The Building Envelope: Codes, Codes, and More Codes

The metal building industry has witnessed a tremendous shift over the last several years. Increasingly stringent energy codes have propelled the industry toward more sustainable construction and innovation that we wouldn’t have imagined a few decades ago. An entirely new vocabulary is used when talking about metal buildings: “conditioned space,” “climate zones,” “air barriers,”—30 years ago this was all unheard of. Additionally, newer energy codes contain higher performance expectations, which not only require more insulation, but also call for more advanced systems, such as air barrier systems, liner systems, and more.

This metal building industry update is designed to cover the most recent building envelope changes within the latest code cycles and the specific insulation system innovations that meet the latest codes. Before that, I will briefly review some metal building energy code basics.

The Difference between ASHRAE and IECC

First, ASHRAE 90.1 is a minimum Standard of energy efficiency, not a code. The International Energy Conservation Code (IECC) is a model energy code that references the ASHRAE 90.1 Standard. Other differences include:

- ASHRAE 90.1 and IECC have different 3-year cycles.

- IECC follows behind ASHRAE 90.1 by 2 years. For example, IECC 2012 references ASHRAE 90.1-2010. IECC 2015 references ASHRAE 90.1-2013.

- IECC adopts the latest ASHRAE Standard, plus any addendums and new data. This means that IECC is ultimately a more stringent code than the ASHRAE Standard.

What’s in an Energy Code?

There are 3 major components of an energy code:

- Lighting;

- HVAC; and

- Envelope.

Additionally, there are many elements within the building envelope subject to energy code regulations:

- Opaque roof and wall assemblies;

- Windows;

- Skylights;

- Doors;

- Foundation; and

- Floor.

This article focuses on changes to roof and wall assembly code requirements, but remember that there are updates to other elements of the building envelope that you should also be aware of.

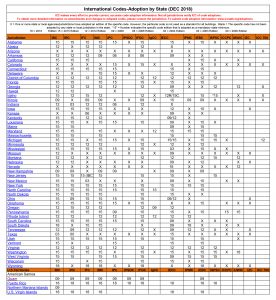

Code Adoption by State

The resources we use for state code changes include the Department of Energy (DOE), the Building Codes Assistance Project (BCAP), and the International Code Council (ICC). The chart above, which is a comprehensive list of codes adoptions in each state, is current as of December 2018. You can think of this as a guideline to help determine which adoptions have been made in your state.

The Newest Code Cycle: IECC 2018/ASHRAE 90.1-2016

In January, I attended the ASHRAE meeting in Atlanta, where we worked on the final stages of the 2019 ASHRAE 90.1 Standard. While that isn’t quite ready for publishing yet, the 2016 Standard is out and ready for adoption. Thus, we refer to IECC 2018/ASHRAE 90.1-2016 as the “newest” code cycle. While a handful of cities throughout the country have adopted it, no statewide adoptions have been made yet.

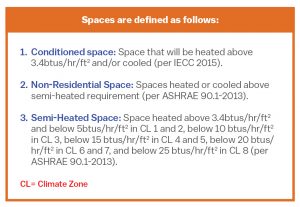

In terms of updates, you can expect to see the majority of changes in air sealing and blower door testing. Additionally, there’s a reduced BTU table for semi-heated space. This means that the maximum allowable heat output per climate zone has been reduced, thus making the semi-heated compliance path more difficult to use. Remember that these comparisons are based off of IECC 2015/ASHRAE 90.1-2013.

The Most Widely Adopted “New” Code: IECC 2015/ASHRAE 90.1-2013

The most widely adopted “new” code cycle is IECC 2015 and ASHRAE 90.1-2013. If your current state’s code is based on the IECC 2009/ASHRAE 90.1 2007 Standard, you’ll see the most significant envelope changes. Many states currently at the IECC 2009 code are bypassing IECC 2012 altogether (or have already done so) and are adopting IECC 2015. Pennsylvania and South Carolina are examples of this. On October 1, 2018, Pennsylvania changed from IECC 2009/ASHRAE 90.1-2007 to the IECC 2015/ASHRAE 90.1 2013 code. South Carolina did the same as of January 1, 2019. This is a huge jump, and many metal building contractors will feel the pressure. If you haven’t used Liner Systems or Filled Cavity/Long Tab Banded Systems in the past, you will need to start using them. Both options fulfill the metal building insulation requirements—it’s just a matter of preference. I detail the key differences between the systems later on in this article.

