- ASTM C1617 (2019), “Standard Practice for Quantitative Accelerated Laboratory Evaluation of Extraction Solutions Containing Ions Leached from Thermal Insulation on Aqueous Corrosion of Metals” (West Conshohocken, PA: ASTM)

- ASTM C871 (2018), “Standard Test Methods for Chemical Analysis of Thermal Insulation Materials for Leachable Chloride, Fluoride, Silicate, and Sodium Ions”

(West Conshohocken, PA: ASTM)

Images provided by ROCKWOOL Technical Insulation