Vacuum Insulation Panels: High-Performance Building Envelope Insulation, Ideal for Retrofit Upgrades

Vacuum insulation panels (VIPs) are a thermally efficient insulation technology that has been in use for decades in specialty industries such as refrigeration, pharmaceuticals, and medical, and are now increasingly being considered for building envelope applications—particularly when maximizing insulation performance within a limited-thickness wall is critical.

About Vacuum Insulation Panels

VIP Construction

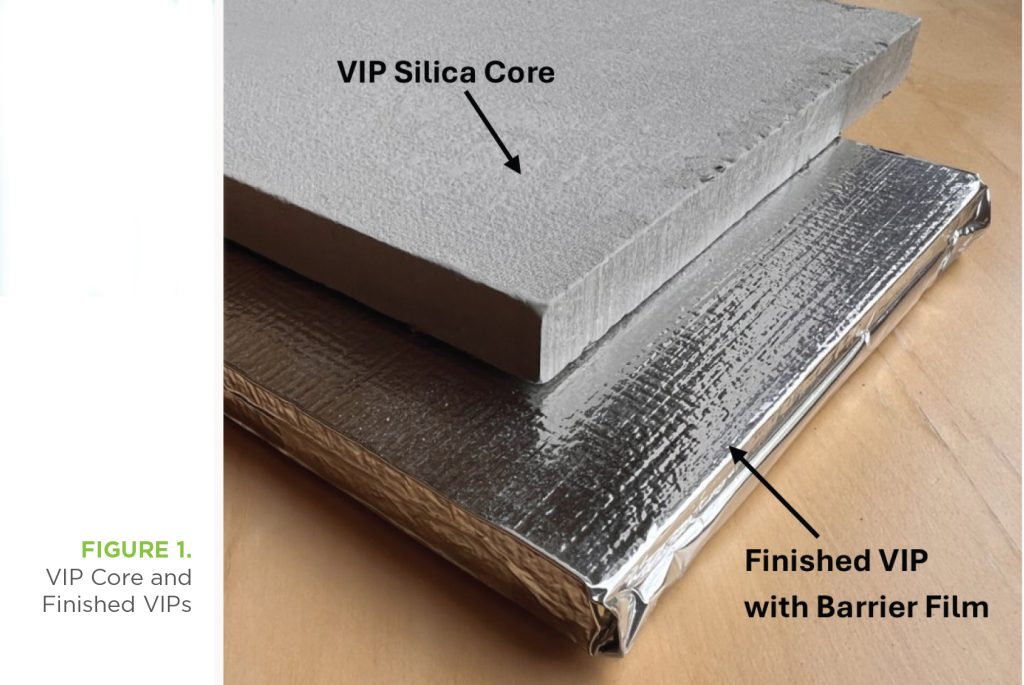

A VIP is essentially a highly insulating core material, sealed within an airtight, multilayer barrier film, with the air inside removed to create a deep vacuum. Each component plays a role in its exceptional performance (see Figure 1).

- Core Material

Typically made of pyrogenic silica or fine glass fibers, the core has an extremely fine pore structure (under 60 nanometers). This structure limits the ability of air molecules to transfer heat, even before the vacuum is applied. The core is also designed to resist compression under the high loads it will encounter when the vacuum is applied. - Barrier Film

The barrier is a multilayer laminated plastic film with thin metal coatings that block the passage of gases and moisture. It is engineered to have both low gas permeability and the ability to be heat sealed. - Vacuum Environment

During manufacturing, the air inside the panel is evacuated to a pressure of less than 0.07 PSI (5 millibar)—about 1/200th of normal atmospheric pressure. This drastically reduces air conduction and convection through the core. - Edge Protection

VIP edges, where the barrier film seams exist, are then sealed by heat-welding, leaving folded “flaps.” These are folded flat or taped to minimize heat transfer at the edges (called “edge effects”), which is higher than through the panel’s center.

The result is an insulation product with thermal conductivity as low as 0.027 BTU-in/hr-ft2°F (0.004 W/m·K) in fresh, undamaged panels—about one-fifth that of common foam insulations. In practical terms, a 1-inch VIP can deliver R-35 or more.

Benefits

VIPs offer several advantages in building applications.

- High Thermal Performance in Minimal Thickness

This is particularly valuable where space is constrained—for example, in retrofits where thickening the walls can complicate finishing of window and door openings. - Significant Energy Savings Potential

By raising the effective wall R-value dramatically, VIPs can cut heating and cooling demand in both new and existing buildings. - Applicability in Continuous Insulation Systems

Continuous insulation on the exterior side of the structure minimizes thermal bridging from studs and other framing members. - Long Service Life

With proper design and installation, VIPs can maintain superior performance for 25 years or more.

Applications

VIPs are already used in many applications.