Highlights of the IECC 2015/ASHRAE 90.1-2013 cycle include:

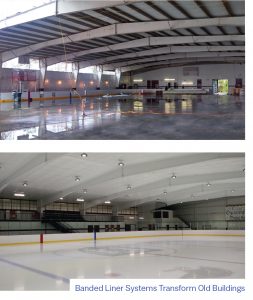

- Higher insulation values: IECC 2015 and ASHRAE 90.1-2013 have the most stringent envelope requirements based on “Conditioned Space” and “Non-Residential Space.” This means that, for the most part, contractors will need to use Banded Liner Systems or Long Tab Banded Systems in order to meet the stricter insulation requirements.

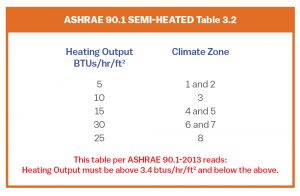

Table 3.2 (below), which is used for determining semi-heated space, has not changed from older code cycles to this one.

If semi-heated is not allowed based on the heating system or jurisdiction, then each climate zone will have major increases in thermal performance, which translates to increased insulation levels under the non-residential space. This is based on the ASHRAE 90.1-2013 Standard; however, the IECC 2015 code has, for the most part, the same values. For example, using ASHRAE 90.1-2013, climate zone 5a requires a roof U-Value of .037 and a wall U-value of .050. In order to obtain these U-values, a metal building would require either a Liner System or Filled Cavity/Long Tab Banded System for the roof, and a Liner System Filled Cavity for the walls.

- Air barrier requirement: Both IECC 2015 and ASHRAE 90.1-2013 require an air barrier in the thermal envelope, and for it to be indicated in drawings. It can be placed on the interior side, exterior side, somewhere within assemblies composing the envelope, or any combination thereof.

- In IECC 2015, this can be found in section C 402.5.1 and C 402.5.1.1. (exceptions = unheated buildings)

- In ASHRAE 90.1-2013, it’s found in section 5.4.3, 5.4.3.1.1, and 5.4.3.1.2. (exceptions = semi-heated buildings in climate zones 1-6)

It is also mandatory to identify the air barrier and for it be continuous across joints and assemblies. Joints and seams must be sealed and securely installed. Penetrations and joints—and seals associated with penetrations—must be sealed in a manner compatible with construction material and location. These must be shown on the drawings submitted for permitting.

- Compliance path: Under the IECC 2015 Code and ASHRAE 90.1-2013 Standard, it’s still the same choice. The designer decides to follow one of 3 paths: Materials, Assembly, or Whole Building. The materials path is just that—any material tested under ASTM E 2178.Assembly is a combination of envelope materials built and tested under ASTM E 2157, 1677, or 283. Whole building testing requires ASTM E 779. If this option is used, and the building fails, it must be brought in compliance with the leakage rate allowed. This means that you cannot opt out of this path once it’s chosen by the designer. ASHRAE 90.1-2013 does allow a lesser leakage rate if repairs are made.

- States that have adopted IECC 2015/ASHRAE 90.1-2013 include: Alabama, California, Illinois, Maryland, Massachusetts, Michigan, New Jersey (adopted ASHRAE 90.1-2013), New York, Oregon, Utah, Texas, Vermont (state-specific code modeled after IECC 2015), and Washington. Georgia is also slated to adopt the code cycle over the next few months.

The Biggest Question to Answer in 2019: “What Do I Need to Meet Code?”

As we move toward more complexity in each code cycle, this longstanding question will only become even more common. As simple as the question is, it is very difficult to answer. In short, the compliance path I recommend most often is the prescriptive approach. Per the U.S. Department of Energy, the prescriptive approach includes “requirements that either must be met by every building design, or if the requirement is not met, a tradeoff must be made to make up for not meeting that requirement.” In other words, you must meet all U-values of the roof, walls, foundation, and fenestrations. If a tradeoff is indeed needed in the end, the quoted price has covered any changes.

Closing Remarks

In closing, the code cycle changes that are either here or coming soon to your state are, without a doubt, challenging to say the least. As insulation suppliers located throughout the country, we’ve had to attend meetings, learn, and be involved with the entire process of code development. This it to assure our customers are providing code-compliant envelopes to the their customers and, on a bigger level, the metal building industry. Overall, it’s been a good year for metal building construction. The newest code changes mean more efficient buildings and more innovative solutions that have greater potential to save end users money.

Copyright Statement

This article was published in the February 2019 issue of Insulation Outlook magazine. Copyright © 2019 National Insulation Association. All rights reserved. The contents of this website and Insulation Outlook magazine may not be reproduced in any means, in whole or in part, without the prior written permission of the publisher and NIA. Any unauthorized duplication is strictly prohibited and would violate NIA’s copyright and may violate other copyright agreements that NIA has with authors and partners. Contact publisher@insulation.org to reprint or reproduce this content.