Mechanical Insulation Simple Calculators: A Guide to the Financial Returns and Personnel Protection Calculators

As a part of

efforts by the Department of Energy’s Advanced Manufacturing Office to improve

the energy efficiency of the U.S. industrial and commercial sectors, the

National Insulation Association (NIA), in conjunction with its Alliance

partners, worked to design, implement, and execute the Mechanical Insulation

Education & Awareness Campaign (MIC).

The MIC is a program to

increase awareness of the energy efficiency, emission reduction, economic

stimulus potential, and other benefits of mechanical insulation. An integral

component of the MIC was the development of a series of “Simple Calculators.”

The calculators, listed below, provide users with instantaneous information on

a variety of mechanical insulation applications in the industrial/manufacturing

and commercial markets.

- Condensation Control for Horizontal Piping

- Energy Loss, Emission Reduction, Surface Temperature, and Annual Return

for Equipment and Piping - Insulation Financial Returns

- Estimate Time to Freezing for Water in an Insulated Pipe

- Personnel Protection for Horizontal Piping

- Temperature Drop for Air in an Insulated Duct or Fluid in an Insulated

Pipe

The calculators are online as part of the National Institute of Building

Sciences’ Mechanical Insulation Design Guide (MIDG), www.wbdg.org/design/midg_calculators.php. You can also access them through a link on NIA’s

website: www.insulation.org. The calculators are fast, free, and

functional tools that make it easy to discover energy savings, financial

returns, and other information for the design of mechanical insulation systems

for above- or below-ambient applications.

This article provides an

overview and a guide on how to use the Financial Returns Calculator and the

Personnel Protection for Horizontal Piping Calculator.

Insulation Financial Returns Calculator

Insulation systems are frequently designed with the

objective of minimizing costs. Properly designed insulation systems can reduce

heat loss or gain from (or to) mechanical systems by 90 to 98%. Since energy

must be purchased to offset these heat flows, insulation systems can quickly

pay for themselves in reduced energy costs.

Insulation projects, like many

energy-conservation projects, generally involve making an initial investment

that will result in future cost savings. A number of approaches can be used to

measure the financial desirability of an insulation project. All require

estimates of the initial investment (in this case, the installed cost of the

insulation system) and the resulting future savings. Some of these financial

measures are simple, like return on investment (ROI) and simple payback period.

Others are more complicated and take into account the time value of money,

inflation, and taxes.

This calculator was developed

to provide a convenient way to estimate the financial returns related to

investments in mechanical insulation: simple payback in years, internal rate of

return (IRR or ROI), net present value (NPV), and annual and cumulative cash

flow. It can be used for an overall mechanical insulation project or for a

small investment such as insulating a valve or replacing a section of

insulation. Tax implications of the investment have not been considered in the

Financial Calculator. You should consult your financial advisor for specific or

tailored financial calculations. (For further information on the definition of

terms used in the calculator, please refer to the MIDG website.)

The calculator requires input information for five variables. The

“Results” and “Calculations” sections are updated as each input variable is

entered. Here are instructions and additional information for each input

variable. Sample inputs appear in a box, after each instruction.

- Line 1. Enter the cost of installing or replacing insulation, $10000

The default value is $10,000. However, you may

enter any positive dollar amount. You may use the overall cost of a mechanical

insulation project, or a small mechanical insulation investment. - Line 2. Enter the estimated energy

cost savings during the first year, $/yr 5000The default value

is $5,000/yr; however, you should enter the estimated savings for the scope of

work you identified in Line 1. You can use the Energy Calculators for

Horizontal Piping and Equipment within the MIDG Simple Calculator section to

estimate the annual savings. See the March 2013 issue of Insulation Outlook

for instructionson on using the Energy Calculator for Horizontal Piping.- Line 3. Enter the projected

annual energy cost escalation rate, %/yr 3.0Energy cost savings after the first year are assumed to increase at the

energy cost escalation rate. The default value is 3%; however, you should enter

your best estimate of the percentage

that you expect the cost of your energy source to increase by

annually over the life of the scope of work identified in Line 1. - Line 3. Enter the projected

- Line 4. Enter the estimated economic life of the insulation system,

yrs 20The default value

is 20 years; however, you should enter your best estimate as to the expected

useful life for the scope of work identified in Line 1. - Line 5. Enter the discount rate

for NPV calculation, % 5.0

The default value is 5%. NPV is the difference between the present value

of cash inflows and the present value of cash outflows. The input box requires

selection of an appropriate discount rate, sometimes referred to as the “hurdle

rate” or the “required rate of return.” It should be established as equal to

the highest rate of return available on alternative investments of comparable

risk, or a company-established minimum threshold.