- Buildings—for walls, roofs, and floors in high-performance designs

- Appliances—refrigerators, freezers, and specialty coolers

- Cold-Chain Logistics—insulated packaging for perishable goods

- Specialized Sectors—medical, laboratory, and defense applications

Challenges

While VIPs have impressive performance, they also present certain challenges.

- Higher Cost

On a per-R-value basis, VIPs currently cost more than traditional insulation. Costs may come down with new materials and production technologies. - Handling Fragility

If the barrier film is punctured, the vacuum is lost, and thermal performance drops (though the core still insulates slightly better than rigid foam). - Standardized Sizing Available Only

Panels cannot be cut to fit on site, so designs must accommodate fixed panel dimensions. - Gradual Aging

Over time, small amounts of air may leak in, slowly reducing thermal performance over many years.

Retrofit Building Application Potential

Approximately 48% of buildings in the United States were built before 1980, often with insulation levels far below current energy codes. Retrofitting these structures can have a large impact on reducing overall energy consumption, particularly in climates with high heating or cooling loads.

Exterior continuous insulation is one of the most effective retrofit strategies because it:

- Covers structural elements, reducing thermal bridging;

- Improves the effective R-value of the whole wall assembly; and

- Can be installed without major disruption to interior spaces.

VIP-based retrofit systems combine high performance with minimal added thickness. For example:

- Adding just 3.5 inches of a VIP/foam composite can triple or quadruple the thermal resistance of a typical 2×4 wall assembly.

- Even modest thickness systems can meet or exceed Passive House wall performance targets.

One practical approach is a VIP-foam sandwich panel system, mounted to the exterior over existing sheathing, or direct to studs, and secured using pultruded fiber glass z-girts. These girt members are much less conductive than steel, greatly reducing heat loss at attachment points. The z-girts also allow the attachment of exterior cladding systems without puncturing the VIPs with fasteners.

Performance and Durability Testing

A National Research Council of Canada (NRC) study1 tested a steel stud wall fitted on the exterior with a VIP- and foam-based composite insulation system to evaluate both performance and durability. Thermal performance testing was conducted using a guarded hot box apparatus in accordance with ASTM C1363, “Standard Test Method for Thermal Performance of Building Materials and Envelope Assemblies by Means of a Hot Box Apparatus.”

Wall Construction

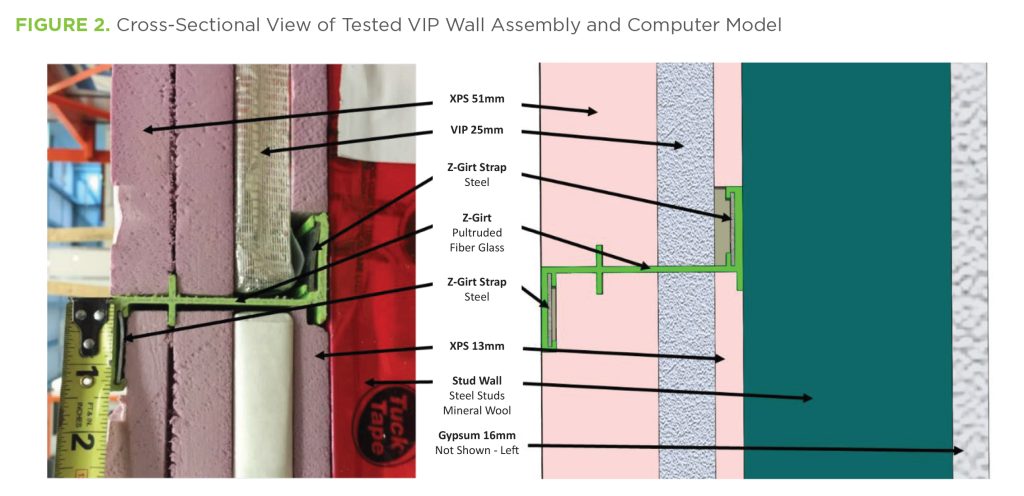

The test wall consisted of:

- Interior Layer—3.5-inch steel studs filled with mineral wool

- Exterior Layer—3.5-inch VIP/extruded polystyrene (XPS) foam sandwich panels

- Attachment System—fiber glass z-girts, spaced 24 inches apart, holding the cladding and insulation

This buildup created a total wall thickness of 7.75 inches yet delivered R-38—far above typical code-minimum values.

Thermal Performance

- Testing was conducted at extreme temperature differences: interior at 70°F (21°C) and exterior at -4°F and -31°F (-20°C and -35°C).

- A 3D finite element analysis (FEA) computer model was also created of the tested wall construction. The wall’s tested thermal performance (overall R-value) matched computer simulations within 2.5%, validating the modeling method.

- The protective foam layers not only prevented accidental VIP damage during installation, but also contributed to thermal resistance.

