NIA Member Fit Tight Covers Discusses System Design

Project Snapshot

NIA Member Company: Fit Tight Covers (FTC)

Industry Segment: Industrial

Type of Plant/Facility: Renewable Natural Gas Facility

Temperature Range: High-Temperature System

Region: Midwest

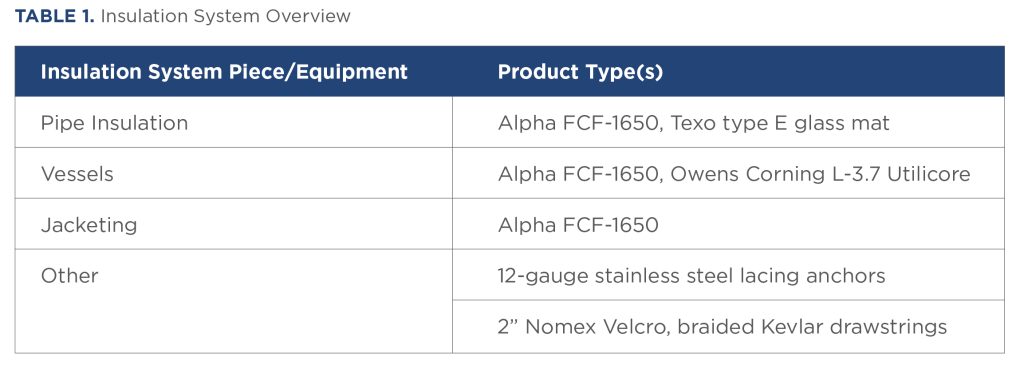

Insulation Materials: Piping – Alpha FCF-1650, Texo Type E Glass Mat Vessels – Owens Corning L-3.7 Utilicore

Jacketing: Alpha FCF-1650

Other: 12-gauge stainless steel lacing anchors, 2” Nomex Velcro, Braided Kevlar Drawstrings

Project Description and Goals

This new construction project was completed at a renewable natural gas landfill site in the Midwest. Capture and processing of natural gas is a growing sector in sustainable energy, and this project is one of more than a dozen sites FTC’s customer is bringing online across the United States.

The facility owner/operator, who also served as the construction manager, had both short- and long-term goals for the project. For the construction phase, the goals were to get the facility up and running as quickly and efficiently as possible, with a solution that would meet the long-term goals as well. Those long-term, post-construction goals included energy savings, process control, and personnel protection/safety.

Challenges

One challenge of working on a project within an ongoing, larger rollout of multiple facilities is that any difficulties encountered on an early job like this one could have a negative ripple effect on other sites as well. For example, failure to meet the aggressive schedule on this project, or being slow to adapt to last-minute design changes, had the potential to disrupt the customer’s construction and operations schedule on a much larger scale, as FTC was responsible for fabrication and hiring the contractors to install the insulation systems on all the sites.

FTC Vice President and General Manager Calvin Brasel explained how the company met this challenge: “We were able to measure, design, and fabricate a solution to help the customer get their plants online faster [including this one]. By using CAD [computer-aided design] and automated cutting tables, we were able to reproduce each part exactly. In the process, we reduced any errors or repairs that would have delayed construction.” Being able to prefabricate the covers for vessels and piping enabled FTC to shorten the project’s duration—not a common occurrence on new construction efforts, and certainly a boost for the customer.

The next challenge came from Mother Nature, as weather threw the project team something of a curve: brutal winter temperatures caused the design team to refine how much of the equipment (instrumentation in particular) needed to be insulated. FTC worked up a modified “winterization” package to accommodate the harsh conditions and kept the project on track.

Perhaps the greatest challenge resulted from the nature of starting up a new facility like this. The customer sought to begin operations as soon as possible, with all the insulation installed to achieve the energy savings and process control—not to mention personnel safety—beginning Day 1. At the same time, facility personnel would need direct access to much of the equipment during the startup phase, when bolts on piping items required retorquing and systems would be adjusted to optimize performance.

