Mitigating Corrosion under Insulation while Reducing Carbon Emissions—A Winning Combination

This article was written before King passed away, and it originally appeared in the June 2025 issue of Materials Performance, a publication of the Association for Materials Protection and Performance (AMPP).

As reported in Insulation Outlook, NIA and AMPP are working together on establishing a mechanical insulation standards program. This collaboration is a step forward in our mutual commitment to sustainability, energy efficiency, safety, decarbonization, and enhancing the value insulation brings to the global market. Together, we are setting a new benchmark for quality and performance, ensuring that our industries not only meet but exceed the expectations of today and the demands of tomorrow. To read the latest on the standards development, see “Bridging the Gaps: New AMPP/NIA Mechanical Insulation Standards Aim for Industry-Wide Solutions” on page 35.

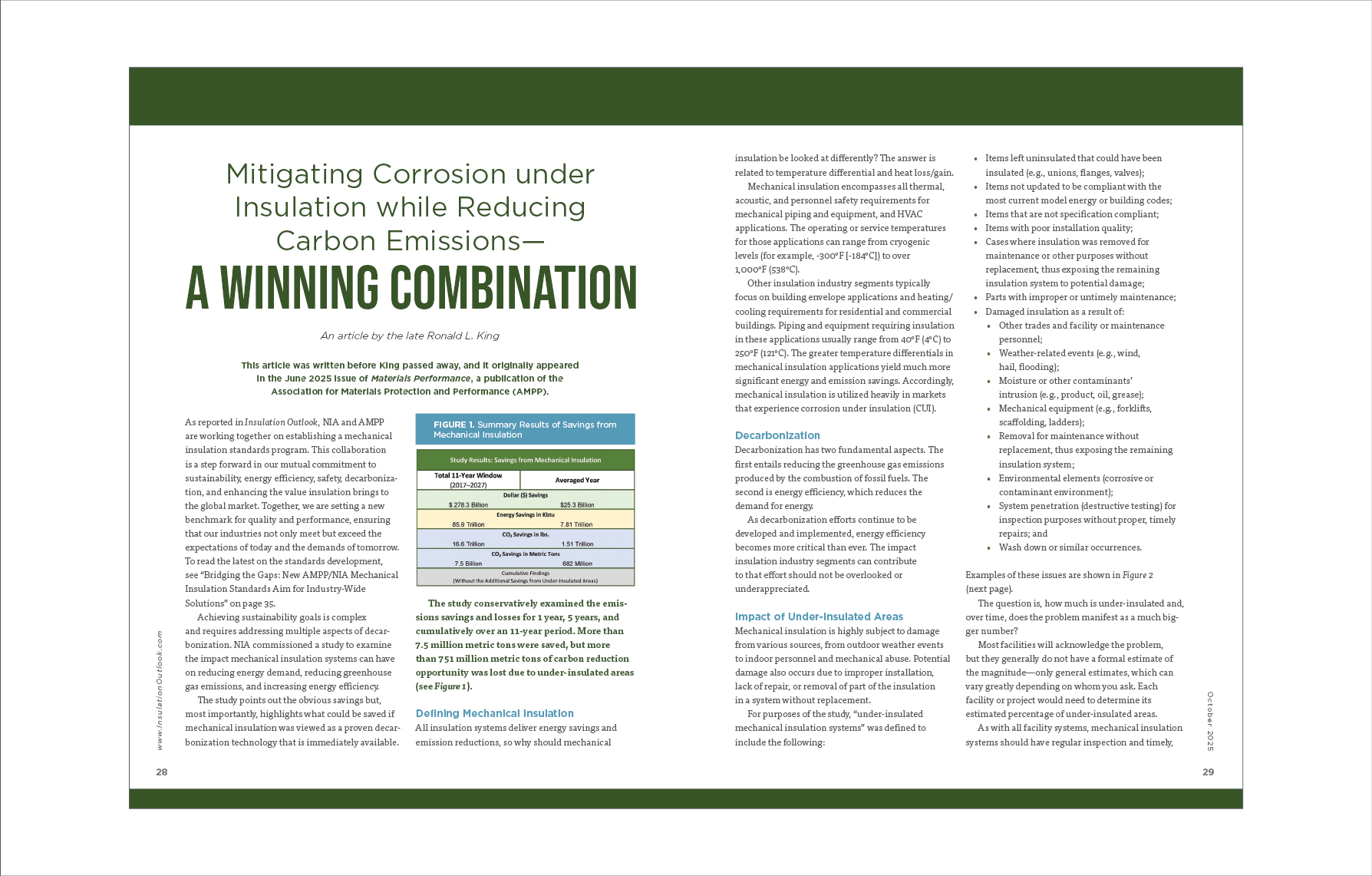

Achieving sustainability goals is complex and requires addressing multiple aspects of decarbonization. NIA commissioned a study to examine the impact mechanical insulation systems can have on reducing energy demand, reducing greenhouse gas emissions, and increasing energy efficiency.