Figure 2 shows a cross section of the tested wall assembly and the computer model. The cross section shows the VIP and the XPS foam layers, along with the z-girt support. The system used two layers of XPS to sandwich and protect the VIP. A ½-inch (12.7 mm) layer was used against the steel studs to prevent puncture of the barrier film by any sharp edges of the steel studs. A 2-inch (51 mm) layer was applied outboard of the VIP, which allowed the use of screws to attach cladding to the z-girt supports without penetrating the VIP. The VIP edges were covered with thin, puncture-resistant films for additional protection during assembly.

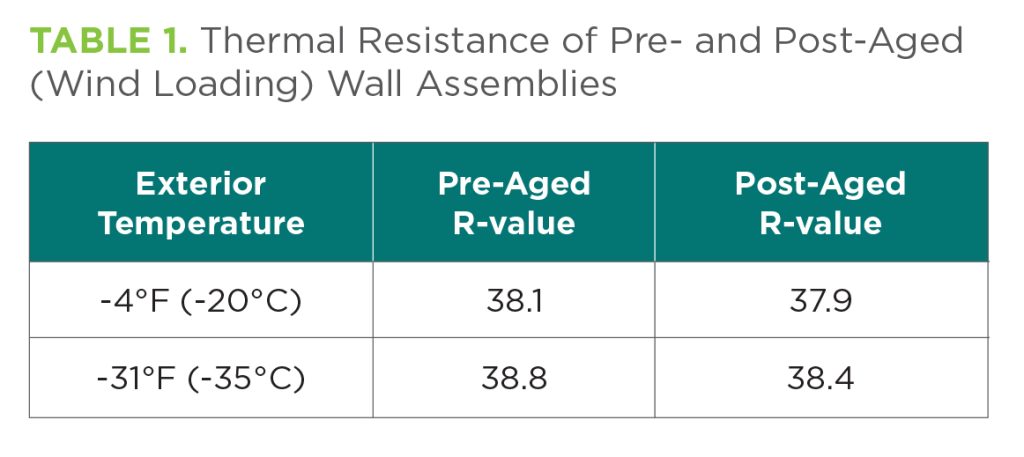

Durability Testing

The NRC subjected the wall to a wind-load aging protocol, then retested the wall’s thermal performance in the hot box apparatus. The protocol included sustained, cyclic, and gust loads. The wall retained its high R-value, demonstrating that properly protected VIPs are suitable for long-term building applications. The results of the performance testing before and after the wind loading are shown in Table 1.

Variable Construction Modeling

With the validated simulation model, multiple alternative designs were analyzed to see how thickness, VIP coverage, and attachment materials affected performance.

Thickness Performance

Three exterior insulation thicknesses were modeled:

- 2 inch (51 mm)—compact, minimal intrusion on openings, but only moderate gains over foam alone, with a 1-inch (25 mm) VIP yielding R-25 versus R-18 with foam alone.

- 3.5 inch (89 mm)—balanced solution with a 1-inch (25 mm) VIP, achieved R-38 and suitable for most retrofits.

- 5 inch (127 mm)—high-performance option with a 2-inch (50 mm) VIP; achieved up to R-57, ideal for Passive House or very cold climates.

The simulations showed that as insulation thickness increases, thermal bridging from girts becomes less significant relative to the total wall performance, but only if low-conductivity girts are used.

Coverage Impacts

Because VIPs can’t be cut to fit irregular areas, foam alone is used in gaps around openings and edges. Additionally, even with foam protection, an improperly driven nail or screw could compromise an isolated VIP’s vacuum. Modeling showed:

- 25% non-VIP coverage area could reduce R-value by up to 20 to 23% in high-thickness VIP designs.

- Damaged VIPs (loss of vacuum) still insulate as well or slightly better than foam, mitigating worst-case losses.

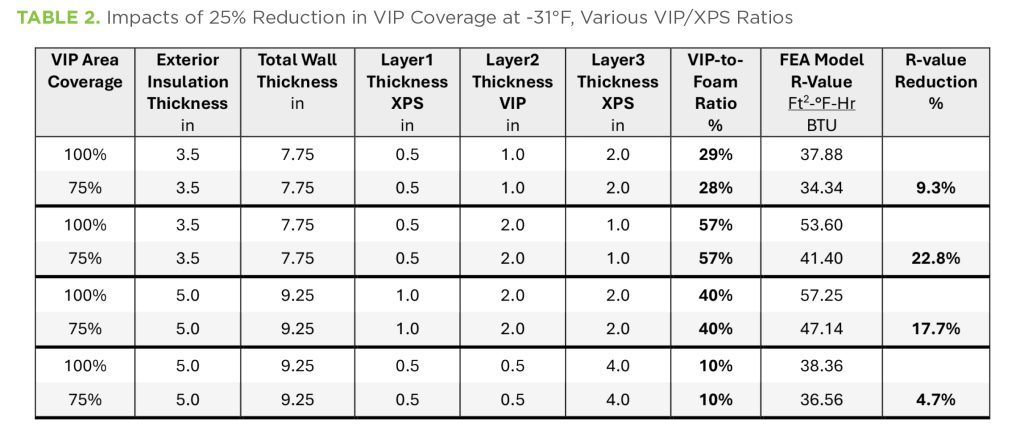

Table 2 shows the effects of a 25% reduction in VIP coverage in the event of damaged VIPs or poor fit of VIP shapes around the building fenestration. Two exterior insulation thicknesses were analyzed with different ratios of VIP thickness to foam thickness.

