NIA Contractor Members Discuss System Design: Elite Insulation

Featuring the Participants of the Inaugural Insulation Project Art Gallery Showcase and Competition

NIA is proud of the professionalism, creativity, and artistry of our Contractor members. To celebrate the craftsmanship of NIA mechanical and industrial insulation contractors, in 2023 we unveiled the first-ever NIA Insulation Project Art Gallery Showcase and Competition. We invited all NIA insulation contractors to submit photographs and a brief description of projects representing their most creative and artistic efforts. At Fall Summit, we posted all the submissions anonymously, and attendees voted for the top three projects in terms of number of parts insulated, aesthetics, difficulty of installation, and well-installed application. As a new regular column, we will profile these knowledgeable contractors and learn how each submitted project was designed, beginning this month with the 1st Place winner: Elite Insulation, Inc. We encourage NIA Contractor members to participate in the 2024 Insulation Project Art Gallery Showcase and Competition, and possibly be featured in future articles.

PROJECT SNAPSHOT

- Insulation Contractor: Elite Insulation, Inc.

- Industry Segment: Food Processing

- Type of Plant/Facility: Brewery

- Temperature Range: Below Ambient

- Region: Midwest

- Location: Indoors and Outdoors

- System Designed/Application Type: Chilled Water

Project Description and Goals

A brewery in the Midwest was looking to complete a major expansion, which involved both indoor and outdoor new construction and insulation installation. The customer’s goals were to achieve energy savings and maximize system performance and longevity in a high humidity/high-moisture environment, while also building in flexibility for future expansion at the site.

Challenges

The first challenge was the point when Elite was brought into the project. Construction was already well underway when they were asked to conduct an inspection of existing conditions and provide an approach and estimate for the way ahead. When Elite owner and founder Brooks Holmgren walked the site, “I was really shocked at how large the expansion was.” He also saw why it was critical that a knowledgeable insulation contractor be involved. The catwalks and a lot of expensive equipment, from the 1,200 can per minute canning machine to the massive tunnel pasteurizer, were already installed. This required Elite professionals to operate the boom and scissor lifts very carefully to avoid damage to any of the sensitive equipment. Having previous experience with the unique environment in a brewery, and the additional considerations for health and safety in all food processing facilities, helped guide Elite’s solution.

Finally, starting work weeks before the Christmas and New Year’s holidays, with the customer desiring everything to be fully operational as soon as possible, translated to long hours and no small amount of stress. Inside, Holmgren knew once testing/production started, they would run the risk of condensation, so the interior insulation work was priority. Once that was completed (right before Christmas), they moved outside, where the cold Wisconsin winter actually worked in their favor: The pipes were too cold for condensation to form.

Elite’s Solution

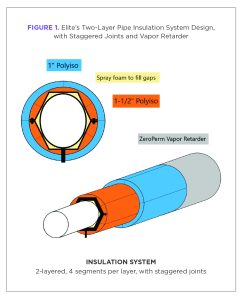

The performance goals for the insulation system were to achieve the best R-value possible for a below-ambient system, provide high-density protection, and resist condensation and moisture intrusion. As shown in Figure 1, Elite’s pipe insulation approach was a two-layer, half round shiplap, with staggered joints and a vapor retarder. Joints were staggered to reduce potential for thermal bridging and moisture intrusion. Holmgren explains, “With any insulation, over time, if compromised the insulation joints will start to separate, allowing for condensation and moisture intrusion. With an overlap joint, moisture intrusion does not have a direct, straight path. Even if the first layer shrinks, you still have that R-value coverage.”

Elbows were either polyiso/styro (two piece), or two-layer/two-piece elastomeric/rubber, necessitated by the size of the equipment and the tight position where they were installed. This approach also reduced the amount of seams and cut joints, and provided a vapor retarder. Again, seams were staggered.

Elastomeric was used on flanges and valves to accommodate the customer’s plans for future expansion and ease of maintenance. Holmgren explains, “There’s so much wet work with a brewery, cleaning and washing stuff down. If they get wet, joints and seals are the perfect place for mold to grow… You need something to be fully sealed, with no open seams, 100% glued, not just taped so it can hold up to hot high-pressure washing.”

The same approach was used for the outside components, but Elite used stucco aluminum metal jacketing instead of PVC for protection against the elements and UV damage. Additionally, stainless banding was used instead of screws so as not to puncture the vapor retarder. Both inside and outside, on the fittings that were bigger than stamped two-piece fittings, gored segments were field fabricated and installed.

