A Different Perspective: Corrosion Under Insulation in the Power Industry

Corrosion under insulation (CUI) is an ongoing issue at many power plants. Corrosion can be found under insulation used over boiler walls and hot steam piping, or under insulation for flues, ducts, and air-pollution equipment. To better understand CUI, we must know what corrosion is and what causes it.

The most common and costly type of CUI found at power plants is oxide corrosion. It can be described as either plate or pipe corrosion. They are the same type of corrosion, but the medium they carry makes them different. Both terms refer to corrosion caused by moisture getting to the plate, casing, pipe, or tube (sometimes referred to as substrate).

Plate corrosion refers to corrosion found on the plate that is used to fabricate flues, ducts, air-pollution equipment, and casing that is used to fabricate penthouses and vestibules. These areas have either hot air or hot gas inside. If corrosion causes a leak, it can cause harm; but this can be detected before anyone gets seriously hurt because hot gas or hot air leaks have an unmistakable odor, and there is usually no sudden burst or rupture.

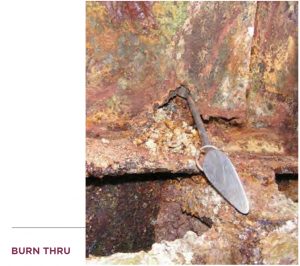

Pipe corrosion refers to corrosion found on boiler wall tubes, boiler trim and drain piping, soot blower piping, headers, downcomers, supplies, risers, steam leads, and the balance of plant piping. These systems have either hot water or steam (saturated and superheated). Unlike plate corrosion, if CUI occurs on these systems, it is in most cases not detected until the pipe or tube bursts. With no warning, a leaking pipe or tube can spray hot steam or water, which can cause injuries and even fatalities to the plant personnel working in the area.

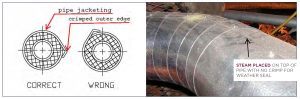

Though insulation cannot prevent or stop water from getting to these areas, insulation can have characteristics that could mitigate or help prevent water incursion. The best prevention includes proper installation of the insulation and an outer covering (e.g., jacketing for piping) that is watertight, to keep external water from ever getting to the insulation. Unfortunately, that is not always easy. For example, the placement of the crimped weather edge on pipe jacketing can make a difference, impacting the effectiveness of efforts to stop CUI.

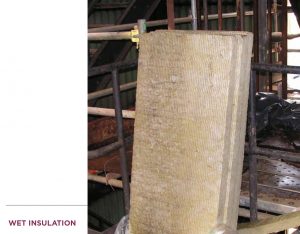

Fortunately, at power plants, the majority of the time temperatures during normal operation are above 230°F, which is approximately the temperature water steams. If water does get into the insulation, it will not be absorbed into the fibers. When a unit is running, the water will steam off. The normal power industry standard requires insulation on any system operating at 150°F and above. This lower temperature is found on such systems as feed water piping systems, some drain and vent piping systems, forced draft fans, and ducts from the forced draft fans to the air heater. These are the systems most vulnerable to external rain and potential CUI.

Obviously, water from external sources like rain is what causes the electrochemical mechanism to occur, which leads to pitting and eventually to holes or cracks on the substrate surface. So what other source(s) can water come from that could get under the insulation?

Treated water is used for boil out, acid cleaning, and chemical cleaning. It is used throughout the power industry.

- Boil out (not to be confused with hydrostatic testing)—A cleaning process used before a new or re-tubed boiler goes online. The inside of the boiler tubes and systems (i.e., superheater tubes) must be cleaned to remove any foreign material that may have gotten inside—such as grease, oils, or even welding material—before the unit can be filled with water to make steam. This type of cleaning uses potable water with an alkaline reagent (soda ash, caustic soda, phosphates, and silicates) pumped inside the tubes to dissolve any grease, oil, or protective coatings from the manufacturing process. The unit is then cooled, and water is removed quickly.

- Acid cleaning —A cleaning process used for boilers that have been in operation. Acid cleaning is used to remove sludge or other corrosion products inside the tubes that may have accumulated over time. Acid cleaning is also used in new boilers prior to boil out to remove original mill scale inside the tubes. The acid is very caustic and must be kept off the outer surface of the tube and removed quickly with solvents.

- Chemical cleaning—A cleaning process used to remove grease that has decomposed into organic acids such as hydrochloric acid, hydrofluoric acid, citric acid, and phosphoric acid. All of these acids are not only bad for the substrate but also can attack insulation.

The water for all the above-mentioned cleaning processes comes from an outside source that requires hooking up to the steam-generating boiler. External leaks may occur at weld locations, or a ruptured process line can spill or spray the chemically treated water onto external surfaces. For boiler tube cleaning, the entry to the boiler will be directly into a boiler’s wall tube or into a header that has a plug or cap. Either way, external insulation is removed to expose the tube or header (and some insulation adjacent to the removed area). In some cases, spillage of the treated water may drip down multiple floors and get into the insulation below. The water may steam away when the unit comes back online, but the organic acids may remain, which can cause CUI.

So, what characteristics do we look for in an insulation material used in the power industry, beyond just its thermal and temperature characteristics?

Insulation can come in many forms and types, but the most common at a power plant are hard block type ASTM C533, type I and II; mineral wool board ASTM C612, type IVB; mineral wool blanket ASTM C592; preformed pipe insulation type ASTM C533, type II: ceramic fiber board and blanket; and fiber glass boards ASTM 612. All have different thermal characteristics, but the other desired characteristics are the same:

- Resistance to moisture, so as to not create or retain water (low or no porosity);

- Reasonably low conductivity that will not increase appreciably when in service;

- Sufficient mechanical strength to withstand shipping, application, and handling;

- Low shrinkage when heated;

- Good resistance to disintegration or settling due to vibration, even after prolonged service at operating temperatures; and

- The ability to retain structural strength during exposure to operating temperatures.

Obviously, number 1 is most important to preventing CUI. If you read insulation data sheets for the types of insulation mentioned earlier, all are resistant to moisture. The insulation manufacturers do a 24-hour “soak test” (ASTM C210) to verify that their material retains its thermal characteristics after the insulation has dried. If any of these insulating materials get exposed to high temperatures (above 250°F), the water is steamed away. The insulation material will still retain its insulating properties regardless of how many times this is repeated, as long as the insulation is held in a sandwich construction, which is a system where the insulation is in direct contact both with the outer finish (lagging or jacketing) and against the pipe, tube, plate, or casing. In some cases, an inner support system, such as 22-gauge corrugated inner lagging or road mesh, is used over external stiffeners for insulation support. However, the large-

opening configuration of road mesh makes it undesirable for an inner support if a sandwich construction is required.1

CUI is preventable, and prevention begins at insulation installation. The best way to prevent CUI is to ensure a properly installed insulation and outer finish (lagging or jacketing), installed in a sandwich-type construction. The next step is frequent plant inspections including both the inside and the outside of the boiler. Preventing CUI requires continued careful attention to insulation and lagging, and pipe-jacketed systems, and being careful during boil out and chemical cleaning processes. Remember: It is always cheaper to replace your insulation than it is to repair or replace the substrate-corroded area.

Reference

- A sandwich construction is used to prevent loss of insulation material after binder burnout due to vibrations associated with normal boiler operation. The open spaces on road mesh are too large to prevent loss of insulation material over time.