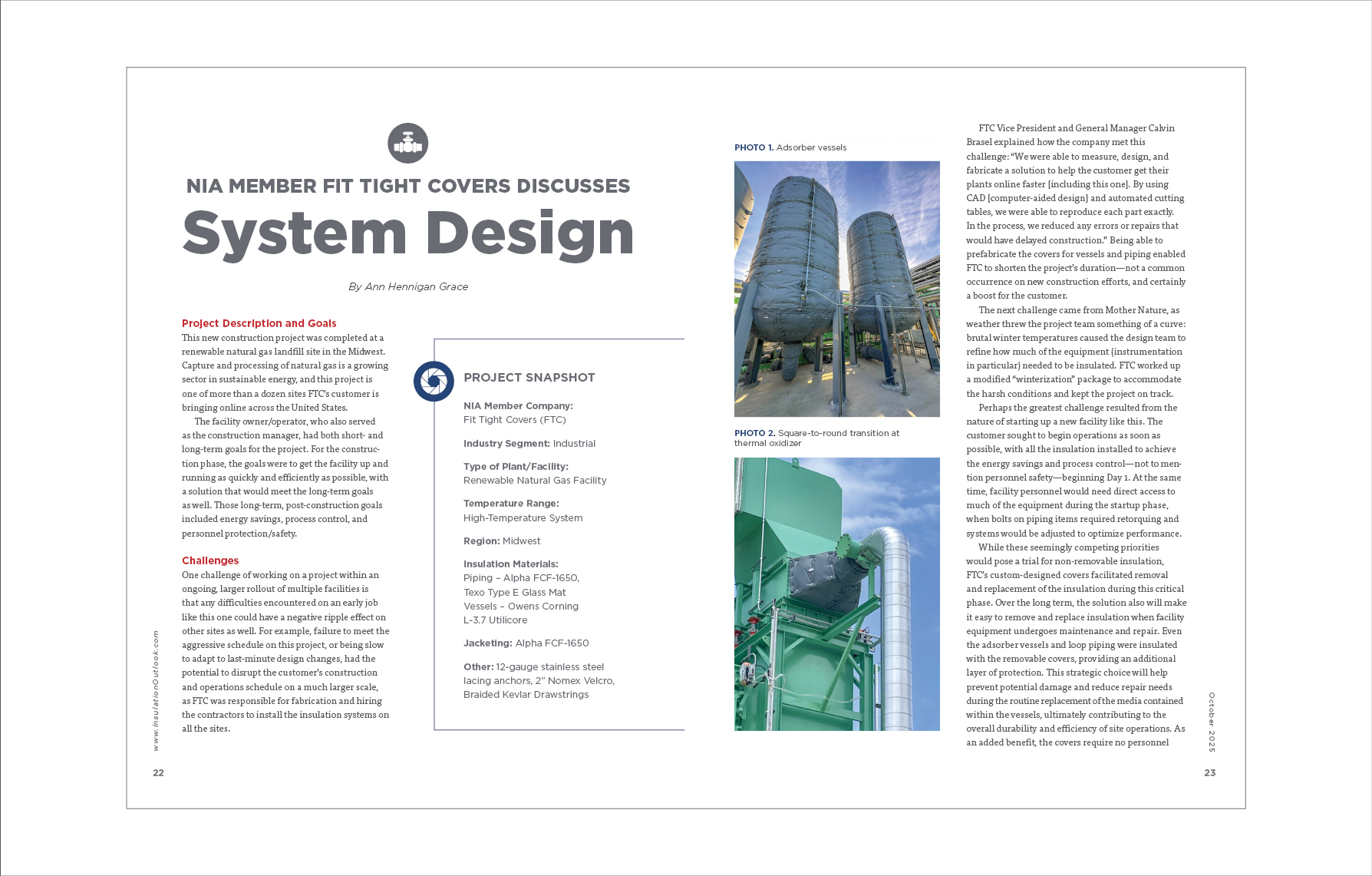

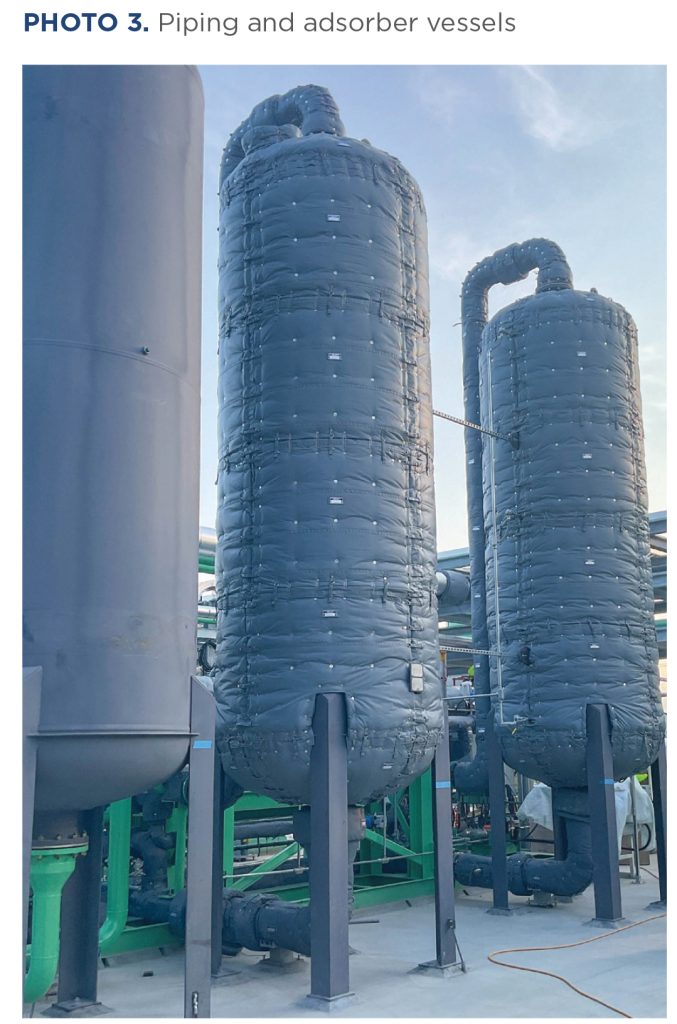

While these seemingly competing priorities would pose a trial for non-removable insulation, FTC’s custom-designed covers facilitated removal and replacement of the insulation during this critical phase. Over the long term, the solution also will make it easy to remove and replace insulation when facility equipment undergoes maintenance and repair. Even the adsorber vessels and loop piping were insulated with the removable covers, providing an additional layer of protection. This strategic choice will help prevent potential damage and reduce repair needs during the routine replacement of the media contained within the vessels, ultimately contributing to the overall durability and efficiency of site operations. As an added benefit, the covers require no personnel training to remove and replace. As Brasel notes, those working at this type