Elite had recently purchased a CNC cutting machine. Holmgren explained it “cuts polyisocyanurate, styrofoam, cellular glass, and mineral wool. Behind the scenes, we’d been trying to get this machine set up so we can make our own pipe covering… [The] machine allows you to select thickness, size, segments, and all that. It was a mad dash to get that set up to use it for this and ship it out.” This allowed them to “really customize a job, regardless of shape.” Holmgren was able to get “all the buns and spent endless hours getting it done in time.”

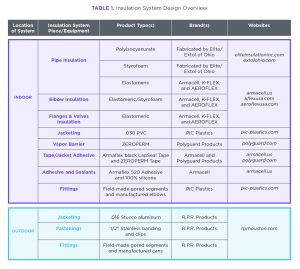

Table 1 offers an overview of insulation system components, as well as product types and brands used.

The “Wow Factor”

The use of two colors for the interior PVC jacketing has a practical benefit: It makes it easy for the customer’s employees to identify and follow the supply and return lines in the maze of pipes. Holmgren says once the customer understood the utility of the two-tone approach—and learned there would be no change in cost to use color—it only made sense to use the brewery’s colors. Their original logo was purple, which has transitioned to blue, so those are the colors you see in the photos. The “wow factor” is further amped up by the artwork, which brings the brewery’s Octopi logo to life. To carry the look outside, Holmgren hand-rolled the logo into a metal endcap.

The creativity not only won Elite 1st place in NIA’s competition, but it won over the customer. Holmgren says, “The cool thing is, after doing the project… the owner noticed every little detail, which was refreshing.” He adds that there was another, intangible benefit he saw during installation: “When we did the purple beer line, it brightened people’s day. Doing color makes people happier.”

Project Takeaways

This project is not only visually striking, but it also offers lessons in several key areas.

Design. The project is a case study in why insulation contractors should be consulted early in the design process. “If you’re going to do a project in the future, before you get too far into it, bring insulation contractors in and involve us so we can educate you on what type of hangers to use, for example, to leave enough space,” Holmgren says, adding that mechanical insulation contractors’ expertise and input can save customers both time and money. Even a simple observation that pipe and ducts could be run a shorter, more direct, way can reduce the amount of footage needing insulation—and, therefore, project cost. And because Holmgren knows the main areas to troubleshoot, for example, where condensation or leaks are most likely to occur, getting his input in the design phase can result in selecting an approach and materials that will require less maintenance over time. “Elite’s [goal] is to make it work efficiently and have longevity of lifespan for the customer, so they avoid issues down the road. Elite’s main focus is not to come back and repair it year after year.” Finally, bringing in the insulation contractor late in the schedule makes additional, unexpected work or change orders more likely, as elements not originally scoped need to be insulated to achieve the customer’s goals.

The Value of Branding. This project underscores the value for contractors in showcasing not only their skills and commitment to quality workmanship and safety, but also their creativity and artistry—even beyond entering NIA’s competition. Elite got the initial referral because someone from another trade on the job had seen pictures Holmgren posted of another brewery project the company completed. “We get a lot of new work from pictures we put on LinkedIn,” Holmgren says. “Most people just look at insulation and keep walking by. We want the aesthetics and appearance to get attention,” and social media is a great way to expand that reach beyond people who physically visit the site. Holmgren notes that as people see that insulation can be physically attractive, in addition to all its other benefits, “Now, more people want something cool and more visible.” The use of color makes the space more appealing to brewery patrons, and since the brewery’s lines run by the windows, even people driving by can see the colors. Adding the logo allows the insulation to promote the brewery’s brand, even as it delivers performance.

Industry Growth. Holmgren says it is up to contractors to help move the industry forward and explain the difference a creative design and quality installation can make. “If you don’t share it, no one’s going to grow… We need to be licensed installers, certified, and have inspections where we’re held accountable for what we’re installing, just like the plumbing and electrical trades. People’s health can be at risk when working 8–12 hours a day if there is mold.” As the industry faces a continuing labor shortage, Holmgren observes that education, training, good pay, hygienic bathrooms, and “cool projects” can make insulation work attractive to people entering the workforce. “This industry has its opportunities to be artistic and creative when doing projects, so it is interesting. There’s always something new.”

About Elite Insulation, Inc.

Brooks Holmgren founded Elite as a company focused on commercial and industrial customers in February 2002. Since then, the company has grown, completing new construction and renovations on schools and university buildings, restaurants, hospitals, retail stores, government buildings, breweries, water/wastewater facilities, hotels, and more. You can learn more by visiting Elite’s website (https://www.eliteinsulationinc.com/wp/) or contacting Brooks directly (brooks@eliteinsulationinc.com).