Exploring Insulation Materials: Flexible Aerogel Insulation

Flexible aerogel insulation is a

composite of an amorphous silica-based aerogel cast into a fiber reinforcement.

The fiber reinforcement may consist of a batt, a needled felt blanket, or other

configurations of fibers. The fibers themselves may be inorganic, such as glass

fibers, or organic, such as polyethylene. The flexible aerogel insulation

typically contains hydrophobic agents and may also contain opacifiers.

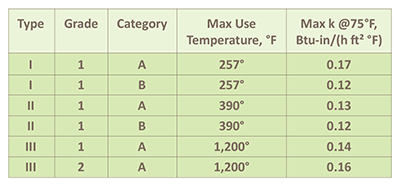

Flexible aerogel insulation is

covered by ASTM C 1728. The standard covers material for operating temperatures

between -321°F and 1,200°F. Materials are classified by use temperature and by

thermal conductivity as follows: (see figure 1)

Type III, Grade 2 conductivities are

tested in pipe configuration.

The standard also contains

requirements for density, compressive resistance, surface burning

characteristics, exothermic temperature rise, linear shrinkage, sag resistance,

water retention, water vapor sorption, flexibility, corrosiveness to steel, and

fungi resistance.

Flexible aerogel insulations are

typically supplied in sheets ranging in thickness from 0.2 to 0.4 inches. Key

applications include original equipment manufacturer, pipeline, vessels, and

equipment in commercial and industrial applications.