Effect of Support Materials

Changing the attachment system from pultruded fiber glass z-girts to steel z-girts had a dramatic impact:

- In high-performance walls, R-value dropped by almost 60% due to thermal bridging.

This confirms the importance of low-conductivity structural supports in any high-R-value wall system.

Comparison to Conventional Walls

A standard 3.5-inch steel stud wall with mineral wool (or fiber glass) and OSB sheathing has an effective R-value of about R-8.4. The R-value is much less than the fiber-based insulation alone due to the thermal bridging of the structural elements.

- Adding 0.5 inches of XPS foam sheathing raises it to an R-value of R-11.7.

- Adding a 3.5-inch VIP/foam composite system instead can boost it to R-38—more than tripling thermal resistance.

- A 5-inch VIP/foam system can reach R-57, a nearly five-fold improvement.

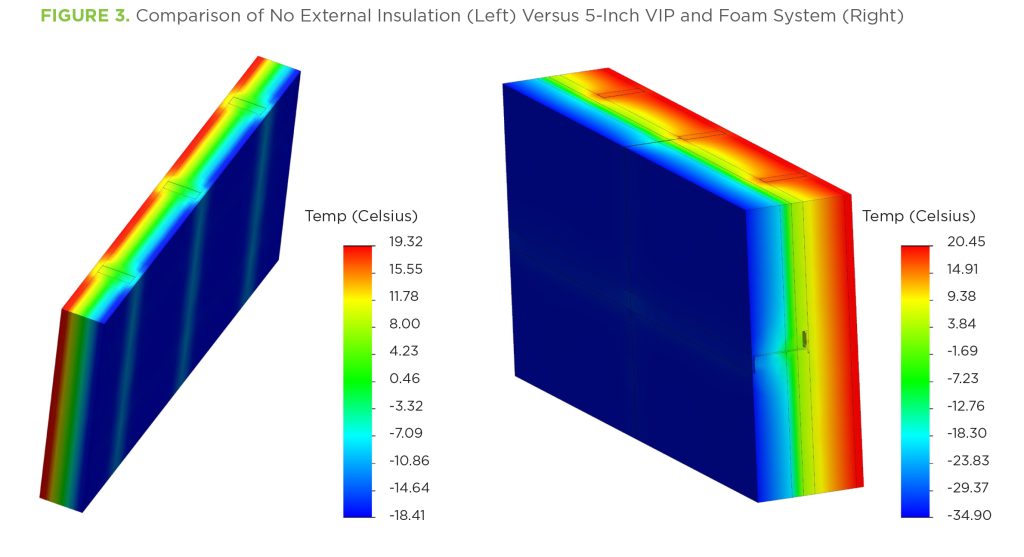

Figure 3 compares models of the two extremes: a 3.5-inch steel stud wall with mineral wool insulation, OSB sheathing, and no external insulation (R-value 8.4) versus the same wall with no OSB and a 5-inch VIP-and-foam composite external insulation system (R-value 57). Especially visible is the difference at the steel studs, where high levels of heat bridging occur in walls with no external insulation. The VIP and foam wall is just over twice as thick (4.25 inches versus 9.25 inches) but provides seven times the insulating value.

Conclusion

VIPs bring lab-grade thermal performance into the realm of building construction. In retrofit applications, they offer the rare combination of:

- High R-value in minimal thickness;

- Long-term durability and performance, when properly protected; and

- Flexibility in combination with other insulation types.

Key takeaways from this VIP performance study are as follows.

- Validated Modeling—simulation results matched full-scale hot box tests within 2.5%.

- Thickness Matters—optimal retrofit performance is achieved with 3.5 to 5 inches of an exterior VIP/foam composite system.

- Support Systems Are Critical—low conductivity girts are essential to preserve gains from high-performance insulation.

- Coverage Gaps Reduce Performance Slightly—areas without VIPs can reduce overall wall efficiency in high-VIP designs but still perform well above conventional assemblies.

As manufacturing costs decrease and designs improve, VIP systems are likely to become a standard tool for architects and engineers aiming for net-zero and Passive House performance standards in both new and existing buildings.