Ensuring Compliance with COMcheck for Metal Buildings

Background

For many years, metal building insulation was considered condensation control. From the 1960s through the 1990s, there were few performance requirements for insulation and a lack of

cost-effective solutions for constructing buildings with high insulation values. Metal buildings were sold and marketed as low-cost structures that could be constructed quickly; energy

efficiency was not part of the conversation.

As we moved through the mid-1990s, the ASHRAE 90.1 Standard started to require in-place value for metal building insulation. This began some of the first hot box testing of

in‑place/installed thermal values for metal building insulation&and this testing remains in use today. By the end of the 1990s, the ASHRAE 90.1 Standard became more stringent on

the building envelope; by 1998, the International Code Council (ICC) adopted the ASHRAE standard, with certain modifications to make the building envelope standard more exacting.

At the same time, the Department of Energy (DOE) was developing a new compliance tool–COMcheck–to help specifiers, contractors, and other construction professionals find the

building codes for their states, as every state is required to have a Commercial Building Energy Code. COMcheck provides a link for users to determine the current codes in their state, and

lists a contact person who can give them further details and answer any inquiries. COMcheck includes both the ASHRAE standard and the International Energy Conservation Code (IECC). ASHRAE

publishes its standards on a 3-year cycle, and the ICC publishes its codes 2 years after the ASHRAE standard is published. For the most part, the IECC follows ASHRAE’s standards, with

certain changes for higher envelope requirements. Many states began to adopt the ICC’s version of codes, mandating that buildings must comply these standards. It is now fairly common for

states to require a COMcheck report before they will issue a building permit.

FIGURE 3: Job Site Insulation Being Rolled Out

FIGURE 4: Construction Aerial View

The envelope of a building has 6 sides: 4 walls, a roof, and a floor. The floor of a building must be included as part of the envelope. Oftentimes it is not included, which may result

in a certificate that is not adequate, and the building official may not issue a permit. It is important to be detailed when using COMcheck software. Doors, windows, overhead doors, and

any masonry wall areas must be entered correctly to ensure compliance. Reports that leave out these areas often fail to pass applicable codes. Doors, windows, and any component of the

envelope can help the overall COMcheck report. While the performance requirements for these components are stringent in both the ASHRAE 90.1 Standards and the IECC, many commonly available

products surpass the standards. This allows the design professional or builder to utilize the trade-off method and take advantage of these more energy-efficient components.

FIGURE 5: Metal Building Door Installation

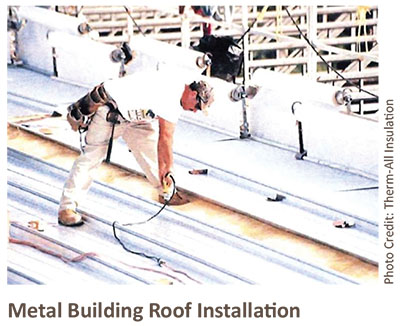

FIGURE 6: Metal Building Roof Installation

FIGURE 7: Metal Building Interior

COMcheck will be an increasingly important tool as the industry seeks to create more energy-efficient buildings. This software can be downloaded or accessed online for free from the DOE

website at www.energycodes.gov/comcheck.

SIDEBAR 1

COMcheck Walkthrough

Before you begin your COMcheck report, you must have all the necessary input information. Most of the information can be found on the architectural drawings and from the manufacturers

of the components for your project. If you are inputting information for a design build project, you may need more performance information. The following instructions describe the process

of completing a COMcheck report for a building envelope for a metal building using the downloadable COMcheck software.

- Follow the link provided on the opening screen of COMcheck to the DOE website (www.energycodes.gov/adoption/states/) and select the state for the project location using the drop-down menu. This screen will

list the current commercial code that has been adopted by the state selected. It is critical to confirm the most up-to-date energy code or standard that has been adopted by the local

jurisdiction for the project location. This screen also gives the name and phone number for each state code official. Calling to confirm is always best, as COMcheck updates may not reflect