The study points out the obvious savings but, most importantly, highlights what could be saved if mechanical insulation was viewed as a proven decarbonization technology that is immediately available.

The study conservatively examined the emissions savings and losses for 1 year, 5 years, and cumulatively over an 11-year period. More than 7.5 million metric tons were saved, but more than 751 million metric tons of carbon reduction opportunity was lost due to under-insulated areas (see Figure 1).

Defining Mechanical Insulation

All insulation systems deliver energy savings and emission reductions, so why should mechanical insulation be looked at differently? The answer is related to temperature differential and heat loss/gain.

Mechanical insulation encompasses all thermal, acoustic, and personnel safety requirements for mechanical piping and equipment, and HVAC applications. The operating or service temperatures for those applications can range from cryogenic levels (for example, -300°F [-184°C]) to over 1,000°F (538°C).

Other insulation industry segments typically focus on building envelope applications and heating/cooling requirements for residential and commercial buildings. Piping and equipment requiring insulation in these applications usually range from 40°F (4°C) to 250°F (121°C). The greater temperature differentials in mechanical insulation applications yield much more significant energy and emission savings. Accordingly, mechanical insulation is utilized heavily in markets that experience corrosion under insulation (CUI).

Decarbonization

Decarbonization has two fundamental aspects. The first entails reducing the greenhouse gas emissions produced by the combustion of fossil fuels. The second is energy efficiency, which reduces the demand for energy.

As decarbonization efforts continue to be developed and implemented, energy efficiency becomes more critical than ever. The impact insulation industry segments can contribute to that effort should not be overlooked or underappreciated.

Impact of Under-Insulated Areas

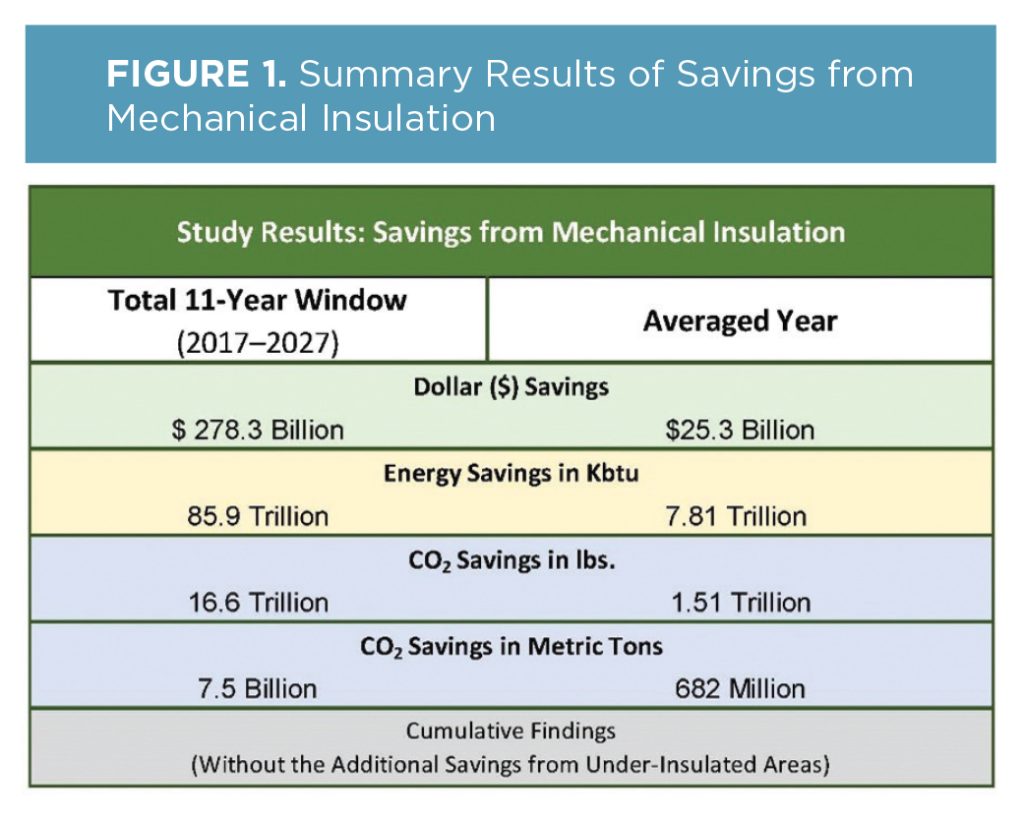

Mechanical insulation is highly subject to damage from various sources, from outdoor weather events to indoor personnel and mechanical abuse. Potential damage also occurs due to improper installation, lack of repair, or removal of part of the insulation in a system without replacement.

