NIA Contractor Member Performance Contracting, Inc. Discusses System Design

NIA is proud of the professionalism, creativity, and artistry of our Contractor members. To celebrate the craftsmanship of NIA mechanical and industrial insulation contractors, NIA established the Insulation Project Art Gallery Showcase and Competition in 2023. Last year, we again invited all NIA insulation contractors to submit photographs and a brief description of projects representing their most creative and artistic efforts. At our Fall Summit, we posted all the submissions anonymously, and attendees voted for the top three projects in terms of number of parts insulated, aesthetics, difficulty of installation, and well-installed application. We will profile the projects submitted, focusing this month on second-place (tie) winner Performance Contracting, Inc. (PCI). We encourage NIA Contractor members to participate in this year’s competition and possibly be featured in a future article. After this year’s competition, the next chance to compete will be in 2027, as the Contractor Showcase moves to a biennial schedule.

Project Description and Goals

This project involved the renovation of an existing data center in Birmingham, Alabama, which was built in the early 2000s. The project focused on upgrading the cooling and emergency power systems, which included the replacement of 8 chillers, 8 cooling towers, 24 chilled-water pumps, 10 emergency generators, and several computer room air conditioning (known as CRAC) units.

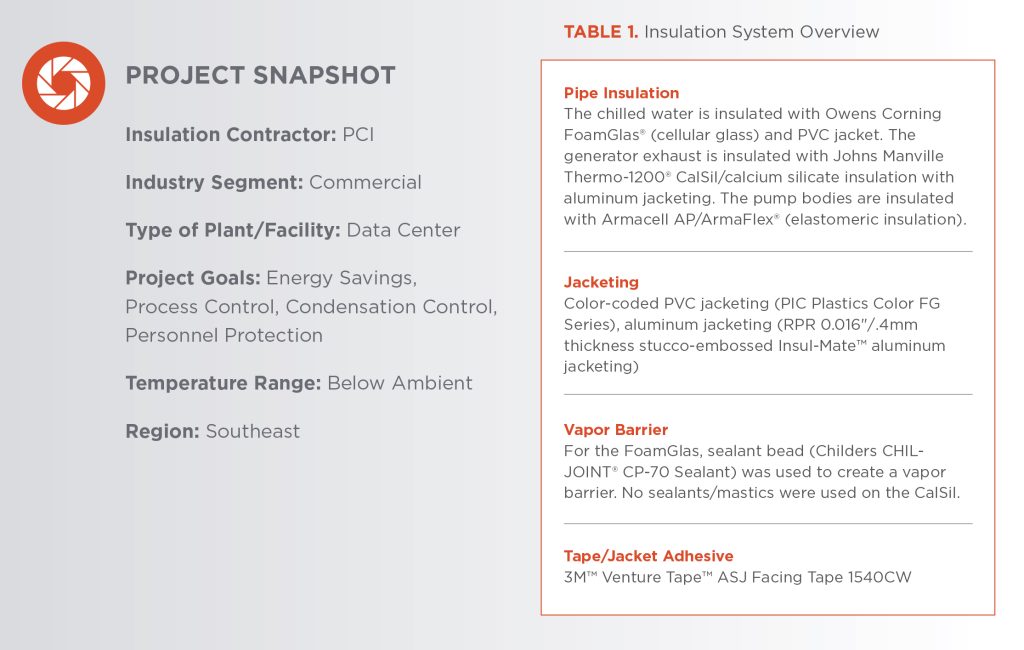

The enhancements aimed to improve the efficiency and reliability of the data center’s infrastructure, ensuring optimal performance and minimizing downtime. The project also included the implementation of advanced monitoring and control systems to provide real time data on the performance of the new equipment. This comprehensive upgrade not only enhanced the data center’s operational capabilities, but it also will contribute to ongoing energy savings and reduced environmental impact. For details about the insulation system products used, see Table 1.

Challenges

Access and scheduling were two large challenges for this 2-year renovation project. Regarding access, because this jobsite was an active data center for a bank, everyone who visited the site underwent a background check, which took time. To meet the tightly controlled schedule, the PCI team focused on planning and coordination to avoid delays, with attention to scheduled freeze periods that coincided with high banking transaction activity, such as the end of the month and around holidays, as well as unscheduled periods when the facility deemed it necessary to close access to the jobsite.

In addition, the mechanical systems could only be shut down for limited amounts of time due to the facility’s operations, so the PCI team had strict timelines. According to PCI Project Manager/Estimator Jene Johnson, “We had a certain amount of time to get our scope done, as our customer had to continue operations. We were informed when the systems needed to come back online, and we had to be done. Not completing the scope within the schedule was not an option.”

