Exploring Insulation Materials

Polyisocyanurate

Polyisocyanurate

thermal insulation (PIR) is rigid foam insulation, with a closed cell

structure. It is usually manufactured as large rectangular buns, typically 4 ft

wide x 3-24 ft long x 1-2 ft tall, in a range of densities and compressive

strengths. Prior to actual installation, buns are fabricated into various

shapes, including flat boards and preformed pipe half-shells 3-4 ft long,

designed to fit NPS pipe and tubing. Complex shapes can also be fabricated to

fit around valves, fittings, and other equipment. ASTM material specification C

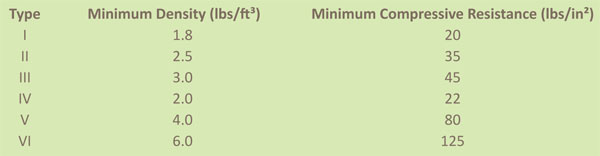

591 covers PIR at service temperatures from -297°F to 300°F. ASTM C 591

contains requirements for density, compressive resistance, thermal

conductivity, water absorption, water vapor permeability, dimensional

stability, closed cell content, and hot-surface performance. This ASTM

specification lists two grades and six types, with the types identifying the

various densities noted below. The most commonly used densities are in the

2-2.5 lb/ft³ range (types IV and II). For comparison purposes, the thermal

conductivity of the Grade 2, Types IV and II PIR, is a maximum of 0.20

Btuin/(hrft²°F) at 75°F.

The two grades, 1 and 2, identify PIR designed for

different temperature ranges. Grade 1 has a temperature range of -70°F to

300°F; while Grade 2 has a temperature range of -297°F to 300°F.

Key

applications for PIR insulation are on pipe, equipment, tanks, and ducts,

operating at temperatures below ambient. Examples include commercial chilled

water, refrigeration, and liquefied natural gas lines. It is also used as the

core material in the manufacture of foam core panels for various applications,

including transportation, building construction, and temporary shelters.