For purposes of the study, “under-insulated mechanical insulation systems” was defined to include the following:

- Items left uninsulated that could have been insulated (e.g., unions, flanges, valves);

- Items not updated to be compliant with the most current model energy or building codes;

- Items that are not specification compliant;

- Items with poor installation quality;

- Cases where insulation was removed for maintenance or other purposes without replacement, thus exposing the remaining insulation system to potential damage;

- Parts with improper or untimely maintenance;

- Damaged insulation as a result of:

- Other trades and facility or maintenance personnel;

- Weather-related events (e.g., wind, hail, flooding);

- Moisture or other contaminants’ intrusion (e.g., product, oil, grease);

- Mechanical equipment (e.g., forklifts, scaffolding, ladders);

- Removal for maintenance without replacement, thus exposing the remaining insulation system;

- Environmental elements (corrosive or contaminant environment);

- System penetration (destructive testing) for inspection purposes without proper, timely repairs; and

- Wash down or similar occurrences.

Examples of these issues are shown in Figure 2.

The question is, how much is under-insulated and, over time, does the problem manifest as a much bigger number?

Most facilities will acknowledge the problem, but they generally do not have a formal estimate of the magnitude—only general estimates, which can vary greatly depending on whom you ask. Each facility or project would need to determine its estimated percentage of under-insulated areas.

As with all facility systems, mechanical insulation systems should have regular inspection and timely, proper maintenance or the problem will become worse. What today may be a simple repair could be a major problem tomorrow. Additionally, other potential consequences, such as personnel and process safety concerns, process control, and CUI, need to be considered.

Industrial Versus Commercial Market Segment

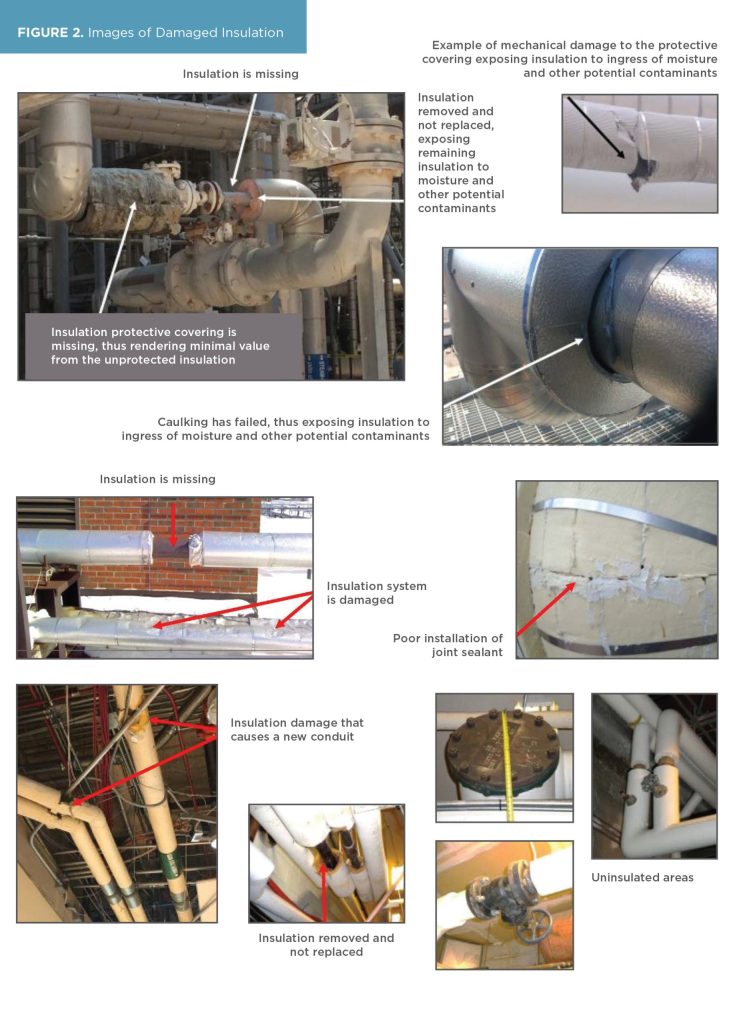

The industrial segment represents a larger percentage of under-insulated areas than the commercial segment. Many of the insulated piping systems in the commercial segment are located in wall cavities or above ceilings and, accordingly, are not exposed to weather elements or potential mechanical or personnel abuse on a regular basis.