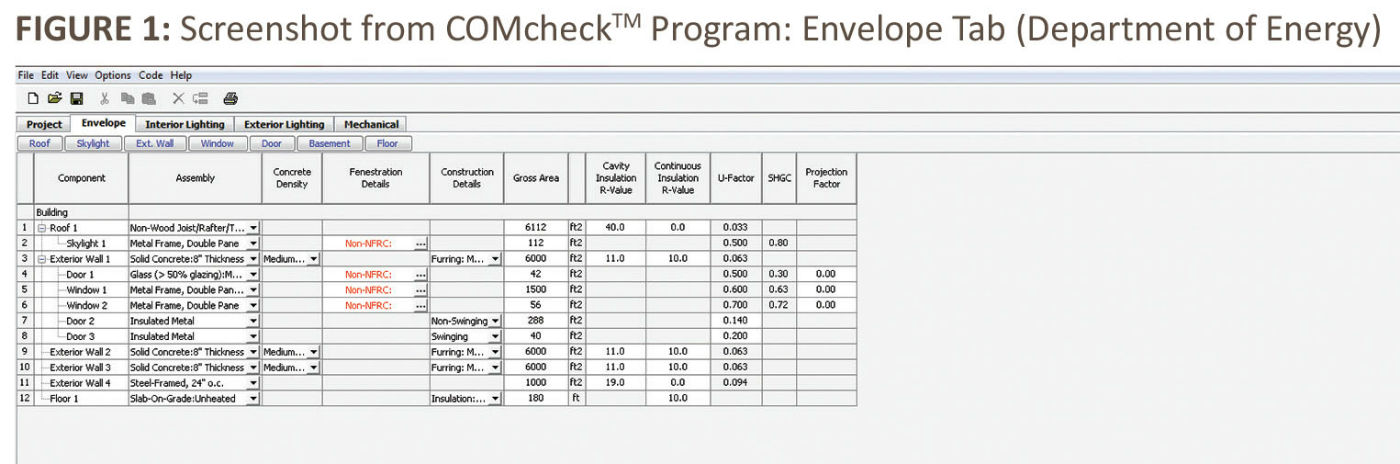

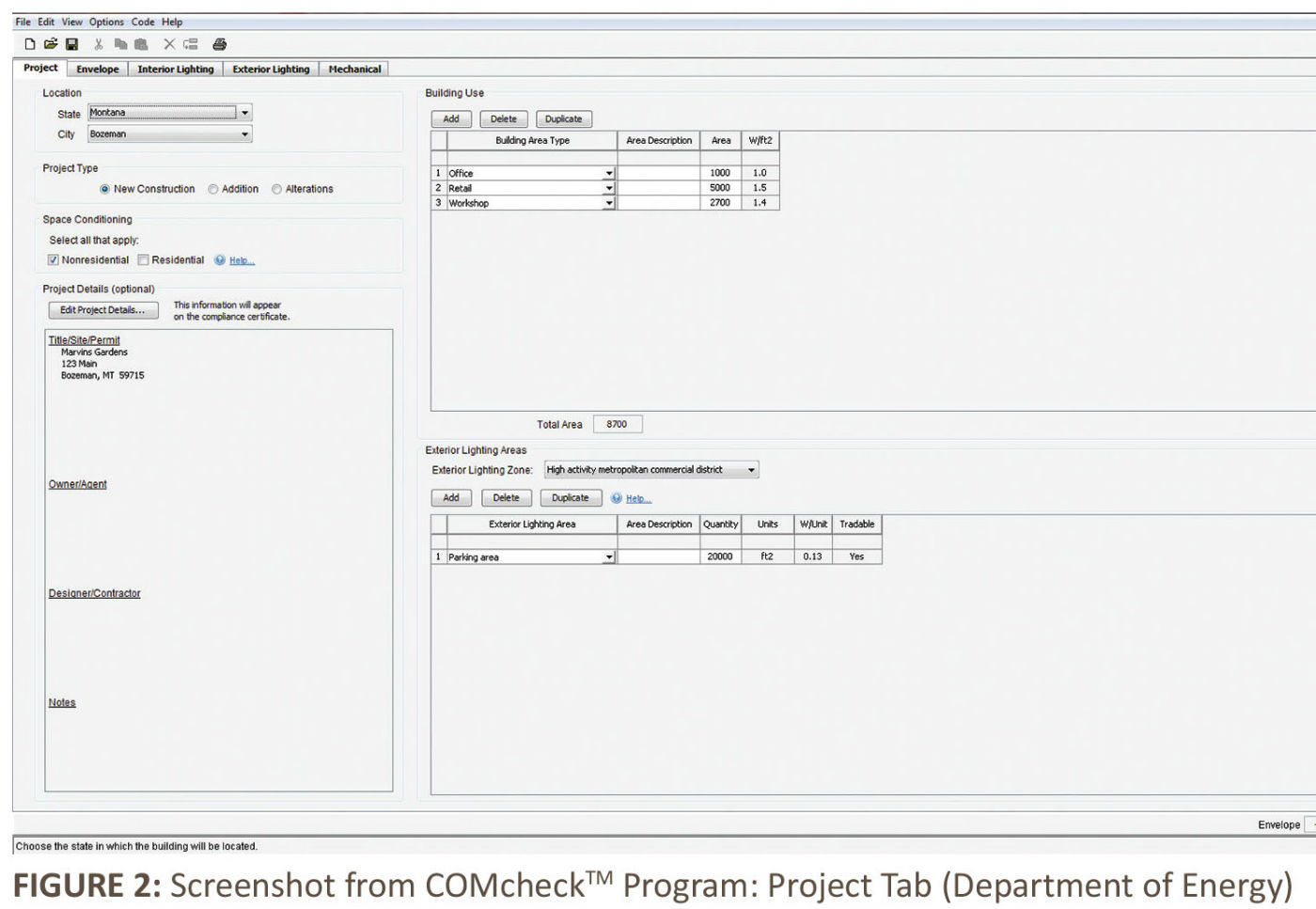

current code cycles in all states. - Return to the COMcheck program, click on the “Project” tab, and then click on the “Code” tab from the top tool bar. From this drop-down menu, select the energy code that was

shown on the DOE state adoption page based on the project location. Fill in the details for the project location; project type; space conditioning; and project details including the

project title, owner, designer, and contractor information. Under the “Building Use” heading, select the building area type from the list of categories provided, and enter the area of the

building. See Figure 2 on page 7 for a screen shot of this tab. - Select the “Envelope” tab. This will give you a series of drop-down menus to put in information about each area of the building: roof, skylight, external wall, internal wall,

window, door, basement, and floor. Next, enter the area and thermal properties of each component or assemblies for the roof, walls, and floor. Keep in mind that the “Other” option should

always be evaluated to maximize design flexibility and cost efficiencies. This process can be relatively straightforward if you have all the information you need regarding the U-factors,

solar heat gain, area measurements, and all roof and wall insulation values in front of you. See Figure 1 on page 7 for a screen shot of this tab. - When all the information is entered, a cell will appear in the lower right portion of the screen showing the percentage by which your building envelope passes or fails to meet

code. A positive number in this cell indicates that the building meets or exceeds code requirement; a negative number indicates the building fails to meet code. - If the envelope fails to meet the selected code, adjustments need to be made using the trade-off method (see Perscriptive vs. Trade-off Approach on page 12), which often will

include the use of the “Other” option. - If any of your inputs appear red, there is an issue with the input.