of facility—many of whom have worked all over the world, including the Middle East—know the equipment well, so “working high-temperature Velcro and D-rings with straps, depending on the system,” is certainly within their skill set.

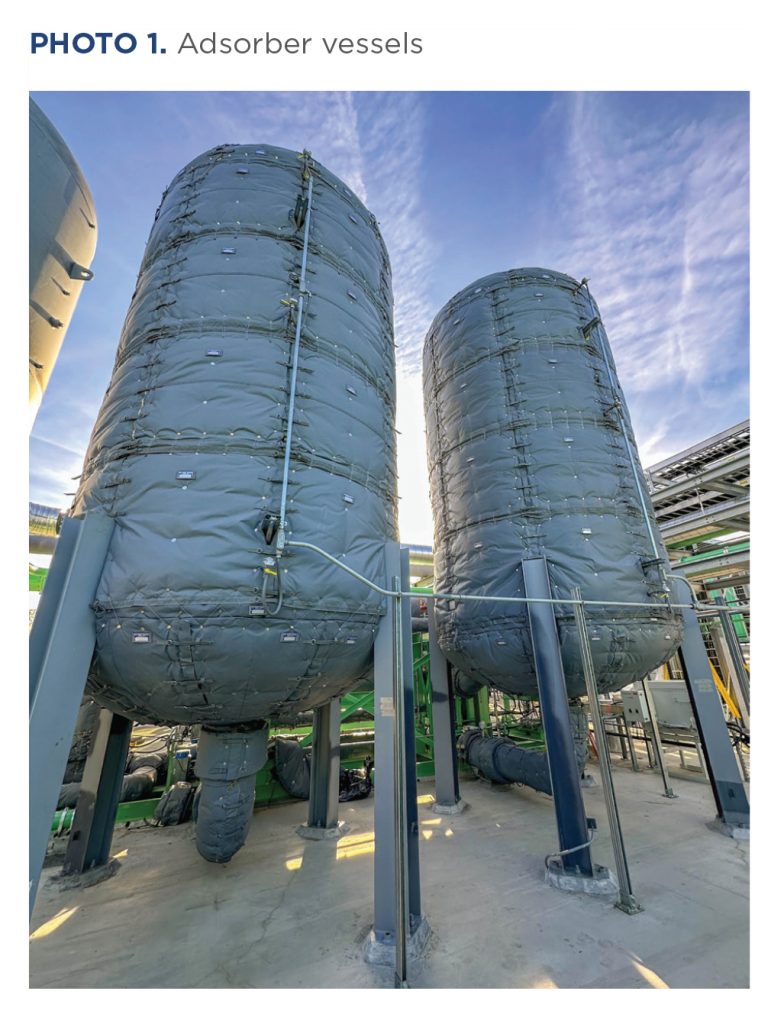

Photos 1 through 4 show the finished product.

FTC’s Solution

FTC recommended, and the owner/operator selected, removable insulation covers for all flanges, valves, and equipment to address concerns about startup costs and maintenance efficiency. The solution has the additional benefit of reducing waste—a critical consideration at a facility whose mission is sustainability. While hardcover conventional insulations must be discarded and replaced after being removed so plant personnel can perform inspections or maintenance, FTC’s removable blankets are designed to be easily reinstalled, which saves both landfill space and money for the facility owner.