Project Takeaways

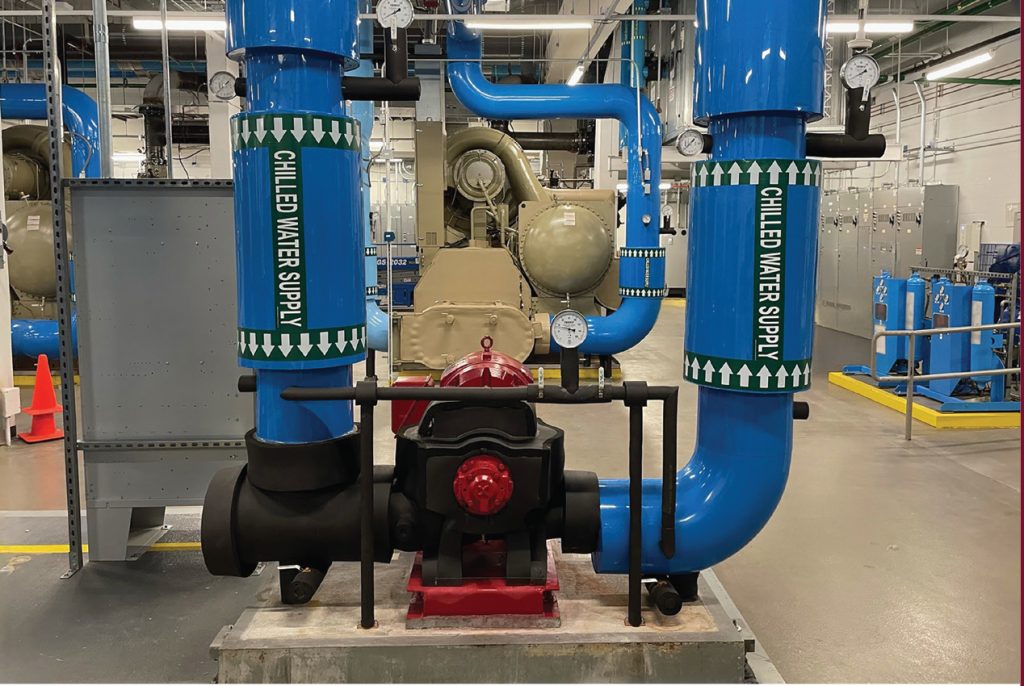

Assemble a Great Team for a Project that Will Shine

Johnson shared, “On many of our projects, a majority of our work is above ceilings and behind walls, and you never see it. For this project, with the two large mechanical rooms and all the colored PVC jacketing, this was truly a showcase project. We wanted to make these mechanical rooms shine. Our customers, engineers, and facilities personnel are in and out of these rooms, and they can see the craftsmanship of this custom work. Our guys knocked it out of the park, and I was incredibly proud of our work on this project. Our customers were pleased, giving us a few pats on the back and some ‘atta-boys,’ especially when it came to our care in matching the PVC colors.” He added, “The color PVC not only looks pristine, but it will also help the facility’s engineering teams during future maintenance work with identifying supply and return lines.” (See Photos 1 and 2.) The removable insulation pads designed in-house by PCI for the Y-shaped exhaust ports on the backup generators will also allow for maintenance access. (See Photos 3 and 4.)

Remain True to Your Core Values

Safety is PCI’s number one core value. Johnson noted that the PCI team had all the equipment, lifts, scaffolding, and anything else they needed to complete the project. The team had no safety incidents during this 2-year project.

Meet Tough Challenges Head on

When looking back on this project, Johnson noted, “You can always learn something from every single project you complete, and even the most complicated projects are within our abilities. The scheduling intricacies were huge with this project. We had a great customer, a dedicated team, and we delivered a beautifully functioning project all while dealing with the complicated intricacies of working in an existing data center. The system was expertly designed and installed, and works flawlessly.”

PCI recognizes the team members who played a vital role in this project.

- Jene Johnson, Estimator/Project Manager

- Randy Watson, Superintendent

- Steve Cagle, Foreman

- Charlie Hereford, Project Engineer

About PCI

As a top-tier specialty contractor in the United States, PCI delivers exceptional services and products to industrial, commercial, and nonresidential sectors. Offering a wide range of related services, PCI has established itself as a true “one-stop-shop” contractor, ensuring its customers receive comprehensive solutions tailored to their specific needs. Headquartered in Lenexa, Kansas, PCI is an employee-owned company with a nationwide network of more than 40 offices. For more information, visit www.performancecontracting.com.