- If none of your inputs appear red, you can print a certificate of compliance.

After you provide a completed COMcheck report to the town official, a building permit is issued. However, this does not mean that there will not be a final inspection of the building,

so it is crucial to build the envelope specified in the COMCheck report. If you do not follow the specifications and a final inspection discovers discrepancies, you could be forced to

completely redo the installation, which can be time consuming and expensive.

SIDEBAR 2

Perspective vs. Trade-off Approach

Prescriptive Approach

- COMcheck will provide a certificate of code compliance when the prescriptive/default insulation R-values/U-factors are entered into all applicable fields.

- This is limited to values currently shown in the COMcheck database, which may not include the thermal performance of the most up-to-date components and assemblies.

- This also may limit design flexibility.

Trade-off Approach

- This is the approach preferred by many design and construction professionals because it allows flexibility in the building design process.

- The trade-off approach tracks the overall building envelope’s thermal efficiency and allows the designer to “trade-off” (substitute) a better performing (lower U-factor)

component or assembly in one area of the building envelope for a higher performing component or assembly in the same or different part of the building envelope. - This approach allows the user to take advantage of the most current thermal test data available through the use of the “Other” option on the program’s drop-down menu. When the

“Other” option is selected, the user is prompted to enter the U-factor for the proposed system. This option allows the user to take advantage of all thermal test data available, even if

the assembly or component’s U-factors have not yet been included in the program’s drop-down menus. Documentation may be needed to verify the U-factors, which should be available from your

suppliers.