For efficiency and quality assurance, FTC worked from component skids, fabricating and installing covers on the actual equipment before the components were shipped to the site. The skids included metal platforms containing all the piping to be mounted atop the vessels, as well as some of the smaller vessels. The project team took measurements from the skids, fabricated the removable covers, brought on installers, and shipped the skids out to the project site pre-insulated. Brasel notes, “The schedule is important to a client. When they start a site, they’re trying to condense the schedule to get the site operating as quickly as possible. An advantage of this approach is that a lot of the equipment shows up already insulated. With the exception of just a few parts—like large vessels—the site kit is already built. They don’t have to wait on a contractor to cut jacketing material or insulation.”

As alluded to earlier, the approach also provided quality assurance at the fabrication stage, as the CAD and automated cutting provided accurate, repeatable results. Because FTC sews its covers in the actual shape of the equipment—from a single valve to an entire piping system—the products fit the system perfectly. Finally, FTC performed quality control prior to releasing the skids, thoroughly inspecting each piece of equipment to ensure durable seams and complete insulation coverage.

Table 1 offers an overview of insulation system components, as well as product types and brands used. All materials and product types were selected for the temperature, weather, and chemical resistance properties. In addition to the ease of using Velcro for plant personnel, FTC’s covers require no wiring. Brasel notes, “Wiring can be a safety hazard—cutting it, it goes into the skin—and on the ground, it gets stuck in people’s boots.” Personnel protection is critical to this customer—which made insulating all the small pressure skids vital. Brasel explains, “The piping gets hot, and site personnel have to get around it to work on it, take the piping apart.”

Project Takeaways

Brasel says this project exemplifies a few themes common to most successful FTC projects.

Getting Insulation Experts Involved Early Saves Time and Money

FTC wrote the specifications for the entire insulation package—to include this site and all the others this customer is rolling out. This not only ensured an effective solution to meet all the short- and long-term performance objectives, but it also allowed seamless execution of the fabrication and installation. If a site required a slight change—e.g., if a bracket was moved to accommodate specific site conditions—FTC was able to adapt quickly.

Be Open to Good Ideas from All Sources

Calvin Brasel emphasizes that having an open mind and constantly learning and adapting is good for business—your own and your customers’. In this case, he says, “With industrial plants utilizing prefab skids to reduce cost and construction timelines, why not do the same thing with insulation?” As an added benefit, because FTC was capable of fabricating everything for the skids at its 20,000+ square foot facility in Evansville, Indiana, Brasel notes, “Our costs to fabricate the removable insulation covers for multiple sites did not vary or increase across the United States.”

Work with People You Trust

One theme that seems to run across all projects, when you have a job as important as this—remember, this project was just one of many sites for this customer, all with aggressive construction schedules—calling on companies you know you can count on is vital. FTC worked with several other NIA members to install this and similar projects:

- Caldwell Insulation, Inc.

- Gribbins Insulation & Scaffolding

- Insco Industries, Inc.

- Irex Contracting Group

FTC’s own project managers, CAD designers, and design engineer also deserve recognition for the company’s success on this project. Brasel says, “without everyone working on it, this would not have been a successful completion.”

Plan for Future Growth

One takeaway that may not immediately come to mind when one thinks of why a mechanical insulation project was successful is a company’s commitment and ability to plan to meet future requirements. The construction industry at large has been dealing with a labor shortage for years, and FTC has innovative strategies to grow the company’s personnel pipeline to keep pace with corporate growth. An internship program that draws from a local technical school, as well as local high schools, provides more potential talent each summer than the company can typically use. For students attending college, FTC brings interns in during school breaks, in addition to the summer. Brasel adds, “For full-time students in training, we work around their college class schedule.”

According to Brasel, “It takes 3 years training a fabricator to get to their full potential.” He adds, “We just hired a manufacturing engineer that we’re training in estimating.” The program is clearly paying off: Of six interns FTC has brought on board, all but one have stayed with the company while attending college and post graduation.

Pride in a Job Well Done

A second-place win in the NIA competition with highly qualified peers is extremely satisfying, and Calvin Brasel also takes tremendous pride in a job well done. “When you see the vessels, all the parts going together perfectly, 24 to 30 pieces assembled that fit that well, that’s what stood out on this project. You can see lots of blankets on piping systems, but those vessels, the tops of the vessels are like 32 feet up,” he marvels, concluding, “If it doesn’t fit right, it’s not Fit Tight.”

About Fit Tight Covers

FTC manufactures removable and reusable thermal insulation covers for commercial and industrial mechanical piping and equipment. The company is proud to be an insulation cover fabrication shop in the Midwest capable of servicing nationwide demand with the highest grade of removable insulation covers. With over 20,000 square feet of space and an experienced team of full-time fabricators, FTC can quickly and accurately produce any type of removable cover.

Please review their application pages for a sampling of some of the company’s work, as well as the materials available for certain specs and temperature requirements.