Because the breakdown between market segments is unknown, through a series of estimates, assumptions, and extrapolations, the total savings was allotted between the two market segments. On average, based on the variable percentages of under-insulated areas, the potential loss equates to 10%. For the commercial market, 1.7% was allocated, and for the industrial market segment, it was 8.3%, or an approximate ratio of 1 to 5. More than 751 million metric tons of carbon reduction opportunity was lost due to under-insulated areas (see Figure 3).

Recognizing that mechanical insulation is highly subject to damage from various sources provides the bridge to the discussion of mitigating CUI.

Corrosion Under Insulation

One of the most common concerns about mechanical insulation systems is the risk of CUI. The 2013 NACE Impact Study estimated the cost of CUI in the U.S. industrial market segment alone above $300 billion. On a global scale, across all economic sectors, the cost of CUI was estimated at more than $2.5 trillion in 2013.

It is important to understand that insulation does not cause corrosion. CUI is an electrochemical process. For CUI to start and continue, a combination of the following conditions must be present:

- Oxygen,

- Corrosive chemicals or compounds – pH < 7,

- A temperature at the metal surface between 50°F and 350°F (or a cyclic system that passes through this range at regular frequency), and

- An electrolyte (liquid water) to “close” the anode/cathode pathway.

Most industry experts agree that the primary cause of CUI is moisture/water ingress into the insulation system that migrates to the exposed metal surface beneath. Those same experts also believe that moisture/water will eventually get into the metal/insulation interface.

How does water get into a mechanical insulation system? Look back at the list of under-insulated areas and consider the following:

- Mother Nature—rainwater, including flooding conditions;

- Surrounding environment—cooling towers, as an example;

- Condensation development—on or in the insulation system;

- Sprinkler and/or fire control efforts;

- Wash water and/or deluge system water; and

- Pipe or equipment leakage.

To mitigate CUI, you have to keep the moisture out or get it out. You also have to think about mechanical insulation as a system, starting with a coating of the substrate and the design and selection of all materials within the insulation system, ensuring the initial installation is correct and followed by timely and proper maintenance.

We look back at the degree of potential conflicting specifications, lack of accepted application standards, improper installations, and the amount of under-insulated areas, and we ask why or how this happened. That answer comes to a few basic topics for most applications.

- Understanding and appreciating that mechanical insulation systems require continual inspection and maintenance.

- Capital cost is the primary focus of new construction, often at the expense of future operational and maintenance cost considerations.

- The consequences of improper installation and maintenance is only fully appreciated once problems occur.

- The investment aspect (financial and emission return on investment components) of maintaining an insulation system is not considered, potentially creating barriers to change.

- Hurdles are continuously created by conflicting business and decarbonization/sustainability objectives.

- Lack of knowledge and education about all aspects of mechanical insulation systems.

The solutions are complex; there are many opinions as to the best paths to follow, and effective change will take time. But the one change that can happen immediately is to view mechanical insulation as a proven technology and investment that will help achieve a company’s and our country’s decarbonization and sustainability objectives while taking a big step in mitigating CUI.

The challenge for business, finance, and policymakers is identifying how best to use the time and resources—and, especially, solutions—that are available now to advance the changes needed.

Next Steps

While each business or company may have unique circumstances, structures, and procedures to consider, a few common next steps should be considered in determining how and to what level mechanical insulation can help achieve the respective decarbonization goals while helping mitigate CUI.

- Commit to investigating and developing a better understanding of the benefits of mechanical insulation and the consequences of not having up-to-date specifications, improper installation, or insufficient or improper maintenance.

- Complete a thorough and objective review of current project or company specifications or standards and develop recommended changes, if any.

- Develop and implement specific mechanical insulation energy efficiency and emission reduction appraisals/audits and assessments of existing mechanical insulation with inspectors and appraisers certified in those fields.

- Determine the internal and external hurdles or barriers to implementing mechanical insulation energy and carbon reduction initiatives.

- “Inspect what you expect”—not only in monitoring and recording progress of specific plans, but during the initial installation and maintenance processes.

- Develop an annual inspection and maintenance program for existing facilities. This will benefit short- and long-term operational and capital budget planning, and the information could be used in internal and external climate change/sustainability programs, and to mitigate CUI.

- Ensure you have transition plans to transfer the mechanical insulation expertise and technology to your personnel. So often, knowledge is lost by right-sizing, downsizing, attrition, changes in responsibility, change of ownership, or mergers.

The technology known as mechanical insulation is available now, and it impacts every state, county (province), city, labor group, direct or indirect related business, and this and future generations.

That is potentially the industry’s greatest challenge. It is hoped that articles like this can be the nucleus of impacting change.