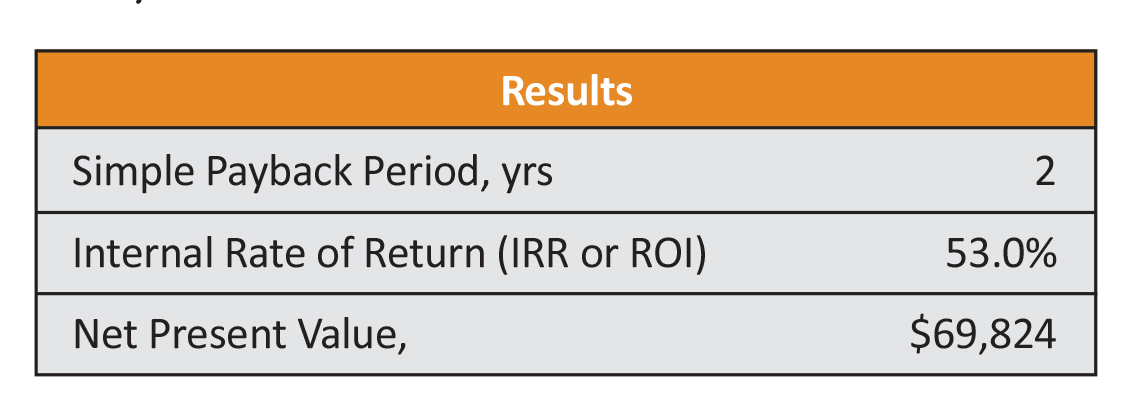

Based on the input information entered, the “Results” section provides

the calculated simple payback period, IRR or ROI, and NPV. An example using the

default values for all input variables is shown below. Note that the simple

payback is calculated as the initial cost divided by the first-year savings.

The calculator assumes that initial investment occurs at the beginning of Year

1, and annual savings occur at year-end. Savings after 20 years are ignored.

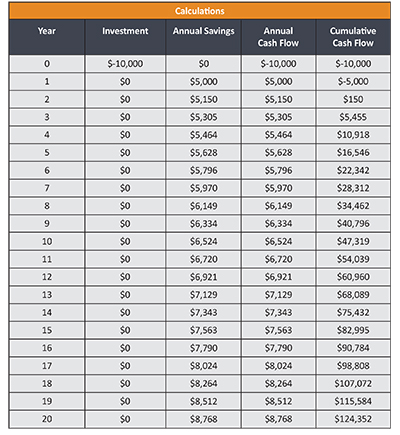

The “Calculations” section, using the default values for all input

variables, is shown below. This section illustrates the initial Investment, the

Annual Savings, Annual Cash Flow, and Cumulative Cash Flow over the economic

life of the application. Using the default value examples, a $10,000 initial

investment yielding $5,000 of first-year savings will yield $124,352 net of the

initial investment—before discounting—at the end of 20 years. The NPV of this

investment is $69,824.

Personnel Protection Calculator for Horizontal

Piping

As described on the MIDG—Simple Calculators web

page, this calculator estimates the maximum contact exposure time on the outer

surface of a horizontal pipe insulation system based on the potential for

contact burn injuries. Input requirements include the pipe size, operating

temperature, ambient temperature, wind speed, and details about the insulation

system (material and jacketing).

The maximum contact exposure

times are estimated using the procedures outlined in ASTM C 1055-03 (Reapproved

2009) Standard Guide for Heated System Surface Conditions that Produce Contact

Burn Injuries. This guide establishes a means by which the engineer, designer,

or operator can determine the acceptable surface temperature of a system where

contact may be made with a heated surface.

