Metal Building Insulation and Air Leakage

Architects, engineers, and specifiers are required to incorporate energy efficiency codes as they continue to change with each passing cycle. One aspect strongly reflected in the approved energy codes is the tested air leakage requirements for structures, including metal building systems. A couple of states are early adopters (California and Washington), but many states—particularly those who have adopted ASHRAE 90.1-2019 and International Energy Conservation Code (IECC) 2021—will need to get ready. Now.

In this article, we will focus on air leakage reduction, which goes back to the 2012 IECC, and how fiberglass insulation systems meet all current requirements. The air leakage provisions were developed in response to the diminishing returns of adding more mass fiberglass insulation in cavity spaces and environmental pressures from various agencies.

In 2012, the IECC introduced an air leakage component and provided three paths to compliance, each governed by a respective ASTM standard and measured at a pressure differential of 75 Pascals (1.57psf). Below are the three compliance options.

- Materials with an air permeability no greater than 0.004 cfm/ft2

- Assemblies of materials and components not to exceed 0.04 cfm/ft2

- Whole building air leakage test results not to exceed 0.40 cfm/ft2

In simple terms, air leakage tests incorporate a blower door, visual inspection, and infrared pictures. In a commercial building, the test involves sealing the building, using a fan (or fans, depending on building size) to create pressure differences, and measuring air flow to detect leaks. Data from pressure differentials, visual inspections, and infrared technology identify those air leak points, now mandatory for any state adopting IECC 2021 or ASHRAE 90.1 2019.

It is important to note a key difference between IECC and ASHRAE 90.1: The IECC requires a whole building test, unless an exemption applies due to climate zone or building size; whereas ASHRAE 90.1 allows the use of an installation verification program instead of a whole building test for any building.

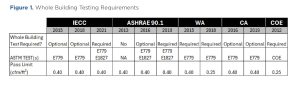

Figure 1 shows the progression of whole building testing requirements (ASTM E779).

Many members of NIA’s Metal Building Laminator Committee are also members of the Metal Building Manufacturers Association (MBMA) and its Air Leakage Task Force. This group, with the help of third-party experts, led air leakage tests on several newly constructed metal building systems to evaluate air leakage. These studies encompassed various climate zones, building uses, and fiberglass insulation systems. It was important to test how fiberglass insulation systems perform and ensure these products would meet the air leakage requirements.

After many tests, it was concluded that all the tested fiberglass insulation systems yielded a positive result concerning the 0.40 cfm/ft² threshold. The project highlighted the importance of and level of detail needed for the installation technique used for all materials. The studies culminated in the MBMA publication of “Best Practices to Comply with Whole Building Air Leakage Testing Requirements for Metal Building Systems.”

Many states (13) have already adopted IECC 2021/ASHRAE 90.1–2019, and it is just a matter of time before other states follow. As communicated in this article, anything after the 2012 IECC will have an air infiltration component to it. Now is the time to prepare and understand what may be required.

As members of NIA’s Metal Building Laminators Committee and suppliers of fiberglass insulation systems, we are attuned to and participate in energy efficiency and building code developments. Please reach out to us if you have questions or need to understand how air infiltration will affect your project.

The following are additional resources:

- Metal Building Manufacturers Association: MBMA_Best_Practices_to_Comply_with_Whole-Building_Air_Leakage_Testing_Requirements_for_MBS_061223.pdf

(https://tinyurl.com/yxwv7asv) - Air Barrier Association of America: www.airbarrier.org/technical-information/

whole-building-air-tightness-testing-2/ (https://tinyurl.com/5f5e2jvy) - ASHRAE: 90.1-2019_ENVELOPE_Final.pptx (live.com) (https://tinyurl.com/5ep2nkrc)