Energy Efficiency in Insulation Systems

Let’s look into the industrial and commercial insulation realm. The goal of insulation is to keep the heat in the system as long as possible—or at least until it’s delivered to its useful destination. Insulation’s effectiveness is tied in good portion to its efficiency, which requires that all material be installed correctly. Once it is in place, the efficiency is tied to proper maintenance, managing product aging, and remediation.

One of the tools that can address both sides of these issues is a thermal camera. Imaging insulation for effective and proper installation eliminates efficiency issues up front. Correspondingly, thermal imaging an existing system for wear or damage can help managers make effective remediation or replacement decisions. Our discussion will revolve around both of these processes and the knowledge needed to effectively utilize a thermal camera in these 2 application scenarios.

To measure installation effectiveness, you would have the mechanical contractors put the insulation in place in the proscribed manner. Field conditions sometimes bring about unintentional and maybe intentional inefficiencies—if you have not enlisted an experienced contractor—when installing insulation. It can be difficult and expensive to fix installation issues after the fact, which is why it’s so important to hire skilled mechanical insulation contractors.

As an example, consider Figure 1. The piping has a cover on it and would not look any different to the naked eye, but the thermal camera demonstrates that the insulation at the corner is less efficient than the straight sections. Insulating around bends requires special attention to prevent this type of heat loss. This type of inefficiency costs the building owners in 2 ways: first because the system has to work harder to make up for the heat loss, and also in the cooling to remove the excess heat from the surrounding building environment. While the camera easily illustrates the issue, the solution may not be so simple.

Another common problem area is support saddles. They attach directly to the process piping and the energy conducts into the saddle and the hanger. As the infrared image in Figure 2 shows, the situation has a couple of issues. One is a safety issue, in that the hanger and support are very hot and present burn potential to any unsuspecting worker. The other concern is the loss of energy from this saddle—how much energy can be lost from this type of issue?

Assuming this is a approximately a half square foot of area, a quick calculation shows that this is radiating and convecting about 80 watts/hr or 273 Btu/hr. That would mean in one day, this one saddle is putting 6500 Btu/hr into this space. As an example, let’s say there are 50 saddles on this pipe run—that would make the loss equal approximately 325,000 Btu per day (plus the cooling to remove it at 25 tons.) Assuming the cost of gas energy is around $1.10 per therm, the energy savings from fixing this issue would be more than $1,500 per year.

In the insulation industry, it is typical to run heat-loss calculations on a pipe under different insulation types to find the right cost to efficiency return on investment (ROI). Thermal imaging can be a valuable tool in this process to find damage or inefficiencies that cannot be seen by the naked eye, and help determine if an immediate repair is needed to prevent any issues, or if a future remediation would be more cost effective.

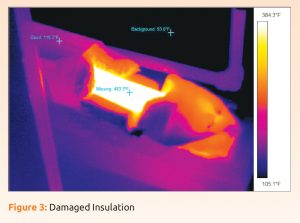

Taking an obviously damaged section, see Figure 3, it is possible to calculate the loss and determine the payback for repair. Assuming a 2” pipe with a surface temperature of 483°F and ambient temperature of 94°F, the bare pipe heat loss is about 1478 Btu/hr/ft. With 2” of mineral wool insulation, the heat loss drops to about 74 BTU/hr/ft, giving a net heat loss of 1404 Btu/hr/ft. For a one foot length, this gives a net heat loss of about 12.3 MBtu annually. The industrial price of natural gas is about $4.02/mcf. At an energy efficiency of 0.40, this gives a cost of about $10/Btu, resulting in an annual cost of about $123/ft. Cooling is about $10/MBtu, so if the environment needed to be cooled, double the cost to $246/ft. This information can be factored into a maintenance plan and decisions for repair can be made.

As demonstrated above, thermal cameras can find and identify the inefficiencies in a system. Taking measurements and various parameters to extract meaningful information can assist in quantifying these issues into meaningful cost and repair numbers that can help facility owners make repair and maintenance decisions.

Copyright Statement

This article was published in the September 2017 issue of Insulation Outlook magazine. Copyright © 2017 National Insulation Association. All rights reserved. The contents of this website and Insulation Outlook magazine may not be reproduced in any means, in whole or in part, without the prior written permission of the publisher and NIA. Any unauthorized duplication is strictly prohibited and would violate NIA’s copyright and may violate other copyright agreements that NIA has with authors and partners. Contact publisher@insulation.org to reprint or reproduce this content.