For the purposes of this calculator, the maximum contact exposure times

are based on an acceptable injury level of first degree burns (reversible

epidermal injury, or the limit represented by the lower “Threshold B” curve

shown in Figure 1 of the Standard). Acceptable contact times will depend

on the application. The Standard recommends, based on a survey of the medical

literature, 5 seconds for industrial processes and 60 seconds for consumer

items.

The insulation materials

included in this calculator were selected to be representative of some of the

materials commonly used in the industry. The list is not inclusive of all

materials types and other materials are available. The calculator does not

screen for material temperature limitations, so use caution when selecting the

materials.

For further information on the

thermal conductivity data used in the calculator, please refer to the MIDG

Personnel Protection Calculator for Horizontal Piping. Also note that some

materials are not available in all of the sizes and thicknesses covered, and

some are available in sizes and thicknesses not listed.

The calculator requires input

information for 6 variables. The “Results” section is updated as each input

variable is entered. Following are the instructions and additional information

for each input variable.

- Line 1. Select Nominal Pipe Size NPS 4

The default value is an NPS of 4″; however, you

can select any pipe size from ½” to 24″ from the drop down box. - Line 2. Enter operating (process) temperature, °F 800

The default value

is 800°F. You should enter the actual operating or process temperature. - Line 3. Enter average temperature of the air surrounding the pipe, °F

75The default value

is 75°F; however, you should enter the average surrounding or ambient operating

temperature, in Fahrenheit, for the area in question. - Line 4. Enter the wind speed of the ambient air (if unknown, use 0

mph for worst-case conditions) 10The default value

is 10 mph. However, when in doubt, use 0 mph, which represents the worst-case

conditions. - Line 5. Select an insulation material Mineral Wool (to 1200°F)

The default box

indicates Mineral Wool; however, you may select one of eight insulation

materials from the drop-down box: Calcium Silicate, Cellular Glass,

Elastomeric, Fiberglass, Mineral Wool, Polyethylene, Polyisocyanurate, or

Polystyrene. - Line 6. Select the effective emittance of the exterior surface

0.80 – Painted MetalThe default box

indicates painted metal; however, you may use the drop-down menu to select one

of twelve exterior surfaces. For a detailed discussion and definition of

emittance, please refer to the MIDG website.

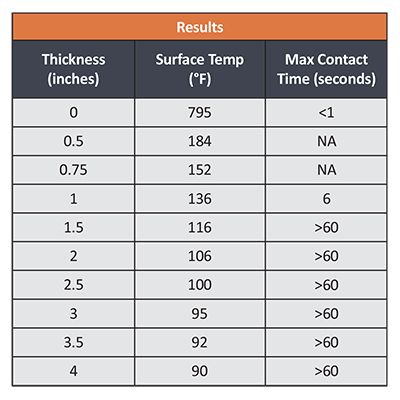

The “Results” section, using

the default values for all input variables, is shown below. The section

illustrates, for a range of thicknesses of the insulation material selected,

the calculated surface temperature and resulting maximum contact time in

seconds.

Note that the Personnel Protection Calculator incorporates a number of

important simplifying assumptions. Refer to the MIDG web page for further

discussion of these assumptions.

Summary

While they do not address every insulation material

or application condition (thus the term, Simple Calculators), the Simple

Calculators are intended to provide the user with online, easily accessible,

snapshot information on some of the most frequently asked-about benefits and

design considerations of mechanical insulation systems.

Whether you need basic

insulation information or are designing a complex insulation system, MIDG (www.wbdg.org/design/midg_introduction.php)

is a tremendous resource for the novice or the experienced user. Along with the

calculators, it contains everything you need to know about the design,

selection, specification, installation, and maintenance of mechanical

insulation. MIDG is continually updated with the most current and complete

information, including the Simple Calculators. These tools can be very helpful

in designing a mechanical insulation system and they allow the user to easily

determine the many benefits and value of mechanical insulation.